Process liquid feed mechanism

A technology for processing liquids and supply pipes, which is applied in thin material processing, liquid distribution, liquid injection devices, etc. It can solve the problems of time and manpower, problems that are not recorded, and cannot be solved, and achieve the effect of suppressing liquid residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

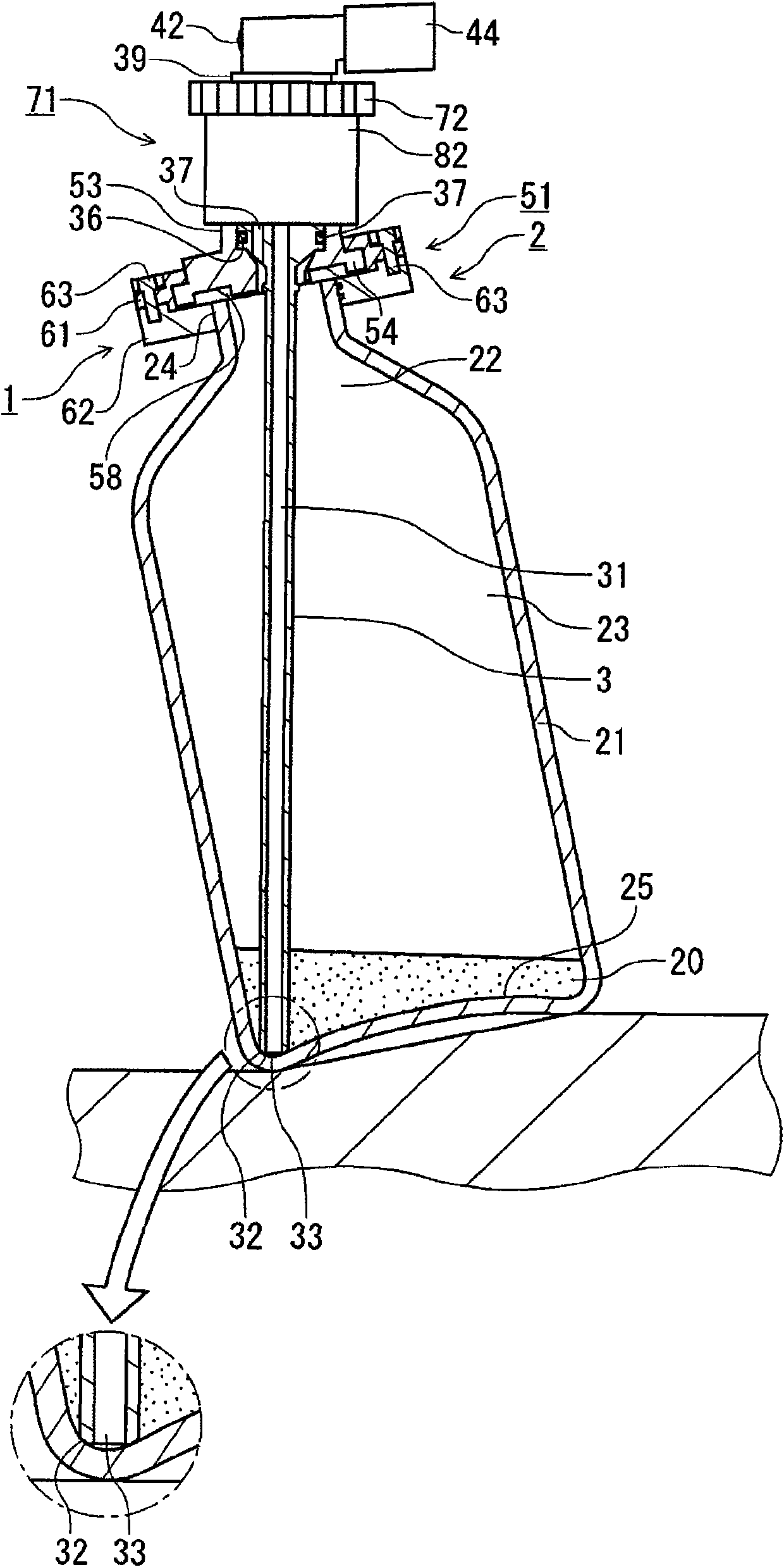

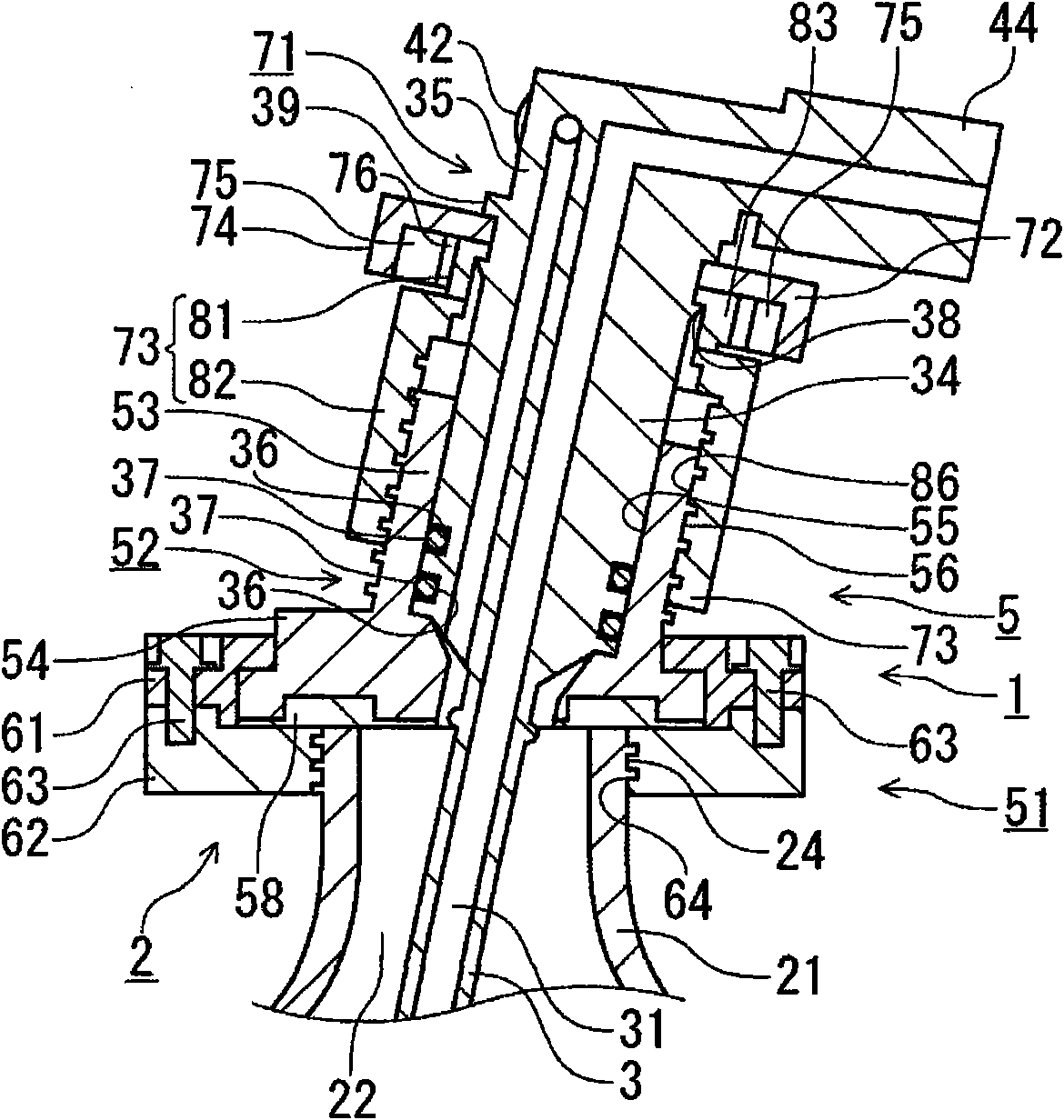

[0035] refer to figure 1 the stereogram and figure 2 The longitudinal cross-sectional side view of the present invention will describe a pressurized resist supply container 2 having a resist supply mechanism 1 as an embodiment of the present invention. The pressurized resist supply container 2 is composed of a resist supply mechanism 1 and a liquid storage bottle 21 as a container body, and the resist supply mechanism 1 is configured to be detachably attached to the liquid storage bottle 21 .

[0036] The resist supply mechanism 1 includes a resist supply pipe 3 and a bottle cap 5 as a processing liquid supply pipe. The liquid storage bottle 21 stores the resist 20 as a processing liquid. The resist supply pipe 3 supplies the above-described resist 20 from the liquid reservoir 21 to the external wafer. The bottle cap 5 has a function of adjusting the height position so that the lower end of the resist supply pipe 3 contacts the bottom of the liquid storage bottle 21 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com