Reflection gain type high-power laser device

A high-power laser, reflection gain technology, applied in the field of lasers, can solve the problems of concentration quenching, difficulty in ensuring uniformity, and difficulty in increasing the upper limit of laser power, and achieve the effect of high output power upper limit and increased energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

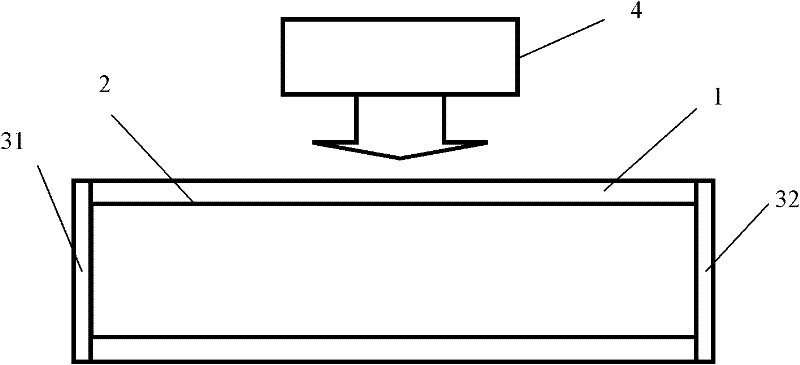

[0022] A reflective gain type high-power laser, the laser includes a quartz tube 1 , a gain coating 2 on the inner wall of the tube, a total reflection mirror 31 , a partial reflection mirror 32 , and a pump source 4 .

[0023] The material of the gain coating 2 on the inner wall of the tube is ytterbium ion, and the thickness of the gain coating 2 on the inner wall of the tube is 10 nm.

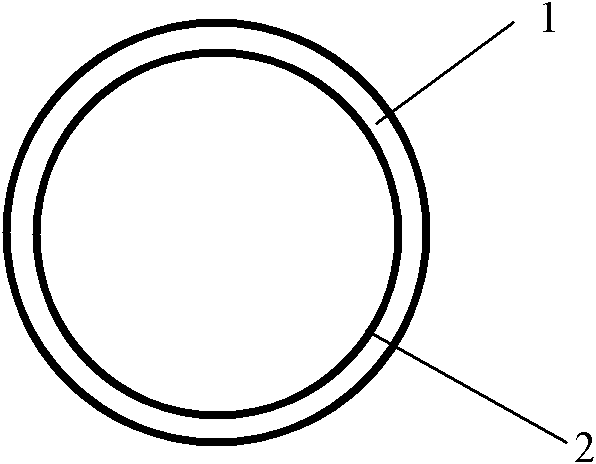

[0024] The cross-sectional shape of the quartz tube 1 is that the inner and outer walls are circular, such as figure 1 , 2 shown.

[0025] The gain coating 2 on the inner wall of the tube totally reflects the generated laser signal.

[0026] The total reflection mirror 31 totally reflects the generated laser signal.

[0027] The reflectivity of the partial reflector 32 to the generated laser signal is 4%.

[0028] The pumping source 4 directly irradiates the quartz tube 1 from the side, and the direct irradiation means that the pump light generated by the pumping source 4 enters the quar...

Embodiment approach 2

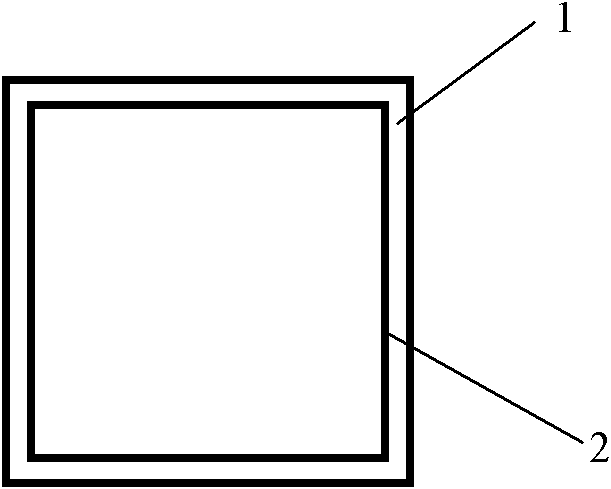

[0030] The difference between Embodiment 2 and Embodiment 1:

[0031] The inner and outer walls of the cross-sectional shape of the quartz tube 1 are rectangular, such as image 3 shown.

[0032] The material of the gain coating 2 on the inner wall of the tube is erbium ion, and the thickness of the gain coating 2 on the inner wall of the tube is 30nm.

[0033] The reflectivity of the partial reflector 32 to the generated laser signal is 96%.

Embodiment approach 3

[0035] The difference between Embodiment 3 and Embodiment 1:

[0036] The inner wall of the cross-sectional shape of the quartz tube 1 is star-shaped, and the outer wall is circular, such as Figure 4 shown.

[0037] The material of the gain coating 2 on the inner wall of the tube is neodymium ion, and the thickness of the gain coating 2 on the inner wall of the tube is 60nm.

[0038] The reflectivity of the partial reflector 32 to the generated laser signal is 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com