Red washable timber and preparation method thereof

A water-resistant and red technology, applied in wood treatment, wood processing equipment, wood treatment details, etc., can solve the problems of easy fading or discoloration, lower dyeing rate, dim shade, etc., achieve bright colors, increase adsorption speed, improve The effect of dye uptake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

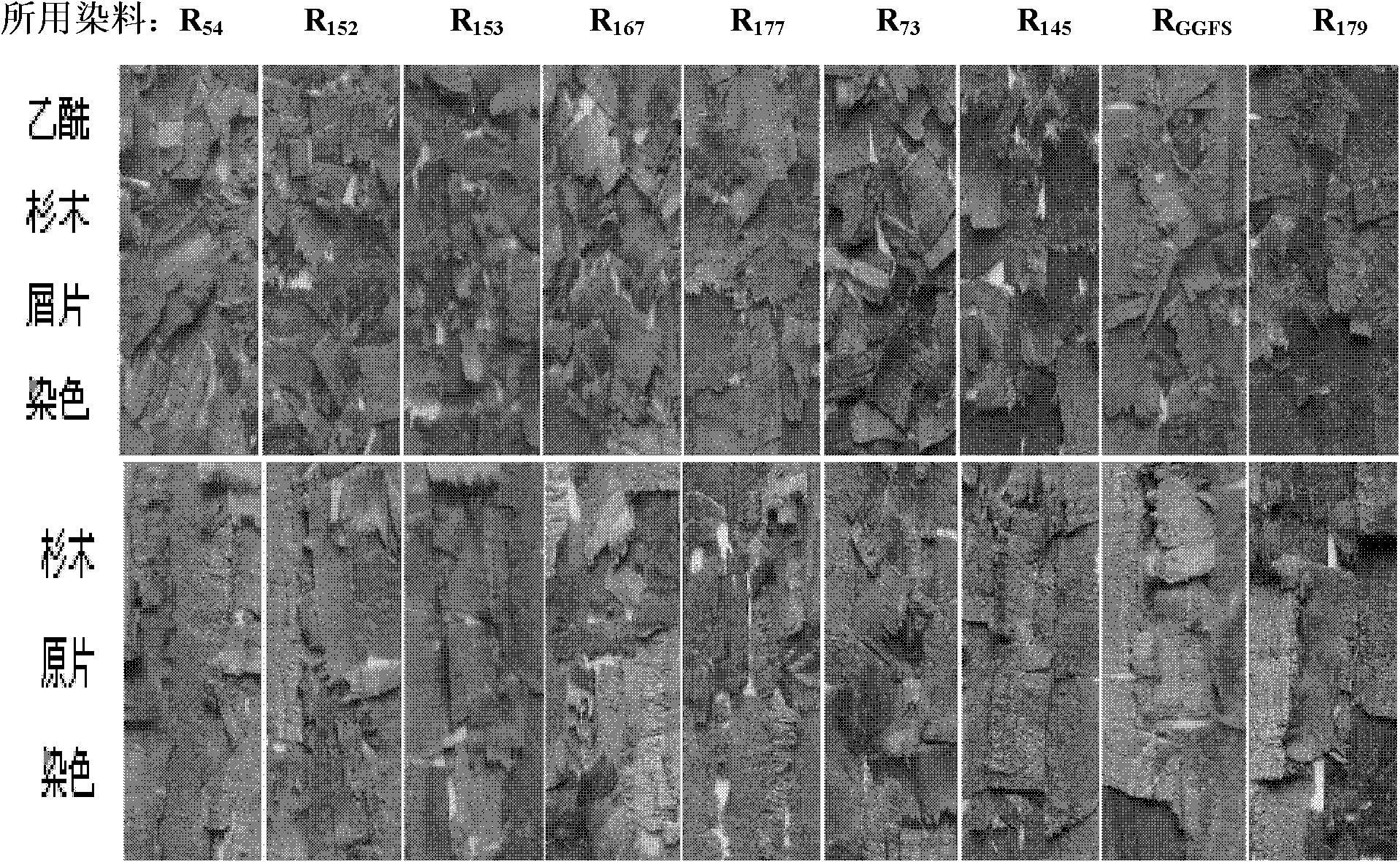

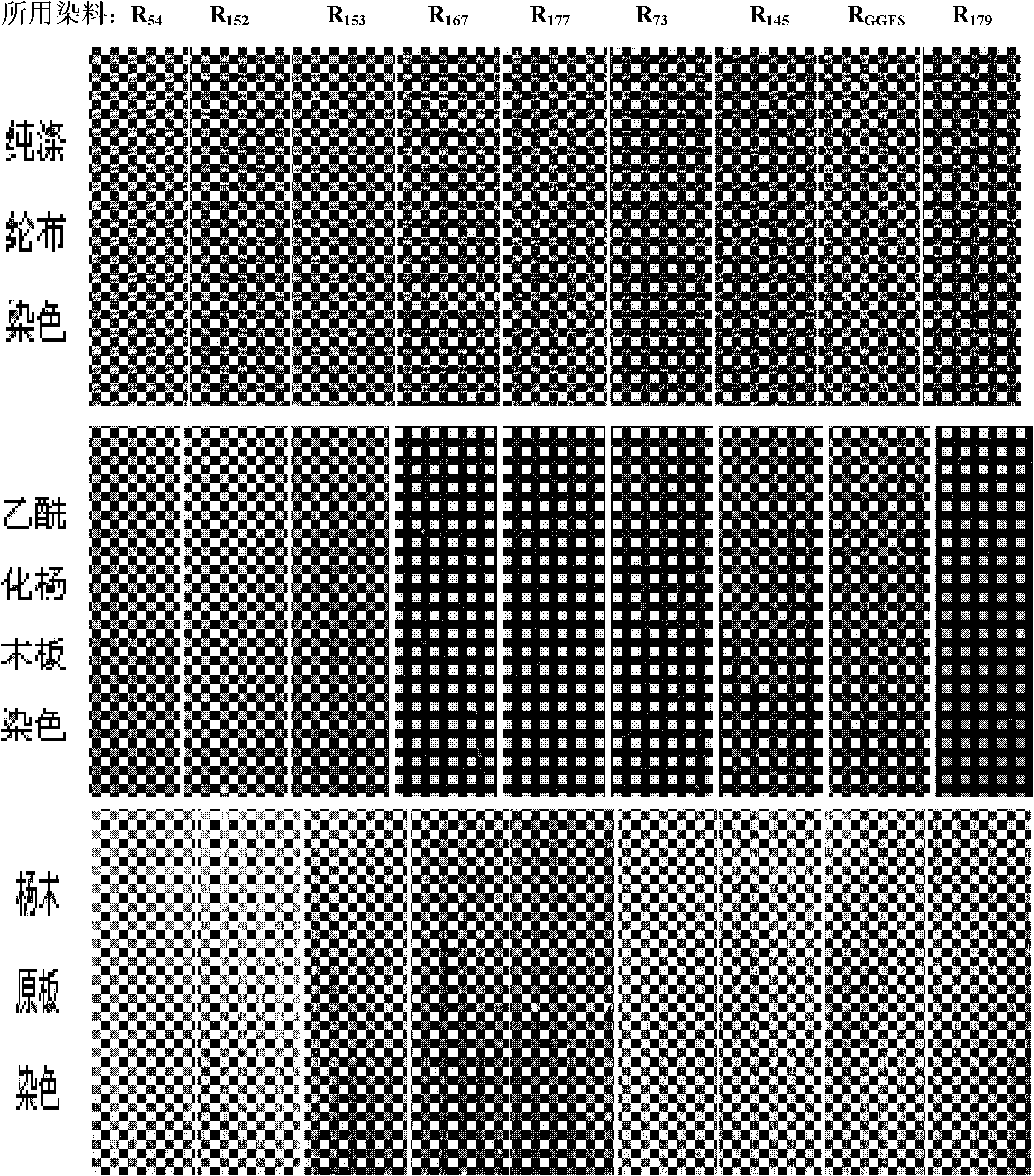

Embodiment 1

[0026] Example 1: In a 250mL three-necked flask equipped with a stirrer, a thermometer and a reflux device, add 20g of Chinese fir powder, 150mL of acetic anhydride, and 30.0g of pyridine, then heat up and react at about 120°C for 1h to 10h. After cooling, the solvent was recovered by suction filtration, washed twice with cold water and once with 95% ethanol, and dried at room temperature to obtain acetylated fir powder.

[0027] Add 200 mL of water, 10.0 g of acetylated fir powder with a weight gain of 15.6%, 0.08 g of 200% Disperse Red 145, 1.0 mL of HAc-NaAc buffer solution, and a pH value of about 4.9 into a stainless steel staining cup, then tighten the staining cup and place In the high temperature and high pressure dyeing machine. Starting from room temperature, the temperature was raised to 100°C at 2°C / min, kept for 60 minutes, and cooled to 60°C at 2°C / min. Take out the staining cup, pour the wood powder in the cup into the Buchner funnel, filter it with suction, ri...

Embodiment 2

[0028] Embodiment 2: According to embodiment 1, add 200mL water in stainless steel dyeing cup, 10.0g the acetylated modified Chinese fir powder of weight gain 5.5%, 0.08g 200% Disperse Red 153 replaces 200% Disperse Red 145, obtains red acetylation Fir powder. The dye uptake rate is 93.6%, and the color fastness to washing of the dyed acetylated fir powder is grade 4. The red acetylated fir powder can be pressed into red water-resistant wood boards after high-pressure pressing.

Embodiment 3

[0029] Embodiment 3: according to embodiment 1, add 200mL water in the stainless steel staining cup, 10.0g the above-mentioned acetylated modified Chinese fir powder of weight gain 45.2%, 2.0g 200% disperse red 177 replaces 200% disperse red 145, start from room temperature , heat up to 100°C at 2°C / min, hold for 12 minutes, and cool down to 60°C at 2°C / min. A pink acetylated fir powder was obtained. The dye uptake rate is 54.2%, and the color fastness to washing of the dyed acetylated fir powder is grade 3. The red acetylated fir powder can be pressed into red water-resistant wood boards after high-pressure pressing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com