High-speed iron hydrogen storage electrode alloy and nickel-hydrogen battery anode material

A technology for electrode alloys and nickel-metal hydride batteries, applied in battery electrodes, alkaline battery electrodes, circuits, etc., can solve problems such as poor comprehensive performance, achieve the effects of improving efficiency, reducing production costs, and improving market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of the present invention is:

[0038] According to the molecular formula of the present invention La x Ce y m 1 z Ni a Fe b mn c Al d m 2 e The elements of the raw materials are smelted under the protection of inert gas. When the Fe content is high, it can be prepared by single-roll quick quenching method. After annealing or not, it is powdered. The alloy powder passed through a 200-mesh sieve is used to prepare electrodes. Mix hydrogen storage alloy powder and additive Cu powder at a ratio of 1:3, and cold press at a pressure of about 65MPa The thin discs were used as research electrodes.

[0039] The electrochemical performance testing equipment is a computer-controlled DC-5 battery tester. Activation of the half-cell was performed with a 60mAg -1 Charging for 7 hours, 60mAg -1 Discharge to cut-off potential -0.6V (relative to Hg / HgO reference electrode), cycle 7-10 times. The maximum discharge capacity of the metal hydride electr...

Embodiment 1

[0041] Table 1 Composition, discharge capacity and capacity retention of alloys with different stoichiometric ratios

[0042]

