CO2 gas protection flux-cored wire for matching welding of low-alloy steel with strength of 490 MPa

A gas shielded welding and low alloy steel technology, applied in welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of unmatched technical requirements and poor porosity resistance of low alloy steel welded joints with mechanical properties. Enhanced porosity resistance and improved moisture absorption ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

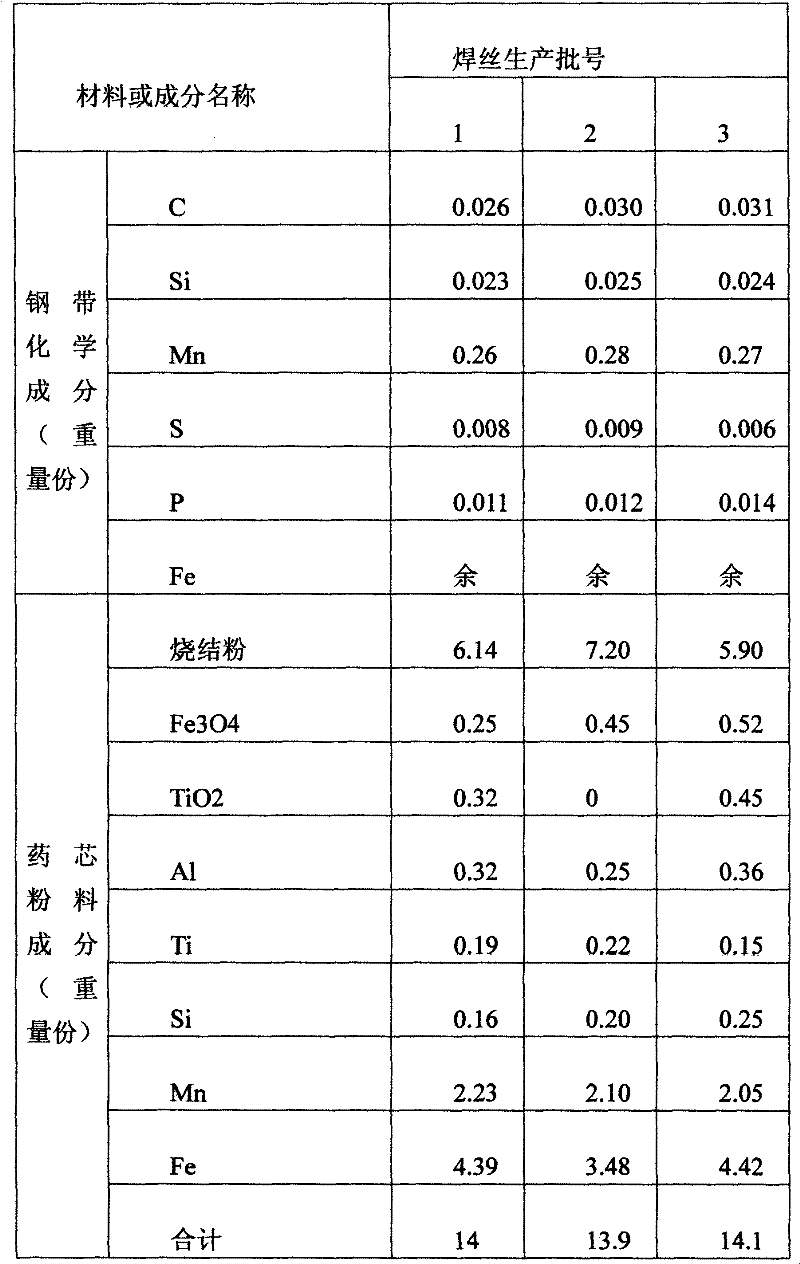

[0010] The strength 490MPa low-alloy steel supporting welding CO used for welding described in the embodiment of the present invention 2 Gas-shielded flux cored welding wire, made of steel strip and flux core powder, the flux core powder includes the following components in parts by weight: sintering powder 4-10, Fe 3 o 4 0.1-0.7, TiO 2 0-1.0, Al 0.1-0.5, Ti 0-0.4, Si 0.1-0.5, Mn 2.0-2.5, Fe 1.0-2.0. The sintered powder is made of the following raw materials in parts by weight: TiO 2 30-80, SiO 2 8-15, MgO 1-7, fluoride 1-7, ZrO 2 1-7, Al 2 o 3 2-10,K 2 O+Na 2 O 0~5. The fluoride is composed of MgF 2 +NaF composition, where MgF 2 Weight≤40%.

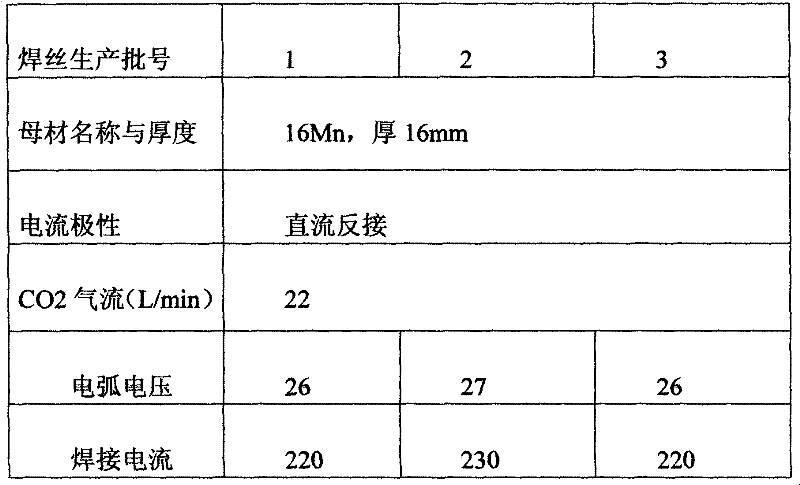

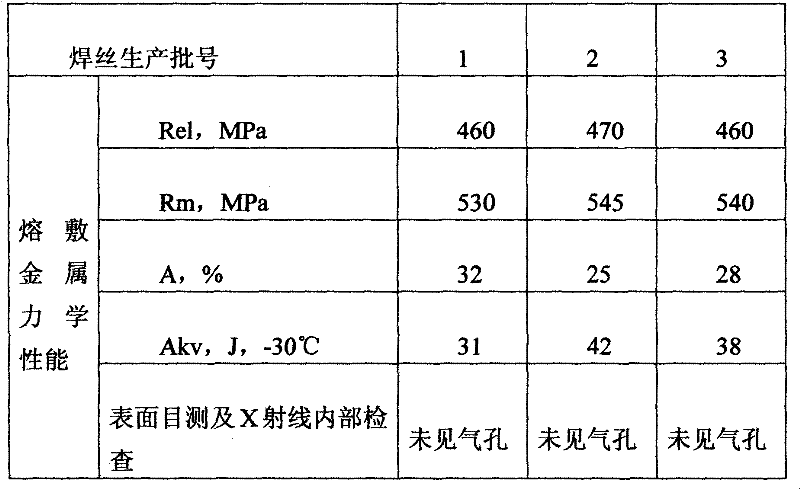

[0011] According to the composition of the core powder of the flux-cored wire of the present invention, three batches of flux-cored wires with the brand name NY490 were produced. The base metal and welding process parameters of the three batches of welding wire are shown in Table 2. After welding, the mechanical prope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com