Method for improving thermophysical property of coking inhibition silicon/sulfur composite coating of ethene cracking apparatus

A thermophysical property, ethylene cracking technology, applied in coating, metal material coating process, cracking and other directions, can solve the problems of thermal stress concentration, large difference, low bonding strength between coating and substrate, etc., to achieve easy operation, The effect of prolonging the service life and improving the thermophysical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0019] The coating of the coke-suppressing silicon / sulfur composite coating is carried out in the pilot plant for evaluation of coking by high-temperature pyrolysis of hydrocarbons described in the patent CN101113366A. The pilot plant has a good effect on the evaluation of high-temperature pyrolysis coking of hydrocarbons, and can effectively solve the problem of difficulty in scaling up the laboratory results of surface coating coking suppression technology, and provides a reliable basis for the industrial implementation of surface coating coking suppression technology in ethylene cracking furnace Equipment Warranty.

[0020] After the cracking process is over, the pilot cracking furnace tube is decoked. The coke cleaning atmosphere is a mixture of air and water vapor. At the same time, the infrared gas analyzer was used to monitor the CO at the outlet of the cracking furnace tube 2 Volume fraction. When the furnace tube exits CO 2 When the volume fraction is less than 0....

example 2

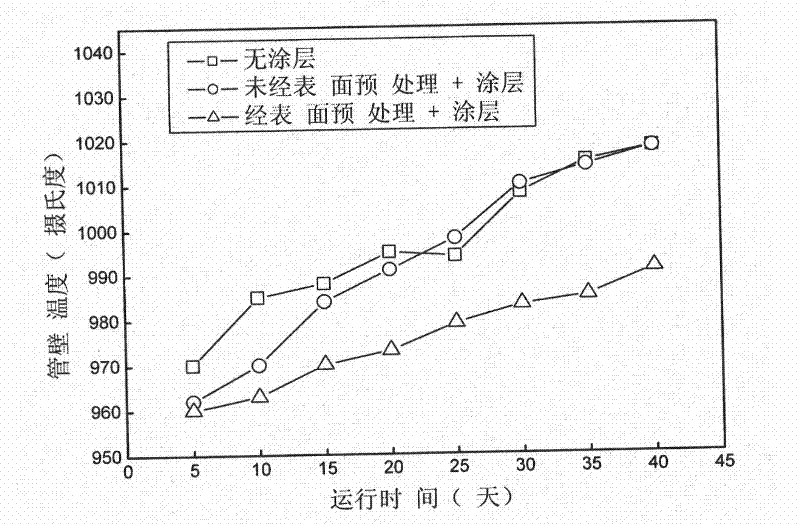

[0029] A small industrial furnace was selected for the coating test of the coke-suppressing silicon / sulfur composite coating. When the outlet temperature was 830°C, the average ethane feed was 5 tons / hour, and the operation period was 40 days. The radiant section coil is made of HK40 alloy and is divided into two processes.

[0030] After the cracking process is over, the cracking furnace tube is decoked. The coke cleaning atmosphere is a mixture of air and water vapor. At the same time, the infrared gas analyzer was used to monitor the CO at the outlet of the cracking furnace tube 2 Volume fraction. When the furnace tube exits CO 2 When the volume fraction is less than 0.2%, scorching ends.

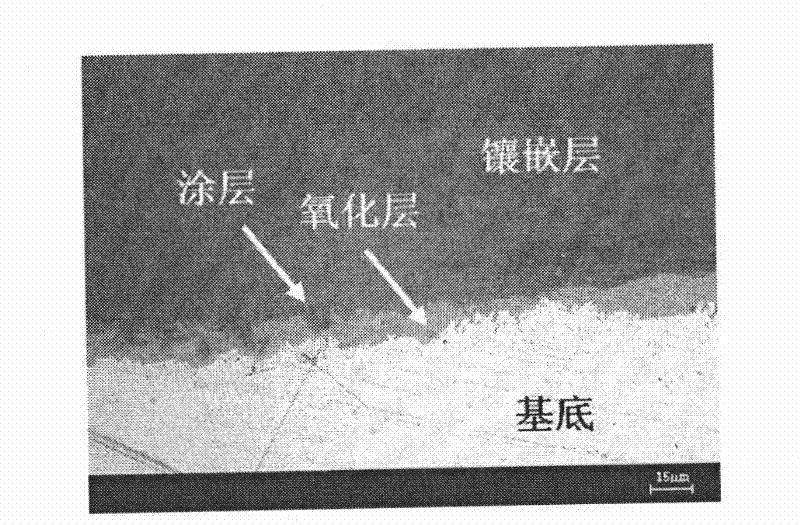

[0031] Use water vapor to carry out pre-oxidation treatment on the metal sample, the temperature is 800°C, and the pre-oxidation time is 2-6 hours.

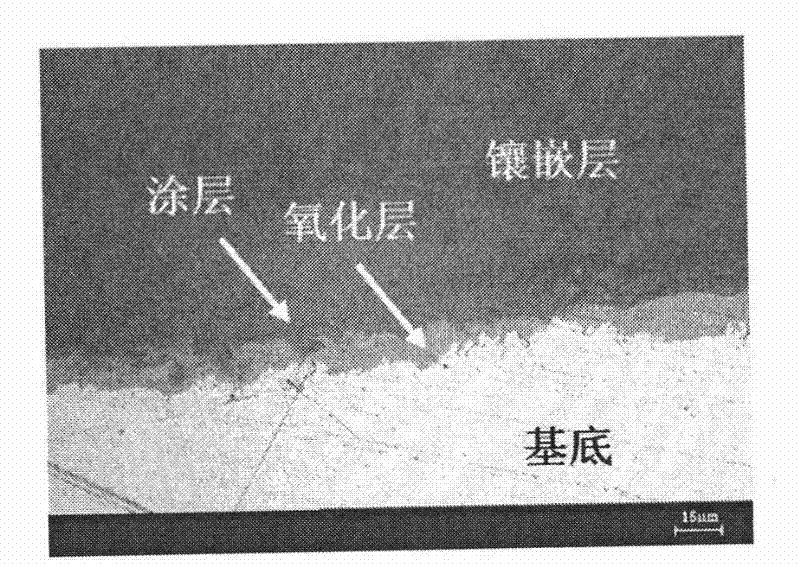

[0032] Coke-cleaned ethylene cracking furnace tubes are coated with a silicon / sulfur composite coating. The specific method and proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Microhardness | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com