Flying disk engine

An engine and duct technology, applied in aircraft control, aircraft parts, aircraft, etc., can solve problems such as inability to achieve balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

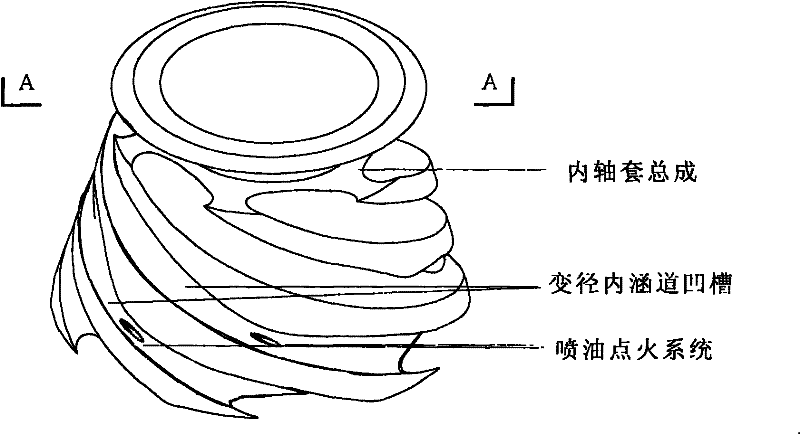

[0014]When the engine is ignited and running, the turbojet engine system is first started. Due to the rotation of the air-gathering turbofan on the top, a large amount of air is pressed into the inner channel, and multiple downward-swirling inner channels and the air-gathering turbofan form the basic structure of the jet engine. Several fuel injection ignition systems inject fuel to ignite, and the engine starts. Since the exhaust direction of the tail turbine is designed to be tangent to the bottom circle of the central shaft sleeve, the flying saucer does not rely entirely on the tail thrust to rise, but spins at high speed. With the increase of fuel injection, the thrust of the bottom turbine increases, and the speed gradually increases. The rotational speed of the turbofan at the top increases year-on-year, so that the compressed air of the air-gathering turbofan also increases, and it rotates faster and faster. A large amount of air is pressed into the exhaust duct from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com