Composite power system and method for recycling flue gas afterheat of vehicles

A flue gas waste heat and compound power technology, applied in the field of energy and power, can solve the problems of low engine exhaust pressure, affecting engine performance, complex structure, etc., and achieve the effect of increasing the output mechanical energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

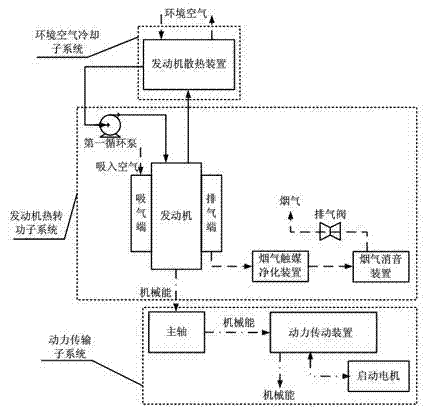

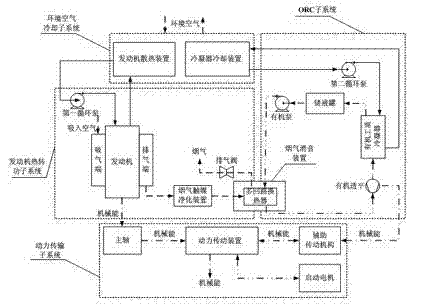

[0018] Refer below figure 1 , figure 2 Describe the operation process of the hybrid power system for recovering waste heat from vehicle flue gas.

[0019] figure 2 It is a vehicle flue gas waste heat recovery composite power system proposed by the present invention. The working process of this system is as follows: start the first circulation pump, and drive the piston engine to start running through the starter motor; The heat energy of the flue gas pushes the piston to move and converts it into the mechanical energy of the crankshaft. After the engine works normally, the starter motor is cut off, and the mechanical energy is sent to the power transmission subsystem. At the same time, the ambient air cooling subsystem that cools the engine cylinder coolant starts; The high-pressure and high-temperature exhaust gas output from the gas end first passes through the catalytic purification device to remove toxic and corrosive components in the flue gas; the high-temperature a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com