New continuous production stabilization and efficient interactive blockage removal method for high water later oil reservoir of oil field

A new method and oil layer technology, applied in chemical instruments and methods, earthwork drilling, production fluids, etc., can solve problems such as high energy consumption, affecting oil field economic benefits, destroying reservoir structure, etc., to achieve enhanced recovery and improved The effect of development and the effect of broad development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

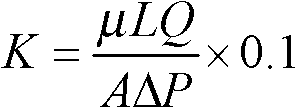

Method used

Image

Examples

Embodiment 2

[0017] Embodiment 2 The application of the present invention method on Zhong 4-103 well of Daqing No. 1 Oil Production Plant: Zhong 4-103 well, put into production in May 1985, oil production well section 1856.4~1936.2m, s layer 25.sm commingled production, each layer interval 0.5 ~ 1m range. After 20 years of water injection development, the water content has increased, and the daily water production before the blockage was 55m 3 , with a daily oil production of 2.7t and a water cut of 95.1%. Before the measures, the cumulative oil production was 52,000 tons and the water production was 1.327 million tons. According to analysis, the well was flooded by a water injection well with high water cut.

[0018] In August 2010, the well was acidified and plugged using the new plugging and unblocking method of the application, as follows: (1) According to the water flooding situation of the well, the design porosity was calculated according to 30%, the treatment radius was 5m, and the...

Embodiment 3

[0020] Example 3 Application of the method of the present invention in Well Bei 54-60: Before the construction of this well, the daily liquid production was 17.5 tons, the oil volume was 0.4 tons, and the water content was 97.8%. Construction began at 8:10 on July 11, 2010. Before construction, an acid-resistant oil-soluble temporary plugging agent was prepared according to the method described in Example 1. The formula of the temporary plugging agent was composed by weight percentage: modified asphalt: 65 %; split cationic asphalt emulsifier: 10%; surfactant: 0.4%; pH regulator: 0.2%; the balance is water.

[0021] Squeeze in temporary plugging agent 10m first 3 , the construction pressure was 5.2Mpa, the site construction was completed at 12:20, the pump stop pressure was 5.6MPa, and the well shut-in response was 1d.

[0022] Construction continued at 12:40 on July 12, and 75m of acidizing and plugging solution was squeezed in 3 , the selected acidification plugging soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com