Ultrasonic bonding method and special ultrasonic welding machine used for optoelectronic device packaging

A photoelectric device and ultrasonic technology, applied in the direction of electric solid devices, electrical components, semiconductor devices, etc., can solve the problems of complex equipment structure, high packaging cost, high equipment cost, etc., to ensure packaging quality, improve service life, and reduce stress concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In conjunction with accompanying drawing, preferred embodiment of the present invention is described in detail as follows:

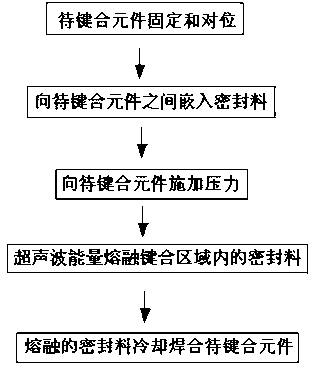

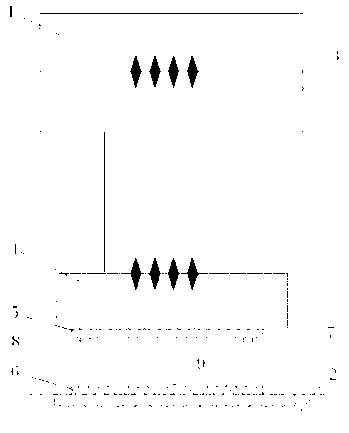

[0039] see Figure 1 ~ Figure 3 , the ultrasonic bonding method that the present invention is used for optoelectronic device packaging comprises the steps:

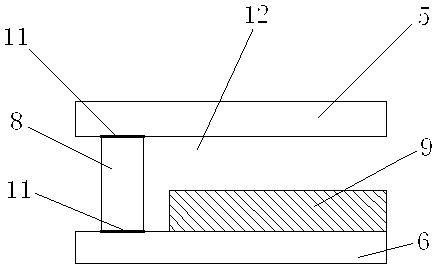

[0040] a. Fix and accurately align the glass cover plate 5 and the glass substrate 6 to be bonded by using the clamping member;

[0041] b. Insert glass sealant between the glass cover plate 5 and the glass substrate 6 in step a, the glass sealant embeds the gap between the glass cover plate 5 and the glass substrate 6, and forms a glass seal 8, the glass cover plate 5 The bonding surface area 11 that forms direct contact with the glass substrate 6 and the glass seal 8 respectively;

[0042] c. Apply initial pressure to the glass cover plate 5 and glass substrate 6 in step b, so that the glass cover plate 5 and glass substrate 6 clamp the glass seal 8;

[0043] d. Utilize the ultrasonic ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com