Wide magnesium alloy ultra-thin plate continuous extrusion device and method

A magnesium alloy, extrusion device technology, applied in metal rolling, metal extrusion dies, other manufacturing equipment/tools, etc., can solve the problems of poor room temperature plasticity, low extrusion cost, high efficiency, and achieve lower production costs, The effect of saving energy and simplifying the extrusion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0037] The invention provides a continuous extrusion and rolling device for ultra-thin wide-width magnesium alloy plates, which includes an extrusion device, a continuous rolling device and a leveling device, and the continuous rolling device is located between the extrusion device and the leveling device.

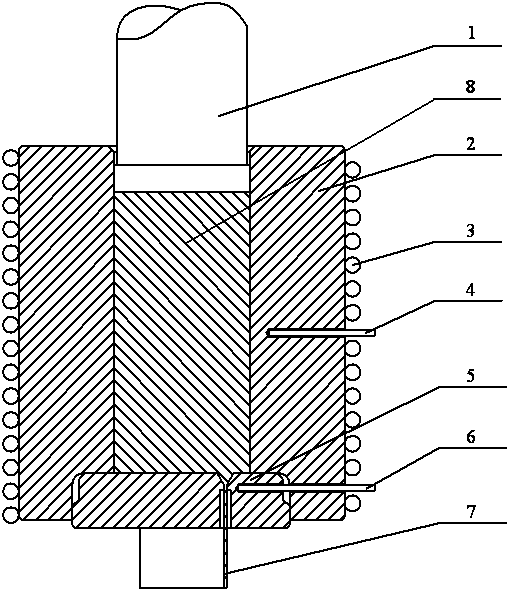

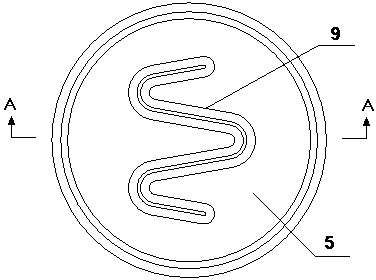

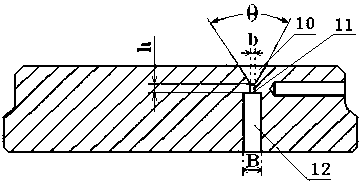

[0038] Such as figure 1 As shown, the extrusion device includes an extrusion barrel 2 and a "W"-shaped extrusion die 5 arranged at the bottom of the extrusion barrel 2. The inner wall of the extrusion barrel 2 and the "W"-shaped extrusion die 5 constitute a die cavity. It is used to place the magnesium alloy blank 8 to be extruded. Such as figure 2 As shown, the "W" type extrusion die 5 is provided with a "W" type gap 9, such as image 3 As shown, the "W" type gap 9 is composed of a flaring 10, an extrusion slit 11 and a discharge por...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com