Cold heading forming process for seamless chain roller and punch pin head for cold heading forming bottom punching

A molding process and seamless chain technology, applied in the field of punching needles, can solve problems affecting the quality of the outer surface of the workpiece, affecting the glossiness of the inner surface of the product, and unbalanced force points in plastic molding, so as to improve the mechanical properties and ensure the outer surface. The effect of surface quality and grain structure compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

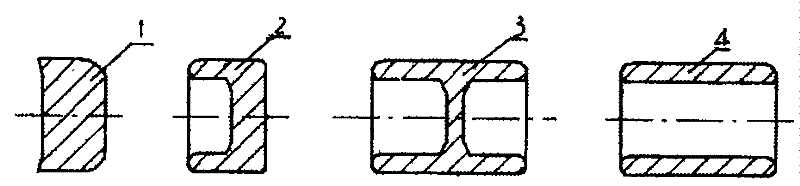

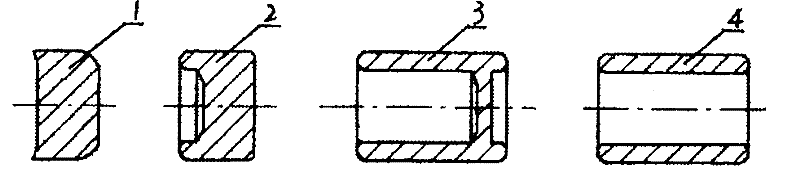

[0014] Such as image 3 As shown, a seamless chain roller cold heading forming process includes feeding, cutting, flattening, upsetting blank 1, reversal, head punching 2, reversal, second punching 3 and bottom punching 4, and the upset blank is first The head punching depth after inversion is controlled within the range of 2-5mm, so as to minimize the extrusion deformation of this process and reduce the occurrence of concave-convex lines in the secondary stamping process. Then control the bottom thickness of the second punch after inversion within the range of 0.5-2mm, so as to prevent the wire drawing of the workpiece head caused by the bottom thickness, which will affect the quality of the product, and is conducive to strengthening the bottom punch The repair function of the process on the inner hole wall and outer surface of the upset embryo.

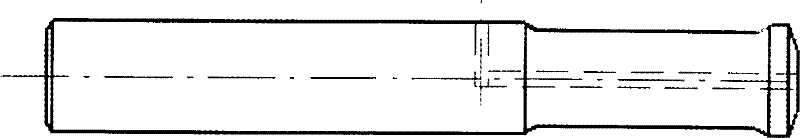

[0015] Such as Figure 4 As shown, a punch head for cold heading forming punching bottom, including the front head of the cylind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com