Manufacturing method of ultrathin semiconductor device

A manufacturing method, semiconductor technology, applied in the direction of semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of inability to realize chip transfer operations, fragments, easy deformation, etc., and achieve the effect of low cost, simple operation, and easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

[0029] A method for manufacturing an ultra-thin semiconductor device, which can be realized in the following steps:

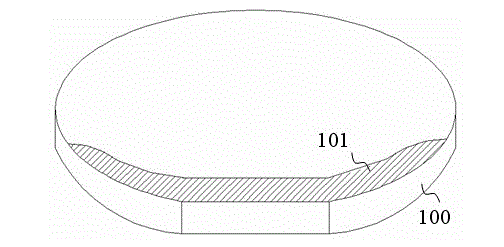

[0030] (1) Refer to figure 1 Prepare a silicon wafer with a thickness of 0.2-0.7 mm, the same diameter and flat side as the ultra-thin product sheet, polished upper surface and ground lower surface as the lining 100, on the upper surface of the flat side and flat sides of the silicon lining 100 Negative photoresist 101 is continuously and evenly coated on the peripheral area of the negative photoresist, the thickness of the negative photoresist is less than 1 millimeter, and the width is within 3 millimeters from the periphery.

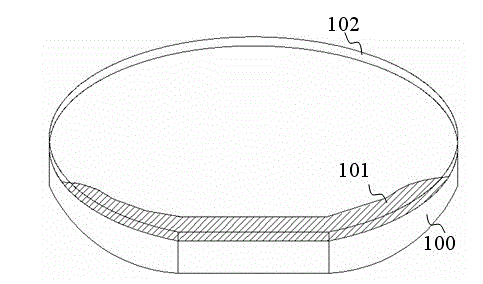

[0031] (2) Refer to figure 2 , put the surface of the ultra-thin silicon product sheet on the upper surface of the silicon lining and stick it on the upper surface of the silicon lining. Keep the flat sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com