Energy-saving electromagnetic clutch

A technology of electromagnetic clutches and stator housings, applied in clutches, magnetic drive clutches, non-mechanical drive clutches, etc., can solve problems such as slow assembly efficiency, achieve volume and weight reduction, reduce the loss of electromagnetic force, and have obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

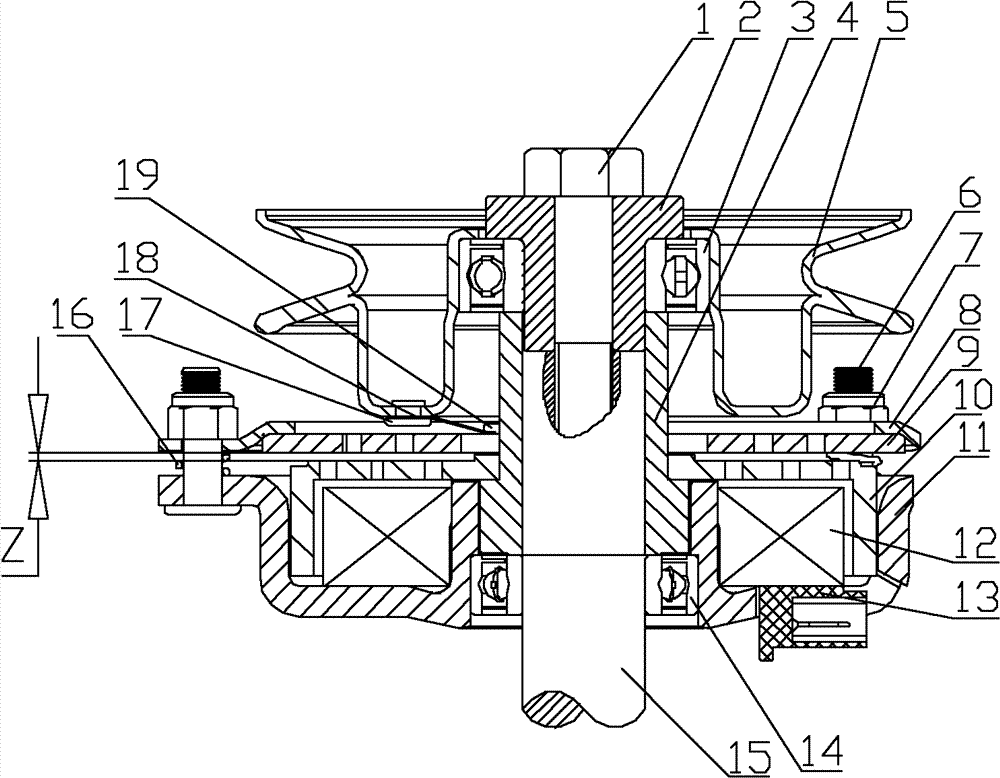

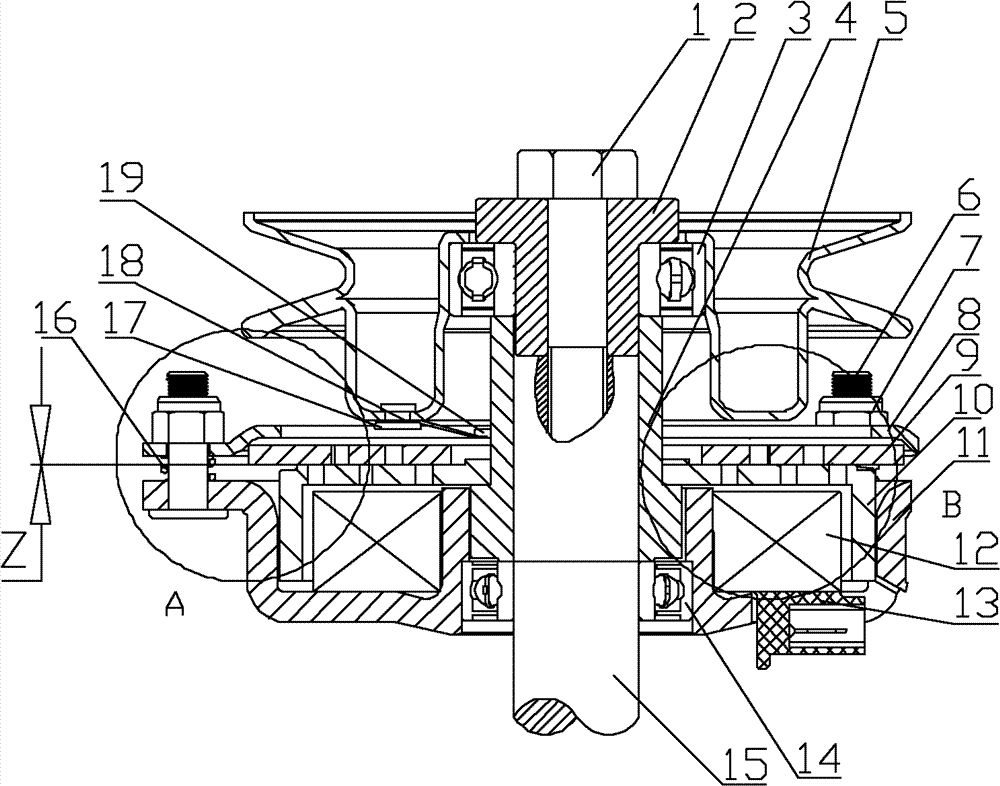

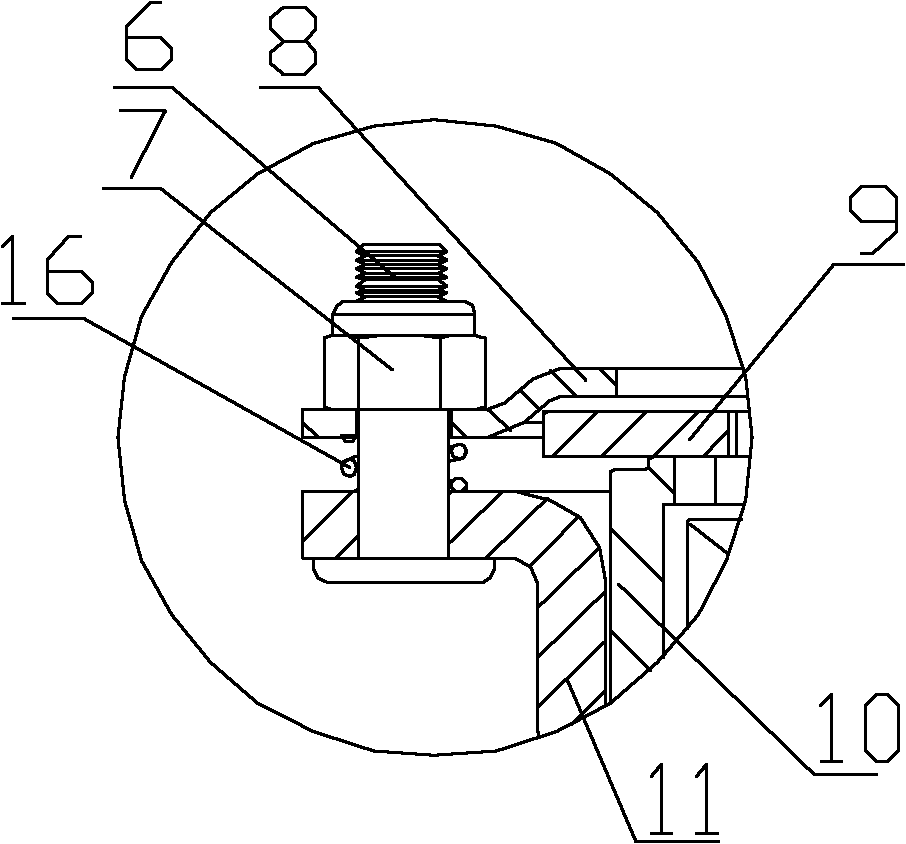

[0027] Such as Figure 1 to Figure 8 As shown, an energy-saving electromagnetic clutch includes a support bolt 6, a tie nut 7, a brake disc cover 8, a leaf spring 18, an armature 9, a rotor 10, and a stator housing 11. The brake disc cover 8 passes through the support bolt 6. The tightening nut 7 is fixed on the stator housing 11, the armature 9 is located between the brake disc cover 8 and the stator housing 11, the brake disc cover 8 and the stator housing A compression spring 16 is provided between the bodies 11, and the compression spring 16 is sleeved on the supporting bolt 6, the rotor 10 is installed in the stator housing 11, and the side wall end surface of the rotor 10 and the stator housing The end surface of the inner side wall of the body 11 is provided with a gap, the stator housing 11 is also provided with a coil 12, the coil 12 is riveted in the stator housing 11, and the end surface of the ring groove of the stator housing 11 is provided with an outward convex ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com