Composite ceramsite prepared from bentonite, perlite and zeolite serving as main raw materials and preparation method of composite ceramsite

A technology of expanded perlite as the main raw material, applied in chemical instruments and methods, ceramic products, silicon compounds, etc., can solve the problems of high energy consumption and low capacity, achieve long life, large adsorption capacity, and realize the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

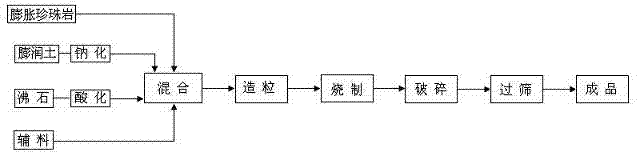

Method used

Image

Examples

Embodiment 1

[0036] The main raw materials are expanded perlite, sodium bentonite and natural zeolite, and clay and polyethylene glycol are used as auxiliary materials. Weigh respectively: 500g of expanded perlite (60-80 mesh), 200g of sodium bentonite, 150g of acidified zeolite, 50g of clay, and 50g of polyethylene glycol.

[0037] The bentonite, zeolite and clay were crushed to 200 mesh respectively.

[0038] The above-mentioned main and auxiliary materials were fully mixed in a mixing agitator for 60 minutes.

[0039] Put the mixed material into the rotary disc granulator to granulate, and the particle size is controlled at 10~150mm.

[0040] The pellets are sintered in the air atmosphere of a high temperature furnace. First raise the temperature to 200°C, dehydrate and dry under this condition for 60 minutes; continue to raise the temperature to 600~800°C, and keep it warm for 120 minutes.

[0041]The sintered material is naturally cooled to 25°C, and crushed into spherical or cylin...

Embodiment 2

[0043] The main raw materials are expanded perlite, sodium bentonite and natural zeolite, and clay and gelatin are used as auxiliary materials. Weigh respectively: expanded perlite (60-80 mesh) 300g, sodium bentonite 200g, acidified zeolite 250g, clay 50g, gelatin 50g.

[0044] The bentonite, zeolite and clay were crushed to 200 mesh respectively.

[0045] The above-mentioned main and auxiliary materials were fully mixed in a mixing agitator for 50 minutes.

[0046] Put the mixed material into the rotary disc granulator to granulate, and the particle size is controlled at 10~150mm.

[0047] The pellets are sintered in the air atmosphere of a high temperature furnace. First raise the temperature to 250°C, dehydrate and dry under this condition for 50 minutes; continue to raise the temperature to 650~900°C, and keep it warm for 120 minutes.

[0048] The sintered material is naturally cooled to 25°C, and crushed into spherical or cylindrical particles with a particle size of 5...

Embodiment 3

[0050] Sodium bentonite, expanded perlite and natural zeolite are used as main raw materials, and clay and polyacrylamide are used as auxiliary materials. Weigh respectively: 250g of sodium bentonite, 350g of expanded perlite (40-60 mesh), 200g of acidified zeolite, 60g of clay, and 50g of polyacrylamide.

[0051] The bentonite, zeolite and clay were crushed to 200 mesh respectively.

[0052] The above-mentioned main and auxiliary materials were fully mixed in a mixing agitator for 60 minutes.

[0053] Put the mixed material into the rotary disc granulator to granulate, and the particle size is controlled at 10~150mm.

[0054] The pellets are sintered in the air atmosphere of a high temperature furnace. First raise the temperature to 300°C, dehydrate and dry under this condition for 40 minutes; continue to raise the temperature to 600~700°C, and keep it warm for 120 minutes.

[0055] The sintered material is naturally cooled to 25°C, and crushed into spherical or cylindrica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com