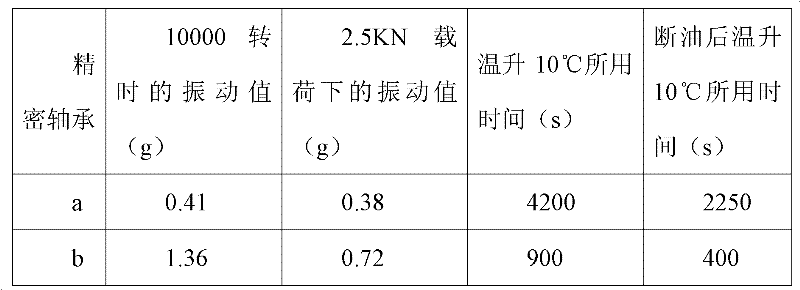

Method for self-lubricating steel balls for precision bearing by ion-plating GLC (graphite-like carbon) coating

A technology of precision bearing and processing method, applied in the field of material manufacturing, to achieve the effects of low vibration amplitude, good stability and slow vibration increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Step 1: Ultrasonic cleaning is performed on the steel balls to be treated. The specific method of ultrasonic cleaning is: put the steel balls to be treated in acetone solution, ultrasonically clean them for 5 minutes, then put them in ethanol, and ultrasonically clean them for 5 minutes. Rinse with deionized water and dry with cold air. This step can basically remove the oil on the surface of the steel ball.

[0046] Step 2: Place the steel ball obtained in step 1 in the workpiece disk in the vacuum chamber of the magnetron sputtering ion plating equipment, and the work disk keeps the main shaft rotating and axially vibrating in the following steps. The rotation speed is 1r / min, and the axial vibration swing of the working disk is ±20mm; chromium targets and pure graphite targets are placed in the vacuum chamber, and the distance between all chromium targets and graphite targets and the steel ball is guaranteed to be 30mm.

[0047] Step 3: Sputter Cleaning

[0048] T...

Embodiment 2

[0062] Step 1: Ultrasonic cleaning is performed on the steel balls to be treated. The specific method of ultrasonic cleaning is: put the steel balls to be treated in acetone solution, ultrasonically clean them for 16 minutes, then put them in ethanol, and ultrasonically clean them for 16 minutes. Rinse with deionized water and dry with cold air.

[0063] Step 2: Place the steel ball obtained in step 1 in the workpiece disk in the vacuum chamber of the magnetron sputtering ion plating equipment, and the work disk keeps the main shaft rotating and axially vibrating in the following steps. The rotation speed is 10r / min, and the axial vibration swing of the working disk is ±90mm; chromium targets and pure graphite targets are placed in the vacuum chamber, and the distance between all chromium targets and graphite targets and the steel ball is guaranteed to be 105mm.

[0064] Step 3: Sputter Cleaning

[0065] The vacuum chamber in step 2 is evacuated so that the vacuum degree of ...

Embodiment 3

[0078] Step 1: Ultrasonic cleaning is performed on the steel balls to be treated. The specific method of ultrasonic cleaning is: put the steel balls to be treated in acetone solution, ultrasonically clean for 30 minutes, then put them in ethanol, and ultrasonically clean for 30 minutes. Rinse with deionized water and dry with cold air.

[0079] Step 2: Place the steel ball obtained in step 1 in the workpiece disk in the vacuum chamber of the magnetron sputtering ion plating equipment, and the work disk keeps the main shaft rotating and axially vibrating in the following steps. The rotation speed is 20r / min, and the axial vibration swing of the working disc is ±200mm; chromium targets and pure graphite targets are placed in the vacuum chamber, and the distance between all chromium targets and graphite targets and the steel balls is guaranteed to be 180mm.

[0080] Step 3: Sputter Cleaning

[0081] The vacuum chamber in step 2 is evacuated so that the vacuum degree of the vacu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com