Heating device for improving heating quality of steel billets and using method thereof

A heating equipment and billet heating technology, applied in the field of steel rolling heating in the iron and steel industry, can solve the problems of decreased technical performance, increased maintenance times, reduced energy saving effect, etc., and achieve the effects of optimizing fuel consumption, reducing burning loss, and reducing overburning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] In the present invention, one pair of flat flame burners and three pairs of regenerative burners are respectively installed in the soaking section and the heating section, and three pairs of regenerative burners on each side form a regenerative burner group. The valve controls a regenerative burner group. The initial parameters of this implementation case are shown in Table 1.

[0066] Table 1 Initial parameters of this implementation case

[0067]

[0068]

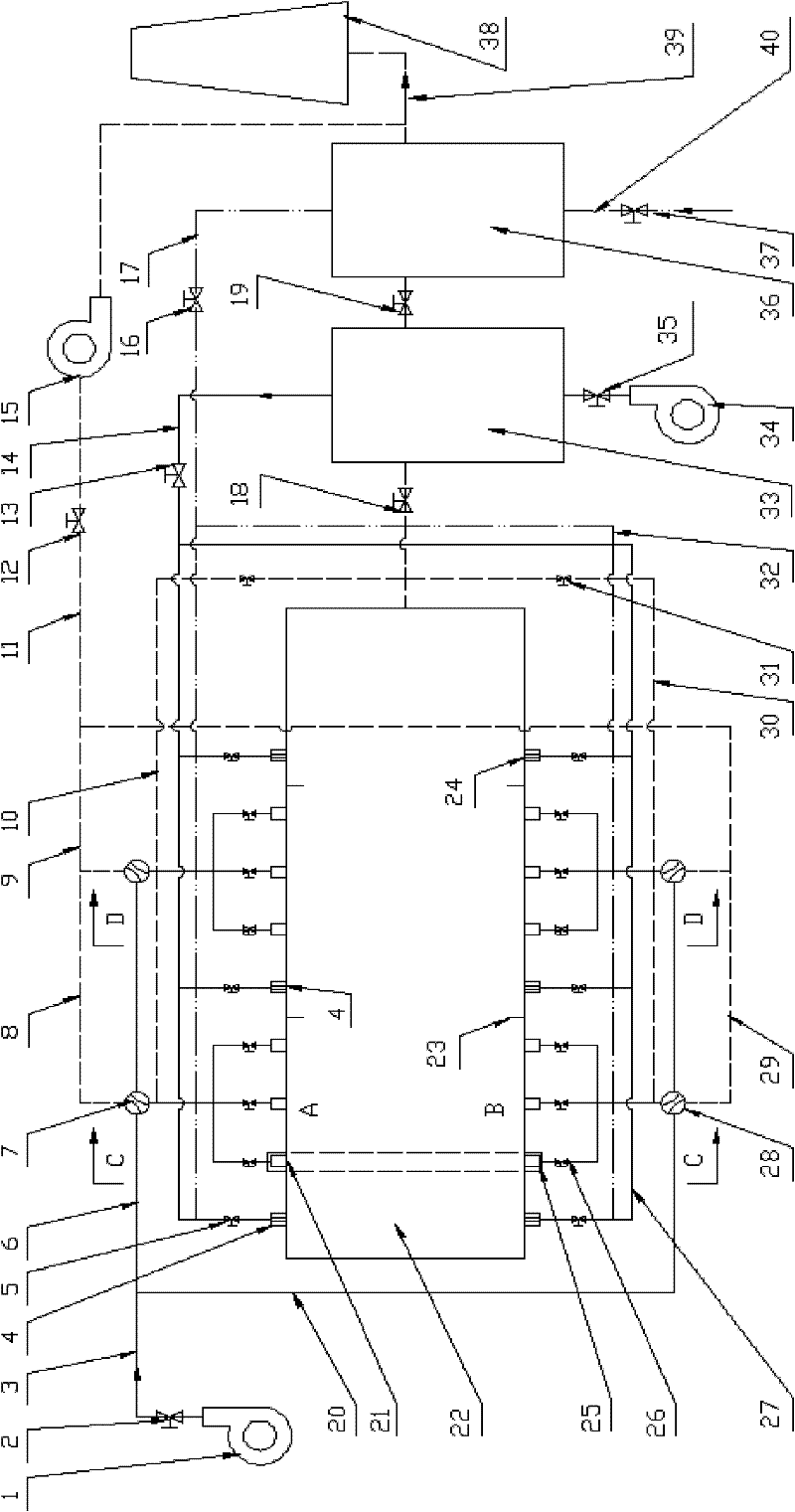

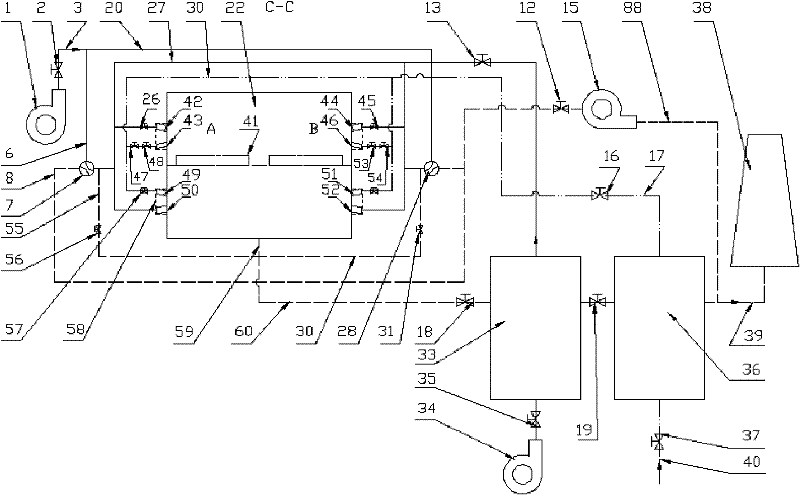

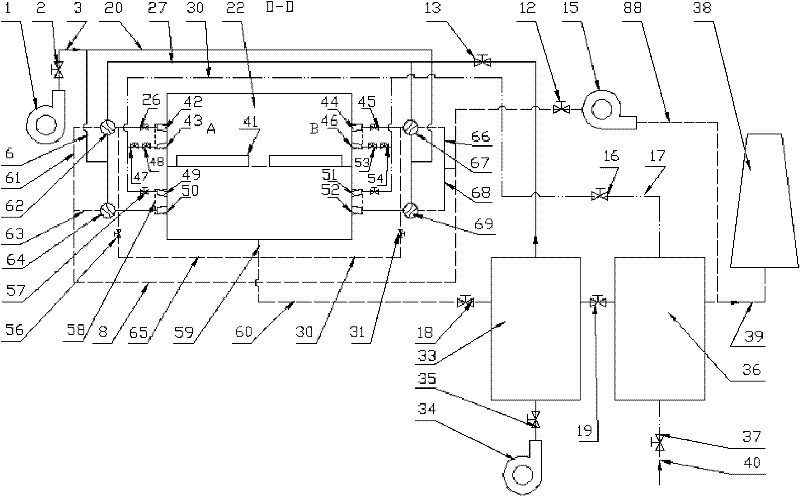

[0069] Such as figure 1 and 6As shown, in the soaking section of the heating furnace 22, taking a reversing cycle, the side A of the heat storage system burns and the side B exhausts smoke as an example. The valve 2 enters the combustion air main pipe 3 of the heat storage system and is divided into two routes, each of which is divided into upper and lower streams, wherein the upper stream of combustion air passes through the combustion air branch pipe 6 on the A side of the heat storage system, and passes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com