Oil sampling tool for main transformer

A main transformer and oil sampling technology, applied in sampling devices and other directions, can solve the problems of pollution, easy to damage the site environment, easy to drip, etc., to achieve the effect of clean working environment, avoid oil sample pollution, and shorten working time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

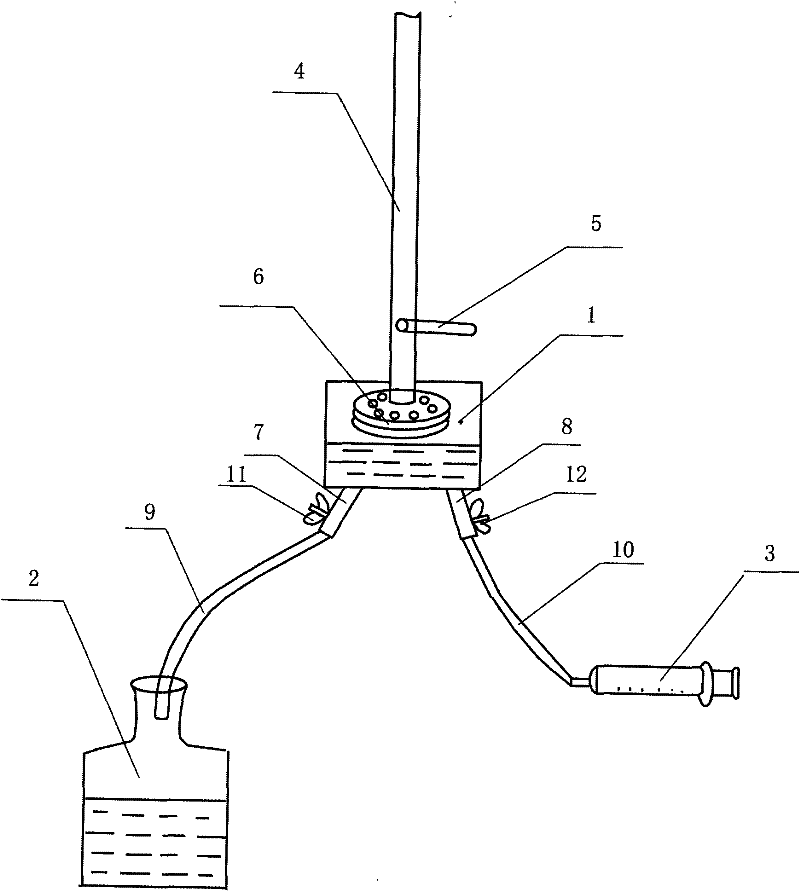

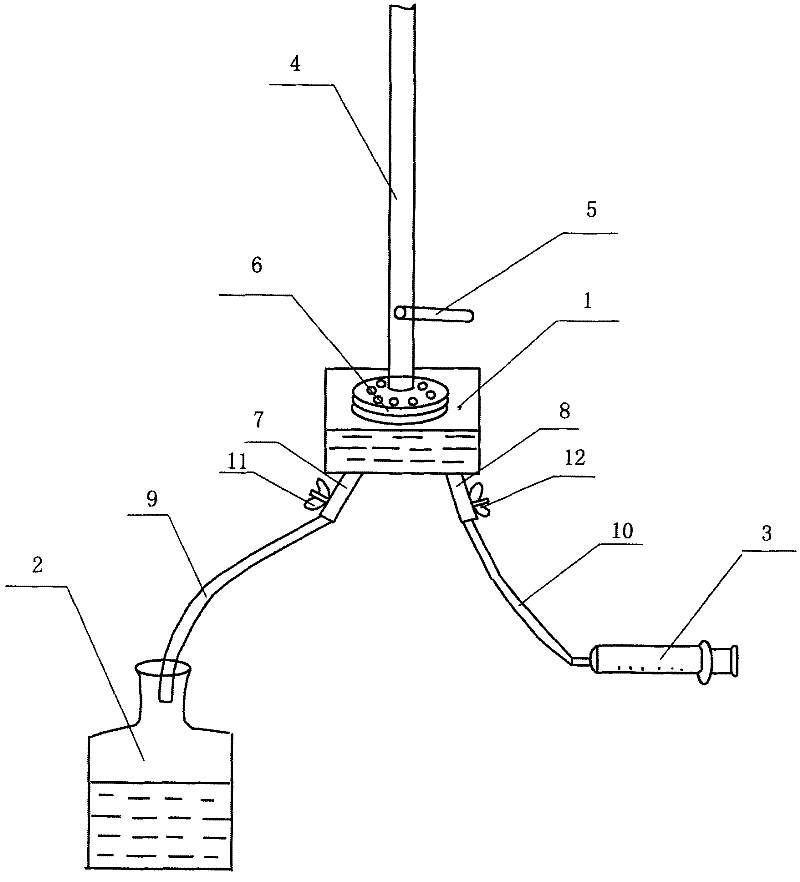

[0008] exist figure 1 Among them, the present invention is an oil sampling tool for a main transformer, a sampling bottle 1, a waste oil bottle 2 and a vacuum sampling device 3, the vacuum sampling device 3 is set as a vacuum syringe, and one end of the main transformer oil pipe 4 extends into the In the sampling bottle 1, an oil discharge valve 5 is provided on the main transformer oil pipe 4, and a sampling valve 6 is provided at the end where the main transformer oil pipe 4 extends into the sampling bottle 1. The sampling valve 6 is located in the sampling bottle 1, and the The bottom of the bottom is provided with oil leakage port I 7 and oil leakage port II 8 respectively, and oil leakage port I 7 and oil leakage port II 8 places are respectively provided with valve I 11 and valve II 12, on oil leakage port I 7 through pipeline I 9 communicates with the waste oil bottle 2, and communicates with the inlet of the vacuum sampling device 3 through the pipeline II 10 on the oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com