Tundish with electromagnetic heating water gaps

An electromagnetic heating device and heating water technology, applied in the field of tundish, can solve the problems of poor temperature independent control ability, low heating efficiency of tundish, lower superheat of molten steel, etc., achieve high controllability, high heating efficiency, improve Effect of strand quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

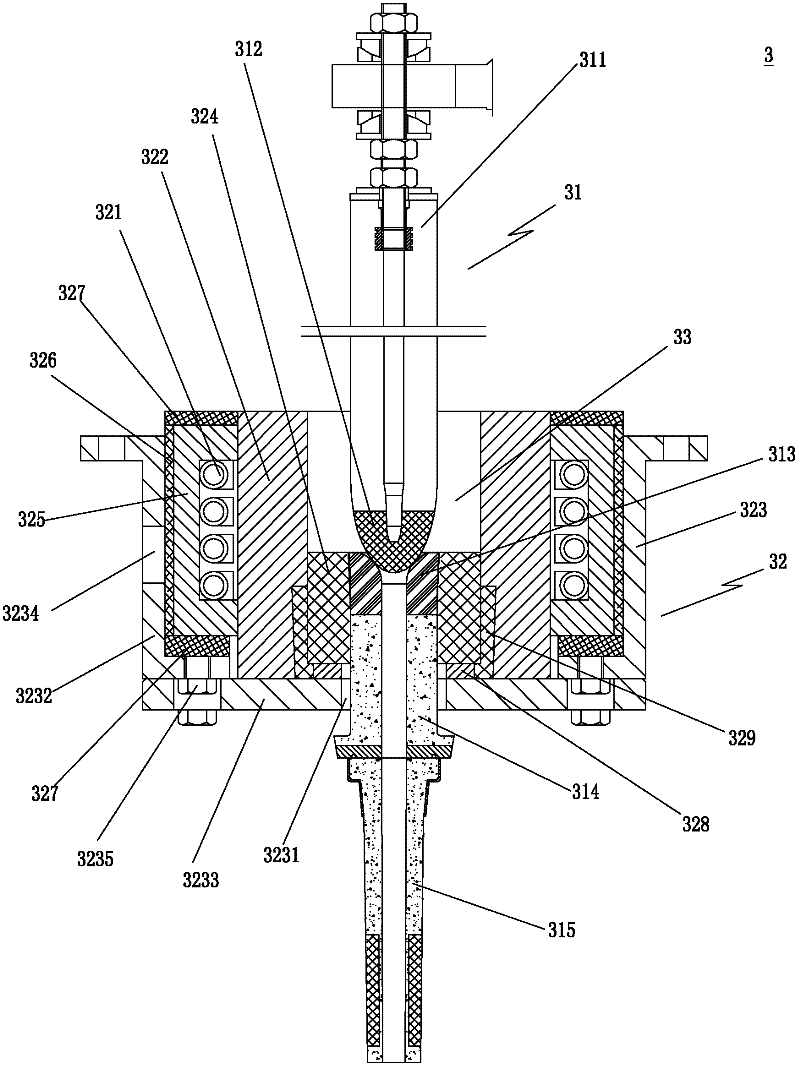

[0037] Such as figure 1 As shown, the present invention proposes an electromagnetic heating nozzle 3, the electromagnetic heating nozzle 3 is composed of a plug rod type nozzle 31 and an electromagnetic heating device 32 which is arranged on the outside of the plug rod type nozzle 31, the inner wall of the electromagnetic heating device 32 and the An annular cavity 33 is formed between the stopper rods 311 of the stopper nozzle 31 to form an annular melting pool heated by electromagnetic induction. The junction of shaped brick 313.

