Preparation method of heat/ozone/compressive deformation resistant rubber material for automobile sealing element

A rubber material and ozone-resistant technology, which is applied in the field of preparation of heat-resistant, ozone-resistant, pressure-resistant rubber materials for automotive seals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

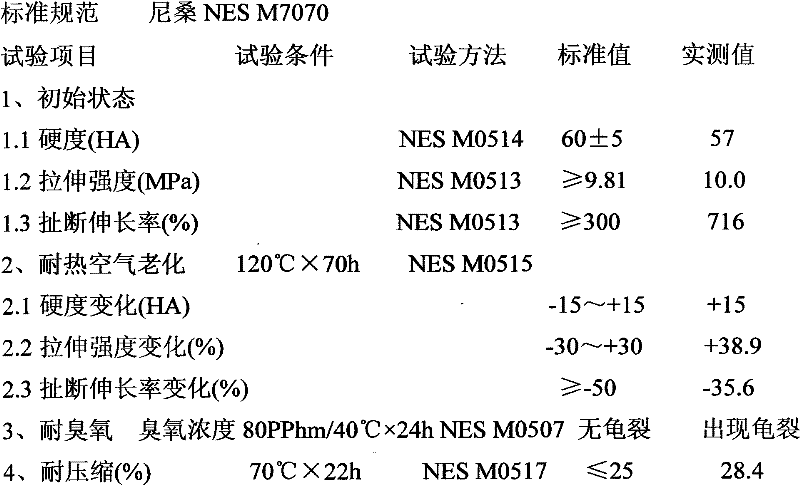

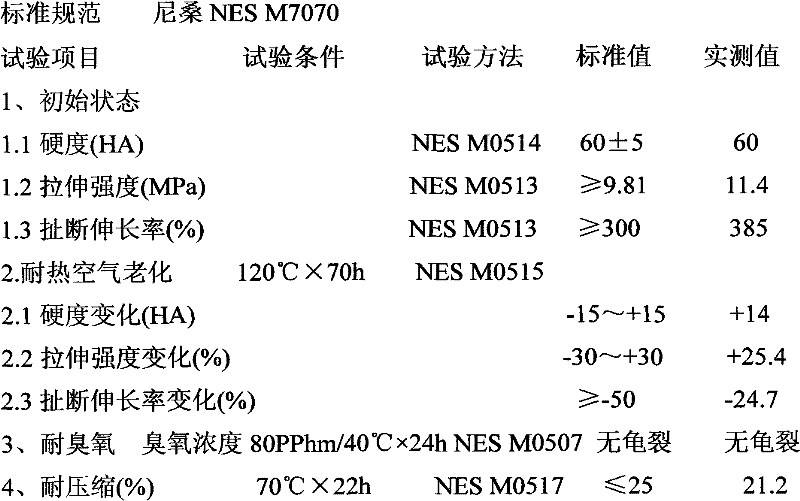

[0027] Product Name: Heat-resistant, ozone-resistant, pressure-resistant rubber material for automotive seals

[0028] Formula: formula unit is percentage by weight;

[0029] Rubber raw material: nitrile / polyvinyl chloride combined rubber (the ratio of nitrile rubber and polyvinyl chloride resin is 85: 15), 43.12%;

[0030] Reinforcing agent: 24.64% of medium-sized thermal cracking carbon black, 6.16% of non-polluting high-definition semi-reinforcing furnace black,

[0031] Plasticizer: Dioctyl phthalate 6.16%, Alkyl ether adipate 6.16%;

[0032] Active agent: zinc oxide, 2.05%; stearic acid, 0.41%;

[0033] Vulcanizing agent: dicumyl peroxide, 1.03%; N, N'-m-phenylene bismaleimide, 0.62%;

[0034] Antiaging agent: 2,2,4-trimethyl-1,2-dihydroquinoline polymer, 0.41%; 2-mercaptobenzimidazole; 0.21%; N-isopropyl-N'-phenyl-p-phenyl Diamine, 0.62%;

[0035] Lubricant: Paraffin 0.20%;

[0036] Filler: light calcium carbonate 8.21%;

[0037] preparation:

[0038] Preparation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com