Method for preparing lactic acid and ethanol by fermentation of furfural residues

A furfural residue and furfural technology, applied in the field of preparing lactic acid and ethanol, can solve the problems of biomass conversion and fermentation nutrient waste, reducing system efficiency and economy, low lactic acid concentration and difficulty in economical recycling, etc., and achieve high cellulose utilization and Production efficiency, low price, and the effect of speeding up recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

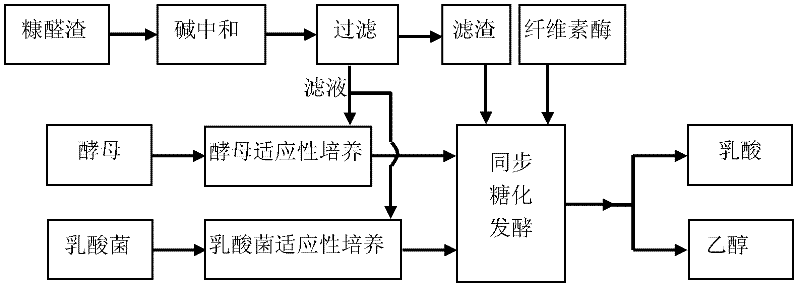

Method used

Image

Examples

Embodiment 1

[0029] 1) 100L aqueous solution of furfural slag (the mass ratio of furfural slag and water is 1: 10) is neutralized with solid NaOH until the pH value of the aqueous solution of furfural slag is 5, then the neutralized aqueous solution of furfural slag is centrifugally filtered to obtain Furfural residue neutralizes filtrate and furfural filter residue.

[0030] 2) Add 7.5g of KH to the 15L furfural slag obtained in step 1) and neutralize the filtrate 2 PO 4 , 7.5g MgSO 4 ·7H 2 O, 1kg yeast, under the culture condition of pH value 4.5, culture temperature 30 ℃, adaptive culture 24h, get the yeast strain.

[0031] At the same time, add 7.5g of KH to the 15L furfural slag obtained in step 1) and neutralize the filtrate 2 PO 4 , 7.5g MgSO 4 ·7H 2 O, 1.5g NaCl, 300g CaCO 3 , 1kg of thermophilic lactic acid bacteria was adaptively cultured for 36 hours under the culture conditions of pH 6.0 and culture temperature 32° C. to obtain lactic acid bacteria strains.

[0032] 3) T...

Embodiment 2

[0037] 1) 100L aqueous solution of furfural slag (the mass ratio of furfural slag and water is 1: 10) is neutralized with solid NaOH until the pH value of the aqueous solution of furfural slag is 5, then the neutralized aqueous solution of furfural slag is centrifugally filtered to obtain Furfural residue neutralizes filtrate and furfural filter residue.

[0038] 2) Add 7.5g of KH to the 15L furfural slag obtained in step 1) and neutralize the filtrate 2 PO 4 , 7.5g MgSO 4 ·7H 2 O, 1kg yeast, under the culture condition of pH value 4.5, culture temperature 30 ℃, adaptive culture 24h, get the yeast strain.

[0039] At the same time, add 7.5g of KH to the 15L furfural slag obtained in step 1) and neutralize the filtrate 2 PO 4 , 7.5g MgSO 4 ·7H 2 O, 1.5g NaCl, 300g CaCO 3 , 1kg of thermophilic lactic acid bacteria was adaptively cultured for 36 hours under the culture conditions of pH 6.0 and culture temperature 32° C. to obtain lactic acid bacteria strains.

[0040] 3)...

Embodiment 3

[0046] Under the same steps and conditions, the furfural filter residues with absolute dry weight of 5%, 7% and 9% were used for fermentation, and the specific steps were as follows:

[0047] 1) 100L aqueous solution of furfural slag (the mass ratio of furfural slag and water is 1: 10) is neutralized with solid NaOH until the pH value of the aqueous solution of furfural slag is 5, then the neutralized aqueous solution of furfural slag is centrifugally filtered to obtain Furfural residue neutralizes filtrate and furfural filter residue.

[0048] 2) Add 7.5g of KH to the 15L furfural slag obtained in step 1) and neutralize the filtrate 2 PO 4 , 7.5g MgSO 4 ·7H 2 O, 1kg yeast, under the culture condition of pH value 4.5, culture temperature 30 ℃, adaptive culture 24h, get the yeast strain.

[0049] At the same time, add 7.5g of KH to the 15L furfural slag obtained in step 1) and neutralize the filtrate 2 PO 4 , 7.5g MgSO 4 ·7H 2 O, 1.5g NaCl, 300g CaCO 3 , 1kg of thermop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com