Advanced hole-forming method of sand gravel boulder layer

A technology of sand, pebbles and stone layers, which is applied in the field of advance hole forming support, can solve the problems such as the inability to drill advance small conduits, and achieve the effects of light weight, good quality and effect, and fast installation and displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

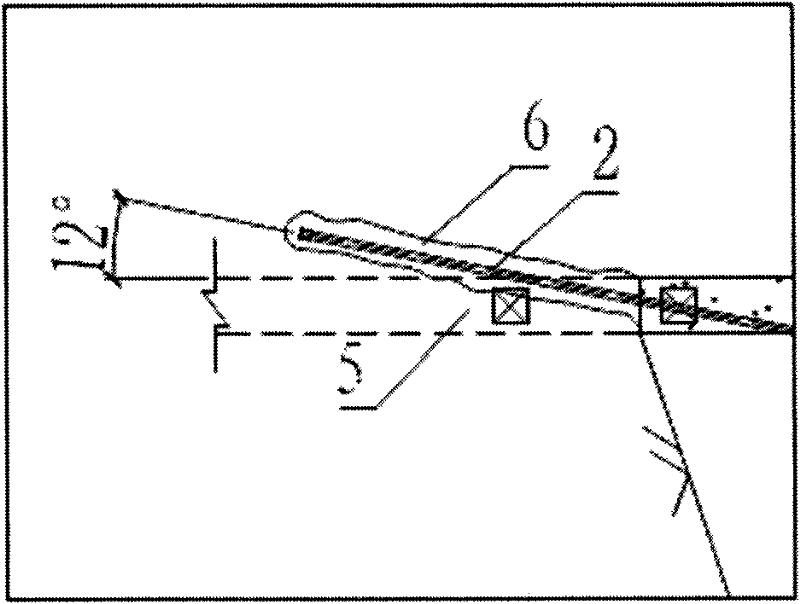

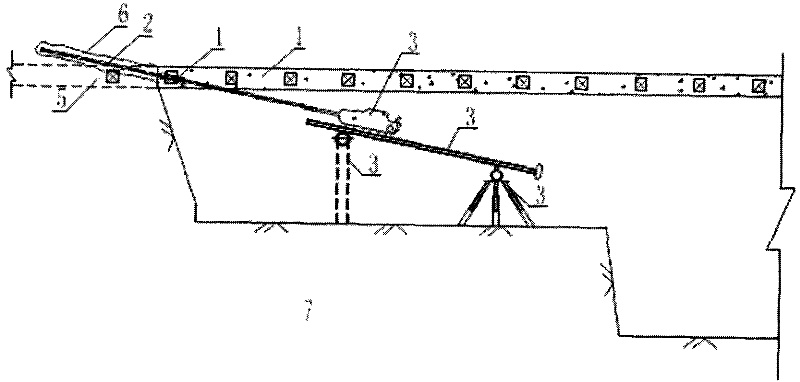

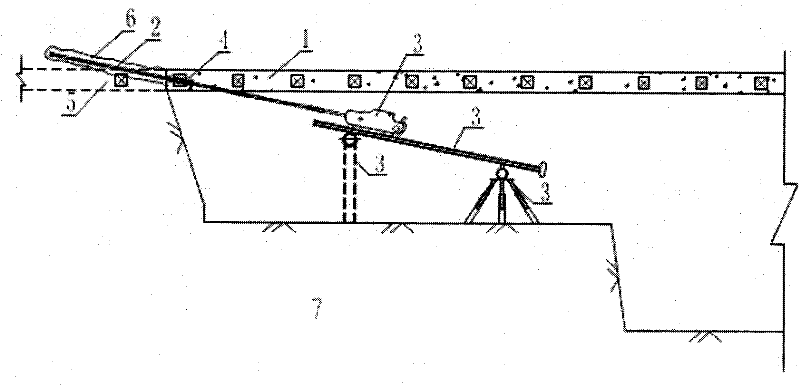

[0020] First of all, the principle of the advanced hole forming method of the guide rail type heavy-duty pneumatic drill combined with the self-propelled hollow grouting bolt in the sand pebble boulder layer of the present invention is introduced in detail.

[0021] The principle is that the guide rail-type heavy-duty pneumatic drill uses the self-propelled hollow grouting anchor rod as the drill pipe, and constructs an advanced small conduit (short steel tube shed) in the sand, pebbles and boulders, that is, using the guide-rail heavy-duty pneumatic drill to drill Insert the self-advancing hollow grouting anchor rod as a small advanced conduit. Due to the characteristics of large impact and brazing torque, the impact energy, brazing speed and torque can be adjusted separately, the drilling speed is fast, and a hole can be formed in about 2 minutes after installation, and it is not easy to jam in the sand and pebble layer. Lightweight, fast installation and displacement, reaso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com