Multi-layer fabric and its weaving process

A fabric and process technology, applied in the field of multi-layer fabrics and its weaving process, can solve the problems of inability to produce super-heavy fabrics, and achieve the effect of less difficulty in weaving, less consumption and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

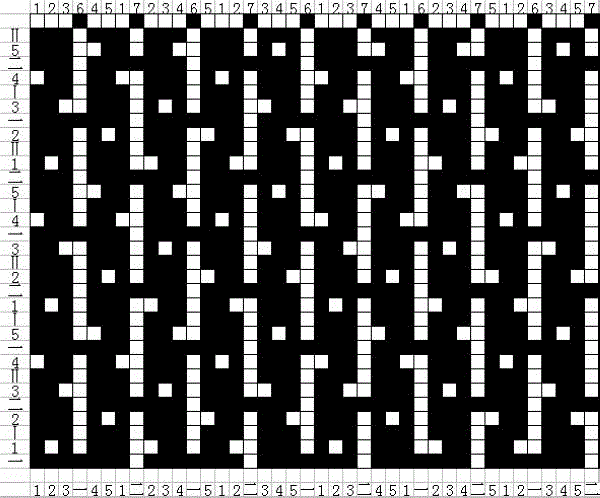

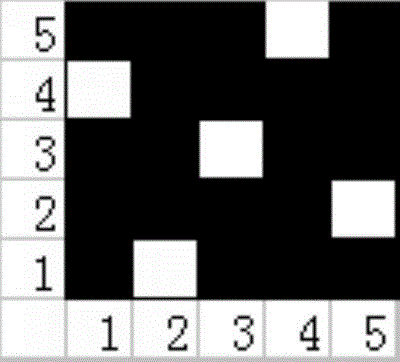

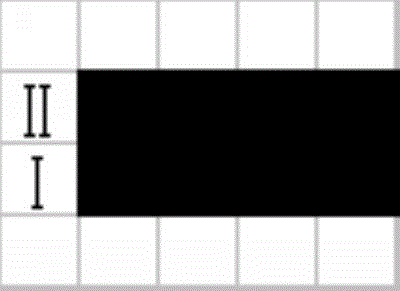

[0033] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 As shown, the surface fabric is designed as five pieces of 2 flying satin weave, the middle fabric is filler, not interwoven with warp yarns, and the bottom fabric is designed as plain weave ( figure 1 The number above is the corresponding wearing method).

[0034] The wearing method is 1, 2, 3, 6+4, 5, 1, 7+2, 3, 4, 6+5, 1, 2, 7+3, 4, 5, 6+1, 2, 3, 7 +4, 5, 1, 6+2, 3, 4, 7+5, 1, 2, 6+3, 4, 5, 7 (the number represents the number of heald frames on which the warp yarn is worn, "+" and " +" indicates that these warp yarns are worn in one reed dent, 1, 2, 3, 4, 5 indicate the frame number of the warp yarn on the surface layer, and 6, 7 indicate the frame number of the warp yarn on the lower layer)

Embodiment 2

[0035] Embodiment 2: as Figure 5 , Image 6 , Figure 7 , Figure 8 As shown, the surface fabric is designed as a plain weave, the middle fabric is a filler, not interwoven with the warp, and the bottom fabric is designed as a twill weave ( Figure 5 The number above is the corresponding wearing method).

[0036] Wearing method: 1, 2, 3, 5+4, 1, 2, 6+3, 4, 1, 7+2, 3, 4, 5+1, 2, 3, 6+4, 1, 2, 7+3, 4, 1, 5+2, 3, 4, 6+1, 2, 3, 7+4, 1, 2, 5+3, 4, 1, 6+2, 3, 4, 7 ( The number represents the number of heald frames on which the warp yarns are worn, the distance between "+" and "+" indicates that these warp yarns are worn in one reed tooth, 1, 2, 3, 4 indicate the page frame numbers of the warp yarns on the surface layer, 5, 6 , 7 means the frame number of the lower warp yarn page)

Embodiment 3

[0037] Embodiment 3: as Figure 9 , Figure 10 , Figure 11 , Figure 12 As shown, the surface fabric is designed as a twill weave, the middle fabric is a filler, not interwoven with the warp, and the bottom fabric is designed as a plain weave ( Figure 9 The number above is the corresponding wearing method).

[0038] The wearing method is: 1, 2, 3, 4+1, 2, 3, 5 (numbers indicate which pages the warp yarns are worn on the heald frame, and the space between "+" and "+" means that these warp yarns are worn on a reed In the teeth, 1, 2, 3 represent the surface warp frame number, 4, 5 represent the lower warp frame number)

[0039] The specific implementation process steps of the present invention are: winding process→warping process→sizing process→reeding process→weaving process→finishing process:

[0040] (1) Winding process: use a fully automatic winder to wind the bobbin into a large-capacity, well-formed bobbin with a certain density, and remove impurities to remove defe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com