Method for preparing functional building ceramic

A technology of architectural ceramics and functional ceramics, applied in the field of architectural ceramic materials, can solve the problems of high cost, unacceptable, and expensive functional architectural ceramics, and achieve the effects of low cost, stable performance, and strong economic applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The present invention is a preparation method of functional architectural ceramics, which adopts a two-stage mixing process to coat a layer of functional ceramic material on the surface of ceramic blank particles, and then press molding and firing to obtain a three-dimensional network structure phase and a ceramic filler phase. Composed of functional architectural ceramics. The two-stage mixing process is to add the functional ceramic powder to the ceramic blank according to a certain proportion, put it in the mixer for mixing, and then carry out homogenization treatment through multi-layer equal-diameter sieve holes, so that the functional ceramic powder can be evenly coated on the ceramic Billet particle surface. Among them, functional ceramic powders include photocatalytic ceramic powders, self-cleaning ceramic powders, high toughness ceramic powders and ceramic fiber reinforced materials, high thermal conductivity ceramic materials, magnetic ceramic materials and hi...

Embodiment 1

[0027] Preparation process of photocatalytic sterilizing tiles:

[0028] 1. Preparation of composite ceramic powder with photocatalytic function: 20% modified anatase nano-titanium dioxide, Al 2 o 3 16%, SiO 2 50%, CaO2.5%, MgO3.5%, K 2 O1.8%, Na 2 O2.2%, ZnO1.6% and BaO2.4% are mixed and ball milled, dried, granulated, and passed through a 100-mesh sieve to obtain the required photocatalytic composite ceramic powder;

[0029] 2. Weigh the photocatalytic functional composite ceramic powder and the ceramic blank according to the mass ratio of 10:90, put them in a vertical mixer for mixing, and then pass through 6 layers of 30-mesh mesh sieves for homogenization treatment. The surface of ceramic blank particles is evenly coated with a layer of photocatalytic functional composite ceramic powder;

[0030] 3. Compress the mixed powder obtained in step 2 into a kiln for firing. The firing temperature is 1180° C. and the firing time is 55 minutes.

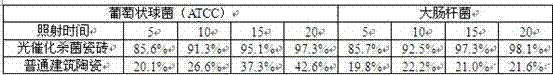

[0031] The photocatalytic st...

Embodiment 2

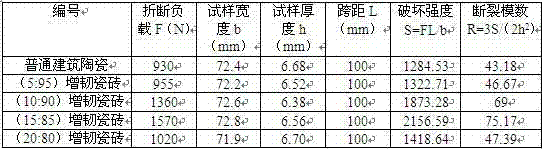

[0035] Preparation process of chopped fiber toughness reinforced tiles:

[0036] 1. Preparation of ceramic chopped fiber composite ceramic powder: mix (by weight percentage) high-temperature aluminum silicate chopped fiber 25%, Al 2 o 3 18%, SiO 2 46%, CaO2.0%, MgO2.0%, K 2 O1.8%, Na 2 O3.2%, ZnO1.0% and BaO0.5% are mixed and ball milled, dried, granulated, and passed through a 100-mesh sieve to obtain the required conductive powder;

[0037] 2. Weigh the ceramic chopped fiber composite ceramic powder and the ceramic blank according to the mass ratio of 5:95, 10:90, 15:85 and 20:80, respectively, and place them in a vertical mixer for mixing. After 6 layers of 30-mesh sieve homogenization treatment, a layer of ceramic chopped fiber composite ceramic powder is uniformly coated on the surface of ceramic blank particles;

[0038] 3. Compress the mixed powder obtained in step 2 into a kiln for firing. The firing temperature is 1235° C. and the firing time is 60 minutes.

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com