Spheroidizing treatment technology by rush-in method

A treatment process and spheroidizing agent technology, which is applied in the field of spheroidizing treatment process by rushing method, can solve the problems of intensified burning of the spheroidizing agent, unsatisfactory effect, and increased labor intensity, so as to increase safety and reduce spheroidization. The effect of long time and improved working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

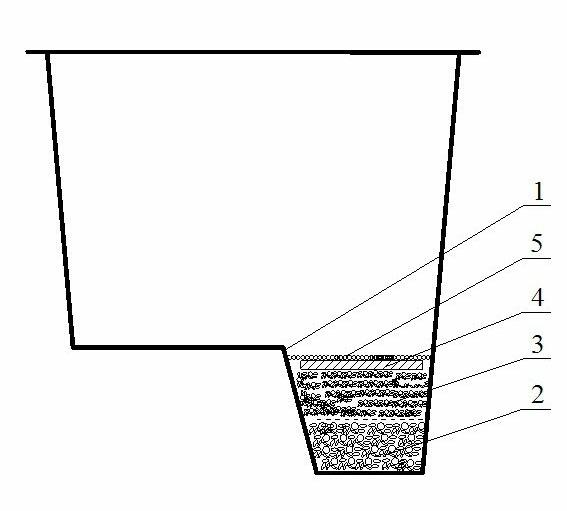

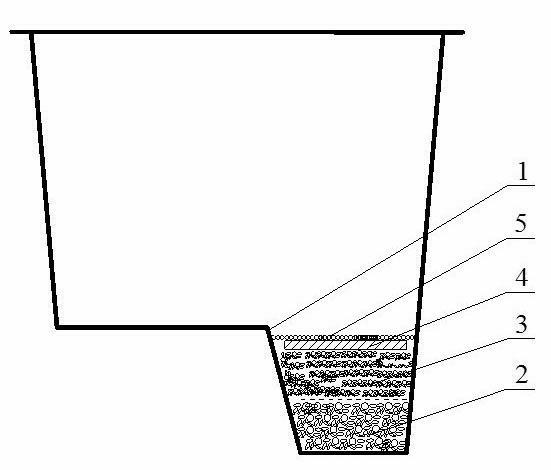

[0026] Embodiment one: see figure 1 .

[0027] A kind of spheroidization process of flushing, comprising the following steps,

[0028] (1) Sequentially add nodulizer 2 and inoculant 3 into ladle pit 1 or dam;

[0029] (2) Cover nodulizer 2 and inoculant 3 with nodular iron plate 4;

[0030] (3) Sprinkle covering agent 5 on ball iron plate 4;

[0031] (4) Pour the molten iron into the ladle;

[0032] (5) After the spheroidization reaction is sufficient, sprinkle a layer of slag collecting agent and remove slag.

[0033] The covering agent 5 is perlite, and can also be other perlite-based covering agents.

[0034] The covering thickness of the covering agent 5 on the nodular iron plate 4 is 2 mm.

[0035] The ductile iron plate 4 is cast from remaining nodular iron molten iron, and its thickness is 8 mm. Using the remaining ductile iron to cast ductile iron plates will not introduce new impurities into the ductile iron.

[0036] In this example, the spheroidization react...

Embodiment 2

[0037] Embodiment two: the diagram is omitted. It is basically the same as the first embodiment, and the similarities will not be repeated. The only difference is that the coating thickness of the covering agent 5 on the ductile iron plate 4 is 4 mm.

[0038] The ball iron plate 4 thickness is 10mm.

[0039] In this example, the spheroidization reaction time was extended by 70%.

Embodiment 3

[0040] Embodiment three: the figure is sketched. It is basically the same as the first embodiment, and the similarities will not be repeated. The only difference is that the coating thickness of the covering agent 5 on the ductile iron plate 4 is 5 mm.

[0041] Iron plate 4 thickness is 15mm.

[0042] In this example, the spheroidization reaction time was extended by 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com