Process for separating calcium and magnesium ions from waste water containing manganese

A process method, magnesium ion technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Simple process, small footprint and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

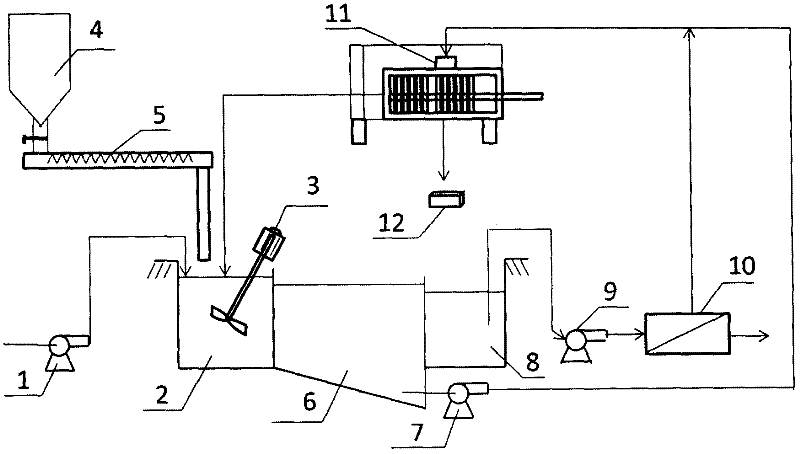

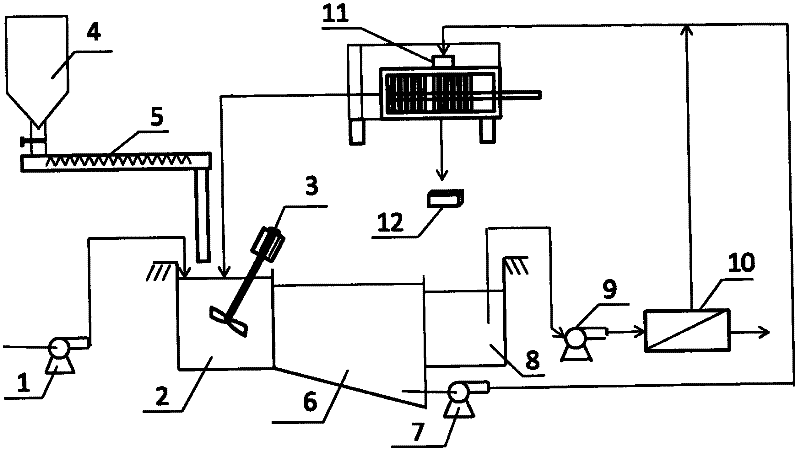

Image

Examples

Embodiment 1

[0026] Example 1: Manganese-containing wastewater 10L / h, pH value is 6.8, initial concentration of water sample: Mn 2+ Concentration 4020mg / m 3 , Ca 2+ Concentration 360mg / m 3 , Mg 2+ The concentration is 2020mg / m 3 . The NaF dosage coefficient is 1.05, the reaction time is 1h, and the precipitation residence time is 1h. Under the above conditions, Ca 2+ 100% removal rate, Mg 2+ The removal rate is 100%.

Embodiment 2

[0027] Example 2: Manganese-containing wastewater 10L / h, pH value is 8.5, initial concentration of water sample: Mn 2+ Concentration 4020mg / m 3 , Ca 2+ Concentration 360mg / m 3 , Mg 2+ The concentration is 2020mg / m 3 . The NaF dosage coefficient is 1.0, the reaction time is 1h, and the precipitation residence time is 1h. Under the above conditions, Ca 2+ 100% removal rate, Mg 2+ The removal rate is 99.3%.

Embodiment 3

[0028] Embodiment 3: Manganese-containing wastewater 1m 3 , pH value is 6.8, initial concentration of water sample: Mn 2+ Concentration 4020mg / m 3 , Ca 2+ Concentration 360mg / m 3 , Mg 2+ The concentration is 2020mg / m 3 . The NaF dosage coefficient is 1.05, the reaction time is 1h, and the precipitation residence time is 1h. Under the above conditions, Ca 2+ 100% removal rate, Mg 2+ The removal rate is 99.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com