A Measuring Cell for Optically Addressable Potential Sensors

A potential sensor and measuring cell technology, applied in the field of sensors, can solve problems such as complex design structure, bulky size, and insufficient accuracy, and achieve the effects of simple manufacturing process, high signal strength, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

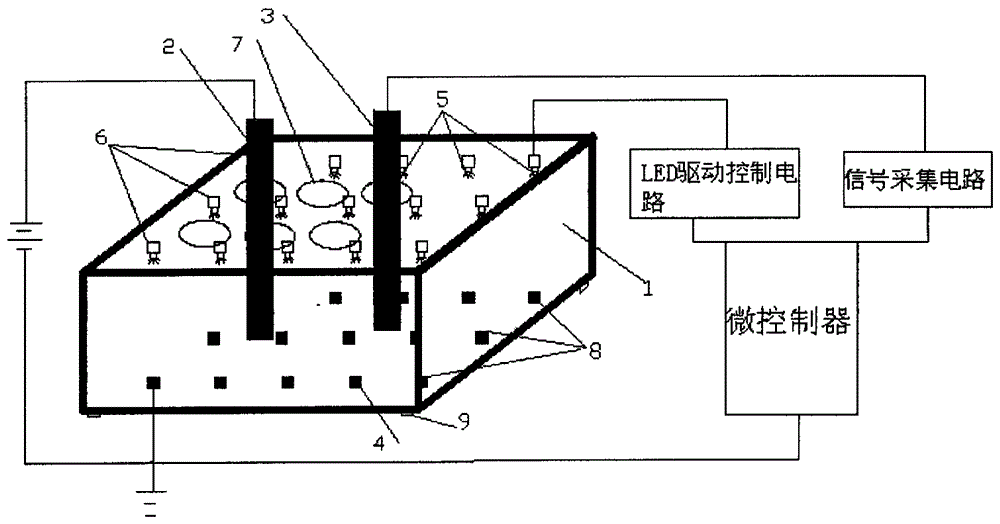

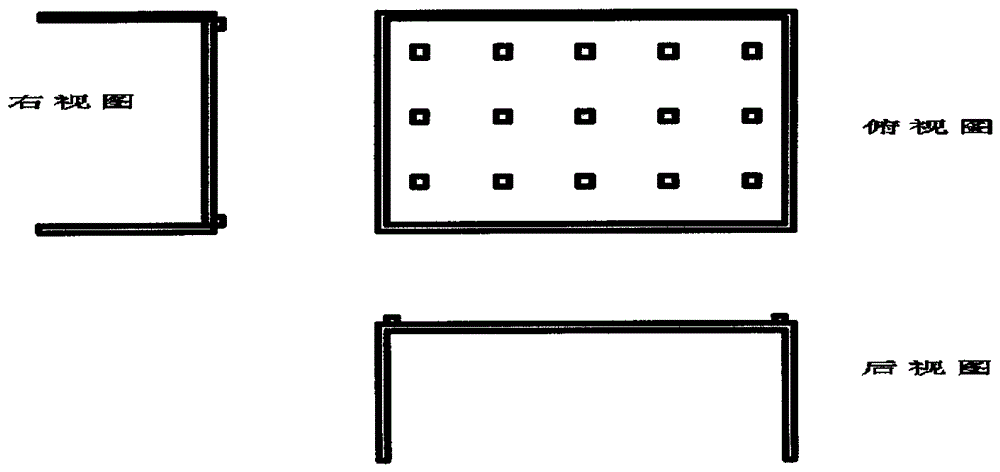

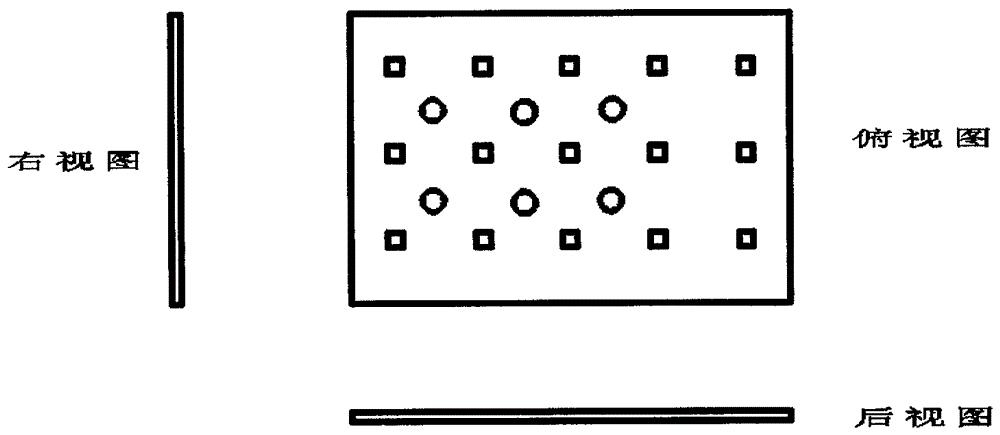

[0013] Embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings. figure 1 It is the structural diagram of the photo-addressable potential sensor, including measuring cell (1), reference electrode (2), measuring electrode (3), silicon wafer coated with sensitive film (4), LED array (5), square array ( 6), circular holes (7), square arrays (8), brackets (9) and other components. The LED array (5) is embedded in the square array (6); the silicon chip (4) of the sensitive film is adhered to the bottom of the square array (8); the reference electrode (2), the measuring electrode (3) are inserted into the circular hole (7), Immersed in the solution to be tested; a bias voltage is applied between the bottom of the silicon chip and the reference electrode (2); the whole optical addressing potential sensor structure is supported by the support (9); the photocurrent is drawn out by the measuring electrode (3). Figure 4 It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com