Technology and system of flame retardation ABS production with weight loss scale automatic batching

An automatic batching and production system technology, applied in the field of flame retardant ABS production, can solve the problems of flame retardant, impact strength and thermal stability, difficult to protect the health of workers, and large dust at the production site. The effect of cleanliness and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

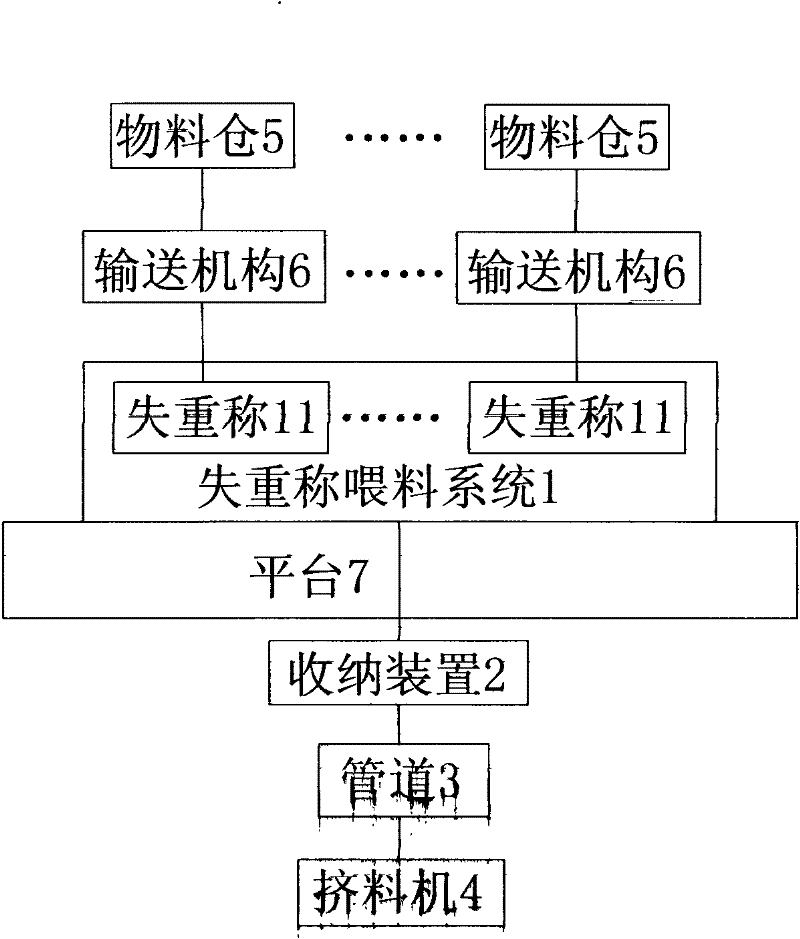

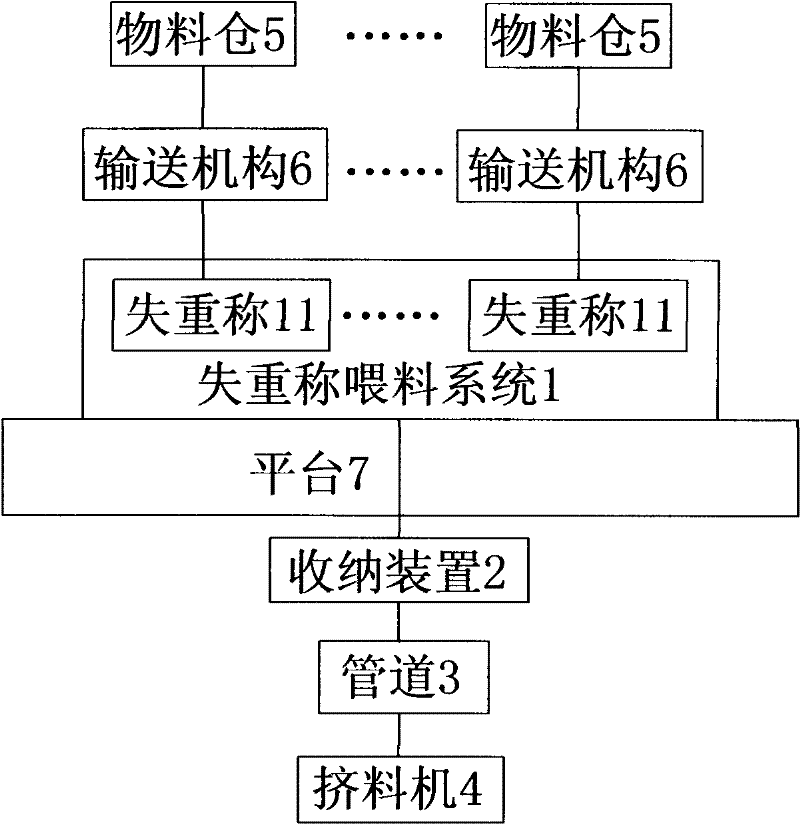

[0021] like figure 1 As shown, the process of producing flame-retardant ABS with the automatic batching of weight loss scale includes the following steps:

[0022] A. Feeding: The various materials used for the production of flame-retardant ABS are transported to the loss-in-weight feeding system 1, which includes several loss-in-weight scales 11 and each loss-in-weight scale 11 receives a material respectively . Various materials used to produce flame-retardant ABS are stored in respective material bins 5 , and a conveying mechanism 6 is provided between each material bin 5 and the weight loss scale 11 .

[0023] B. Automatic metering and continuous feeding: the loss-in-weight scale feeding system 1 receives formula instructions and output instructions, and under the control of formula instructions and output instructions, each loss-in-weight scale 11 continuously quantitatively feeds different materials according to the weight ratio of the materials . The weightlessness s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com