Method for producing glue-free fiber board by using dry method of steam explosion slurry

A fiberboard and pulp technology, which is applied in the field of high-density glue-free fiberboard, can solve the problems of complicated preparation process, high corrosion of equipment, increase production cost, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

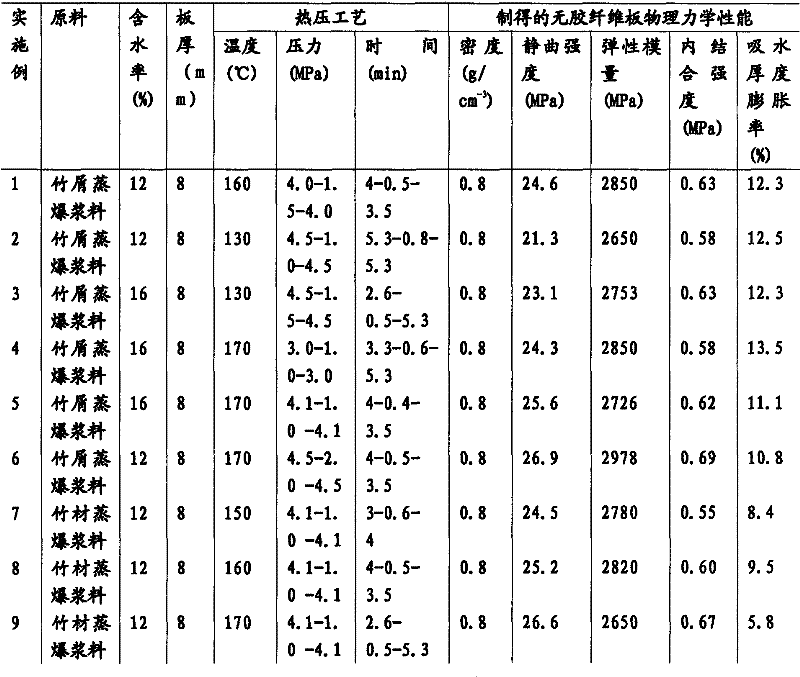

Examples

Embodiment 1

[0023] Example 1: Dry the bamboo chips to a moisture content of 3mm to ≤ 3mm, then mix it with the fine material separated from the original, and air-dry it together until the moisture content is 12%, and then press the middle The conventional process of MDF production is paved and hot-pressed. The hot-pressing temperature is 160 ° C. The hot-pressing pressure in the hydrolysis section and the plasticizing section is 4.0 MPa, and the hot-pressing pressure in the exhaust section is 1.5 MPa. The hot-pressing time in the hydrolysis section is 4 minutes. The hot pressing time of the exhaust section is 0.5min, and the hot pressing time of the plasticizing section is 3.5min. Finally, post-processing is performed on the pressed glue-free bamboo fiber board.

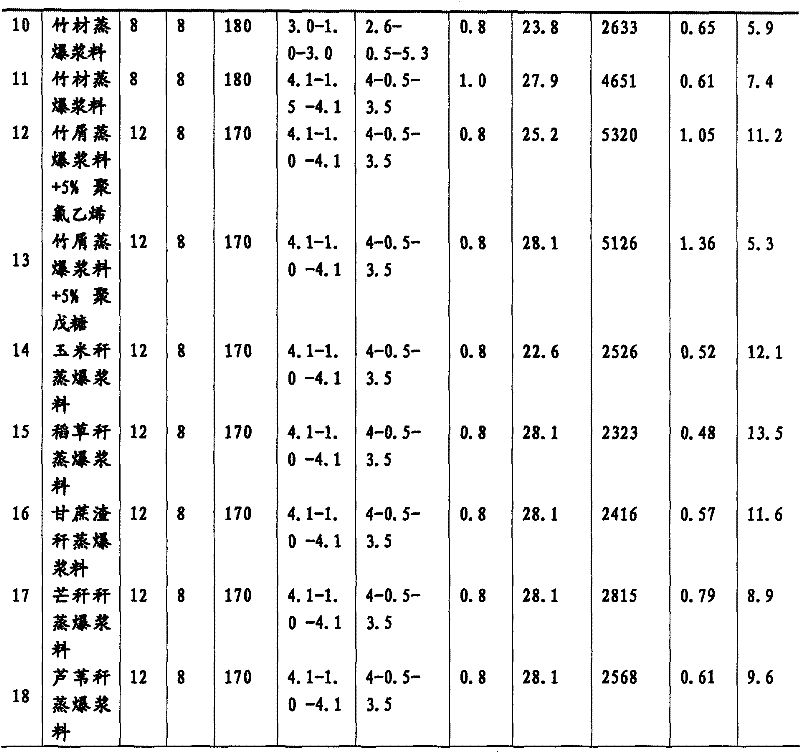

Embodiment 2-18

[0024] The rest of Examples 2-18 can be carried out with reference to the method of Example 1, wherein the gramineous plant raw materials, according to the different forms of the raw materials, are differently truncated or sliced, dried naturally, with a moisture content of <10%, and steamed The water vapor injected into the tank is pressurized at 1.2-1.6MPa, the pressure holding time is 6-12 minutes, and then the pressure is raised to 1.6-1.8MPa. When hot pressing on the press, the pressure value and control are divided into three stages. For the value of heat pressing time, just refer to the values listed in the table, and will not list them one by one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com