Oily fume purification machine

An oil fume purifier and corrugated technology, which are applied in the fields of oil fume removal, chemical instruments and methods, and household heating, can solve the problems of large fluid resistance, difficult to clean, poor air permeability, etc., and achieve low filtration resistance, easy cleaning, and liquid storage. high volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

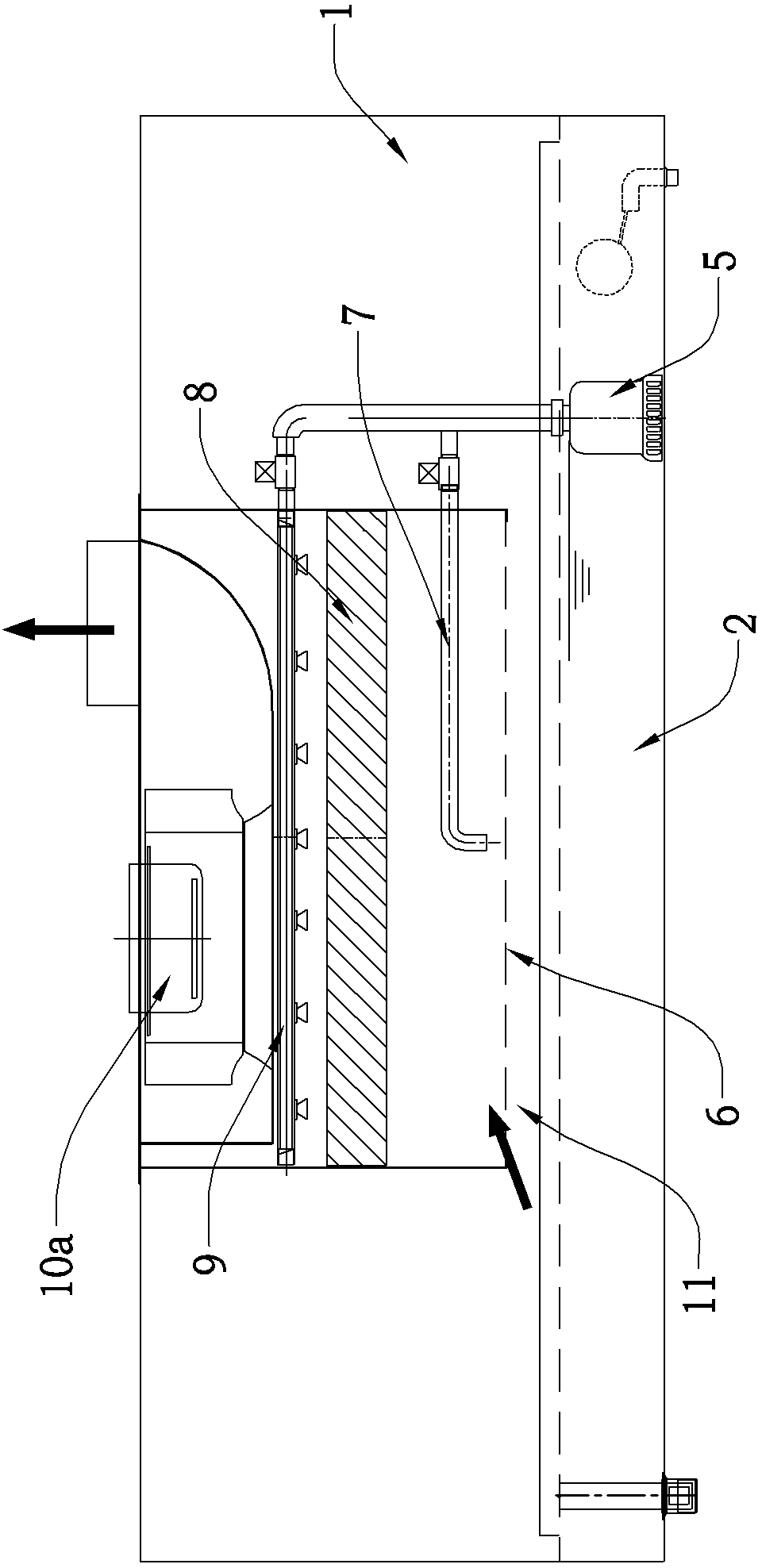

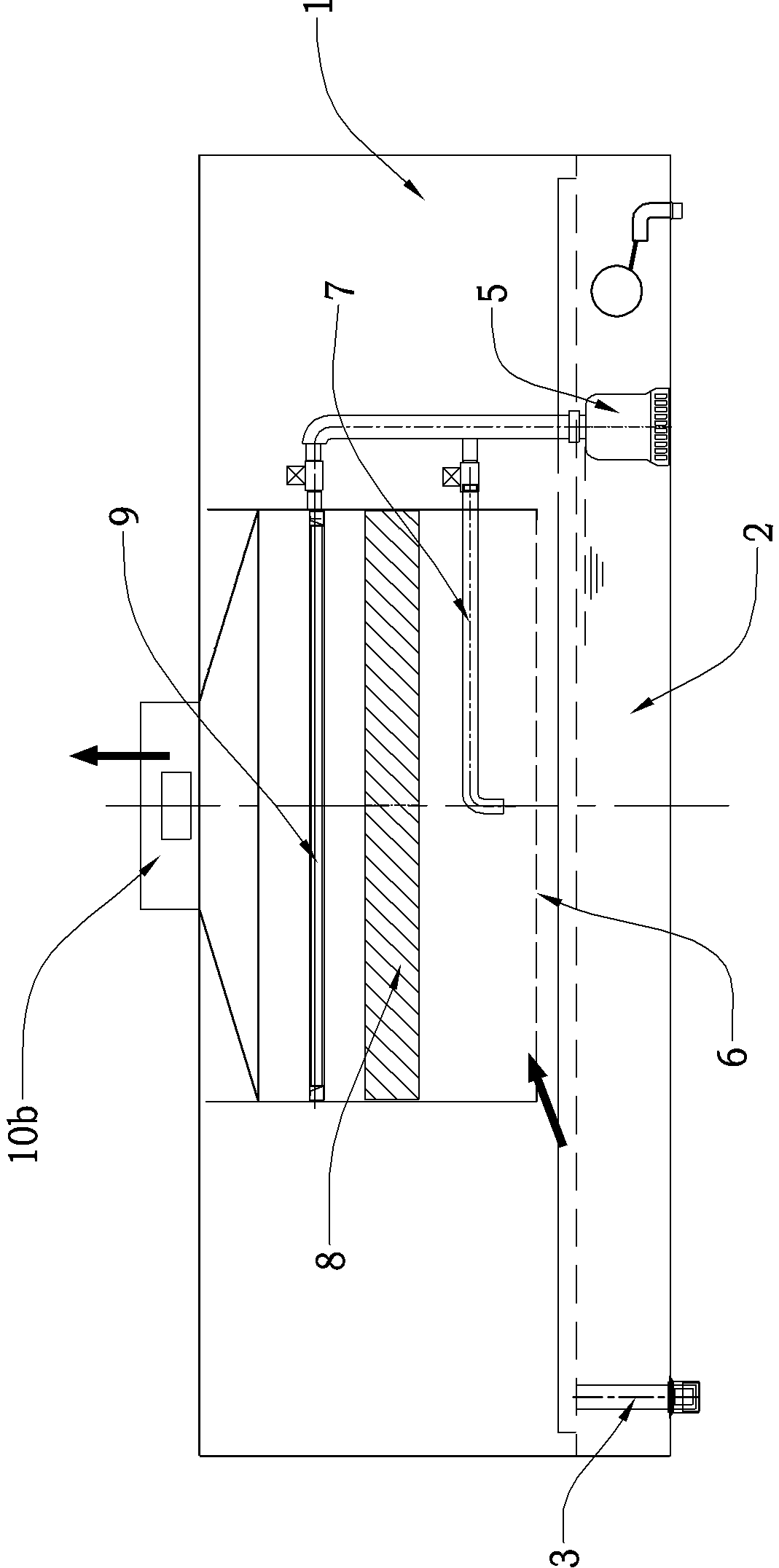

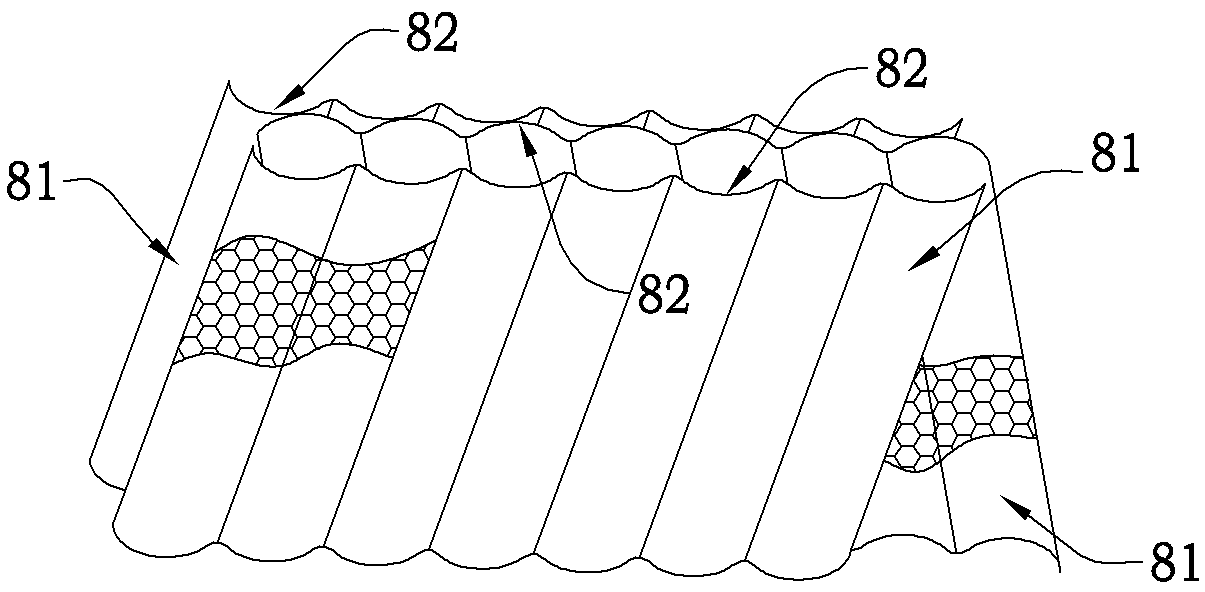

[0011] A lampblack purifier, such as figure 1 , figure 2 , Including a casing 1, the top of the casing as an exhaust fan 10a as an exhaust device, the bottom of the casing is a circulating water tank 2, and an air inlet 11 is opened above the water storage surface of the water tank. A layer of perforated plates is installed in parallel on the upper part of the air inlet to form the reactor 6. The upper part of the reactor is equipped with a liquid inlet pipe 7 which directs water to the top of the reactor, and a gas-liquid separator 8 is arranged above the liquid inlet pipe. The gas-liquid separator, such as image 3 , Figure 4 , Including a plurality of vertically arranged corrugated mesh plates 81, the grooves 82 formed by the corrugations of each corrugated mesh plate are inclined, the grooves of adjacent corrugated mesh plates are staggered, and the gas-liquid separator is also provided above the gas-liquid separator to communicate with the water pump 5. The spray pipe9. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com