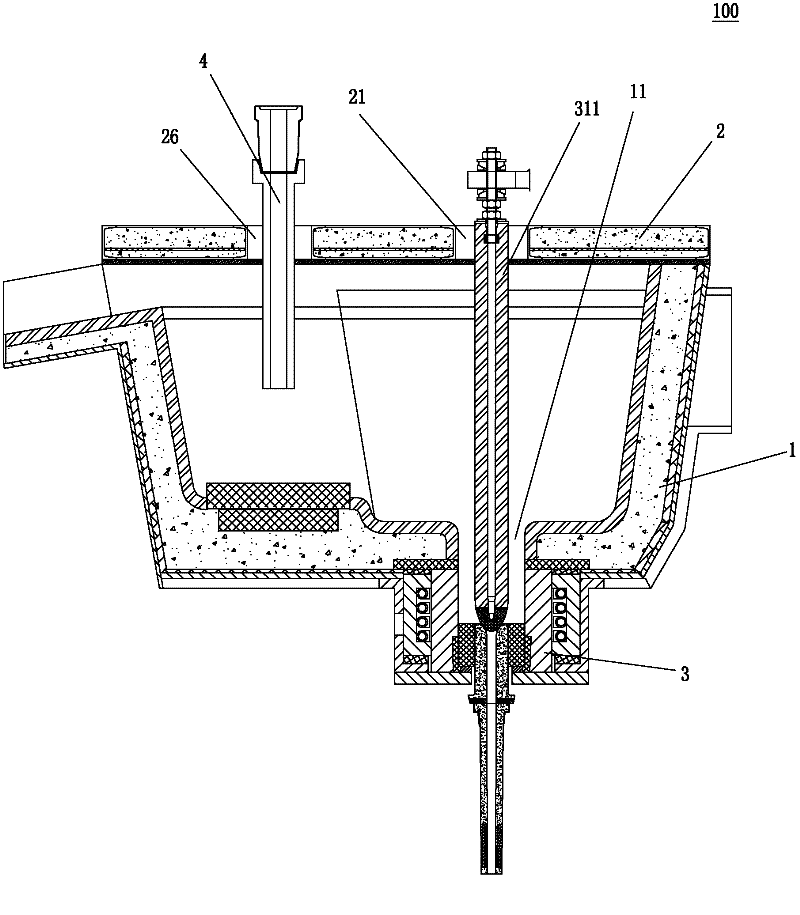

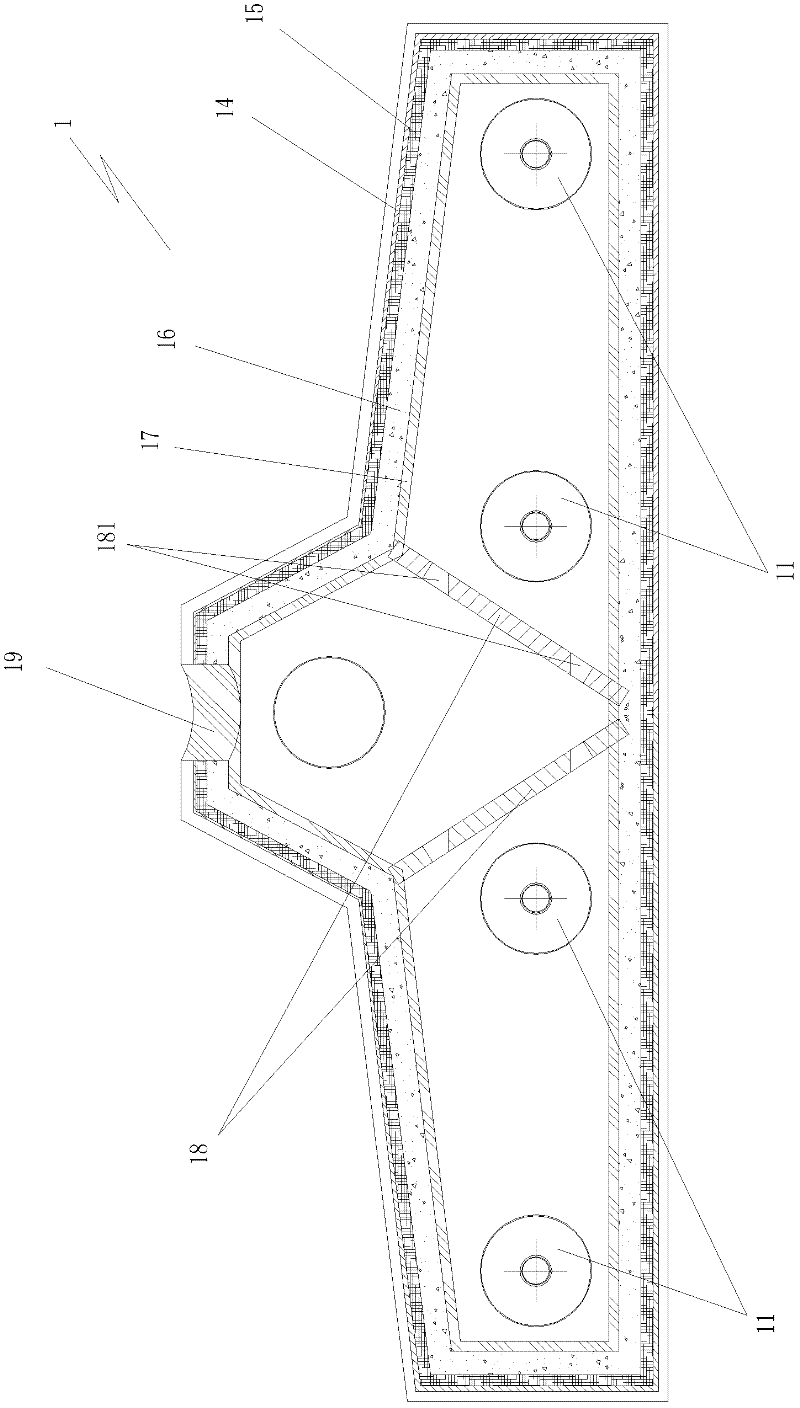

[0038] Such as figure 2 As shown, the present invention also proposes a tundish 100 with the above electromagnetic heating nozzle 3, the tundish 100 is composed of a package body 1, a cover 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com