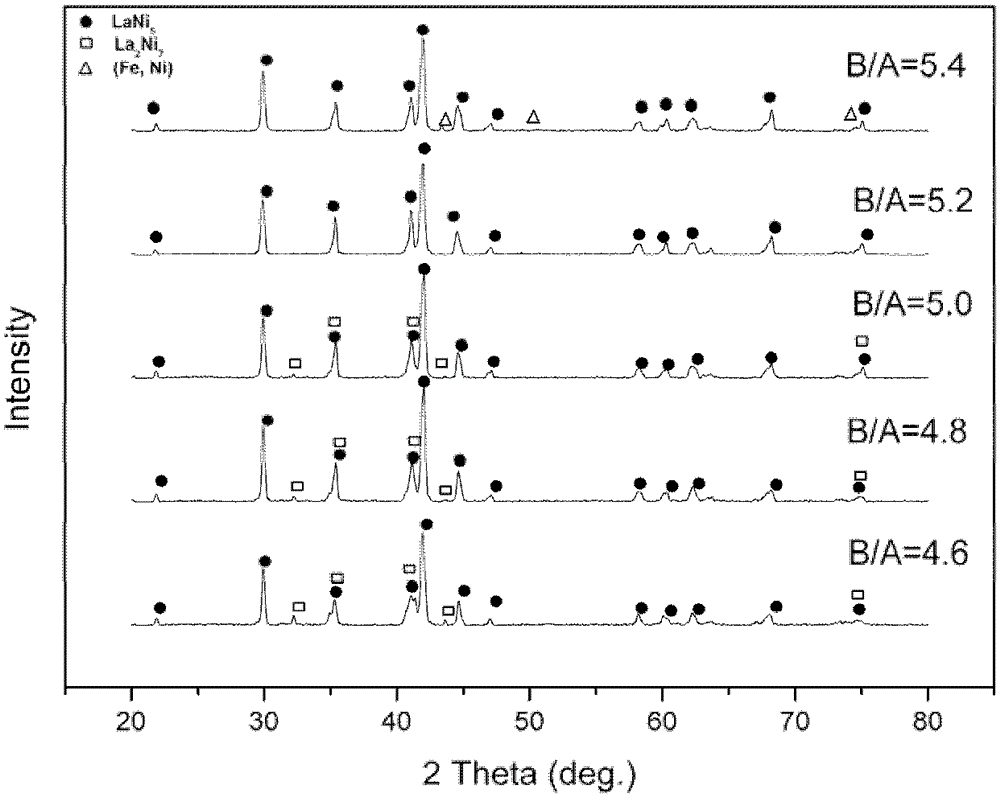

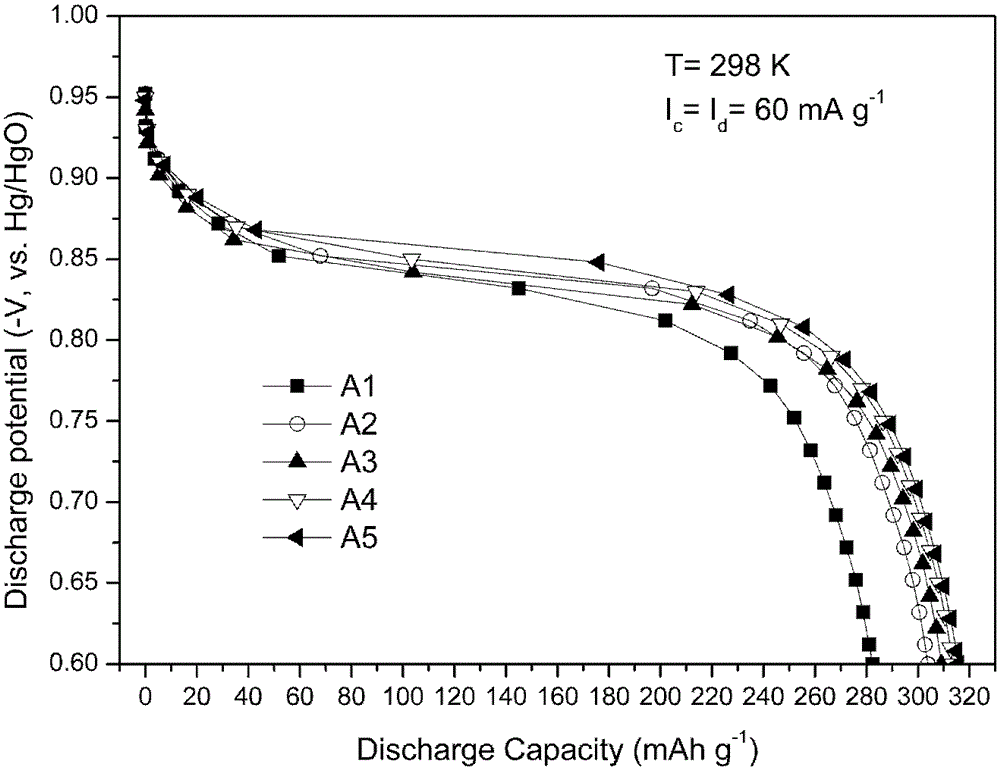

[0043] figure 1 It is the X-ray diffraction spectrum of alloys with different stoichiometric ratios shown in Table 1. It can be seen that under-stoichiometric alloys have a multi-phase structure without annealing, and single-phase structures are easily obtained for over-stoichiometric alloys. At the same time, it can be seen from Table 1 that the discharge capacity and cycle stability of the over-stoichiometric alloy are good, but the selection of the under-stoichiometric alloy is beneficial to further reduce the cost of raw materials. figure 2 is the maximum discharge capacity curve of the five recommended components shown in Table 1, and the maximum discharge capacity of the alloy can reach 315.6mAh / g under the stoichiometric ratio condition.

Embodiment 2

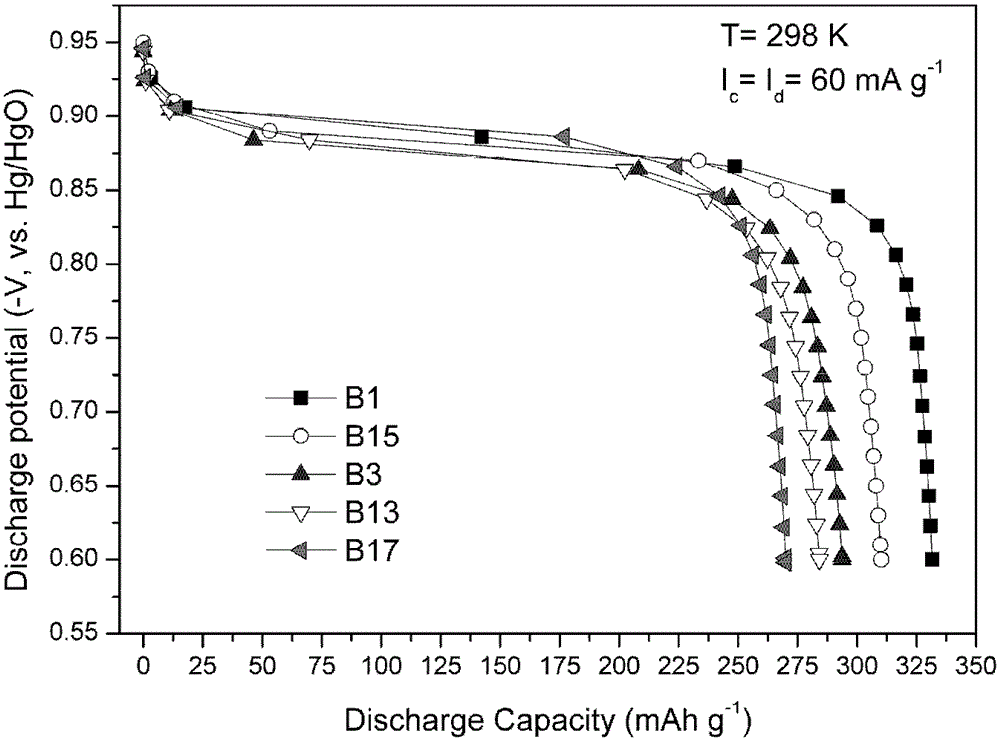

[0045] Table 2 shows the composition, maximum discharge capacity and capacity retention rate of 20 as-cast cobalt-free high-iron LaCe-Ni hydrogen storage electrode alloys. All alloys are made from LaNi 5 Phase single-phase composition. figure 2 is the maximum discharge capacity curve of the five recommended components shown in Table 2, image 3 is the charge-discharge cycle curve of the five recommended components. The maximum capacity of this series of alloys can reach 330mAh / g, and the capacity retention rate can reach more than 90%. It shows that this series of alloys has strong application value.

[0046] Table 2 Composition, discharge capacity and capacity retention of the alloy

[0047] serial number alloy composition 0.2C maximum discharge capacity 150 times capacity protection

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com