Cultivated fresh water microalgae and application thereof in production of biodiesel and nervonic acid

A technology of fresh water and microalgae, applied in the direction of microorganism-based methods, microorganisms, biofuels, etc., to achieve the effects of rich content, excellent culture cycle, and excellent oil content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

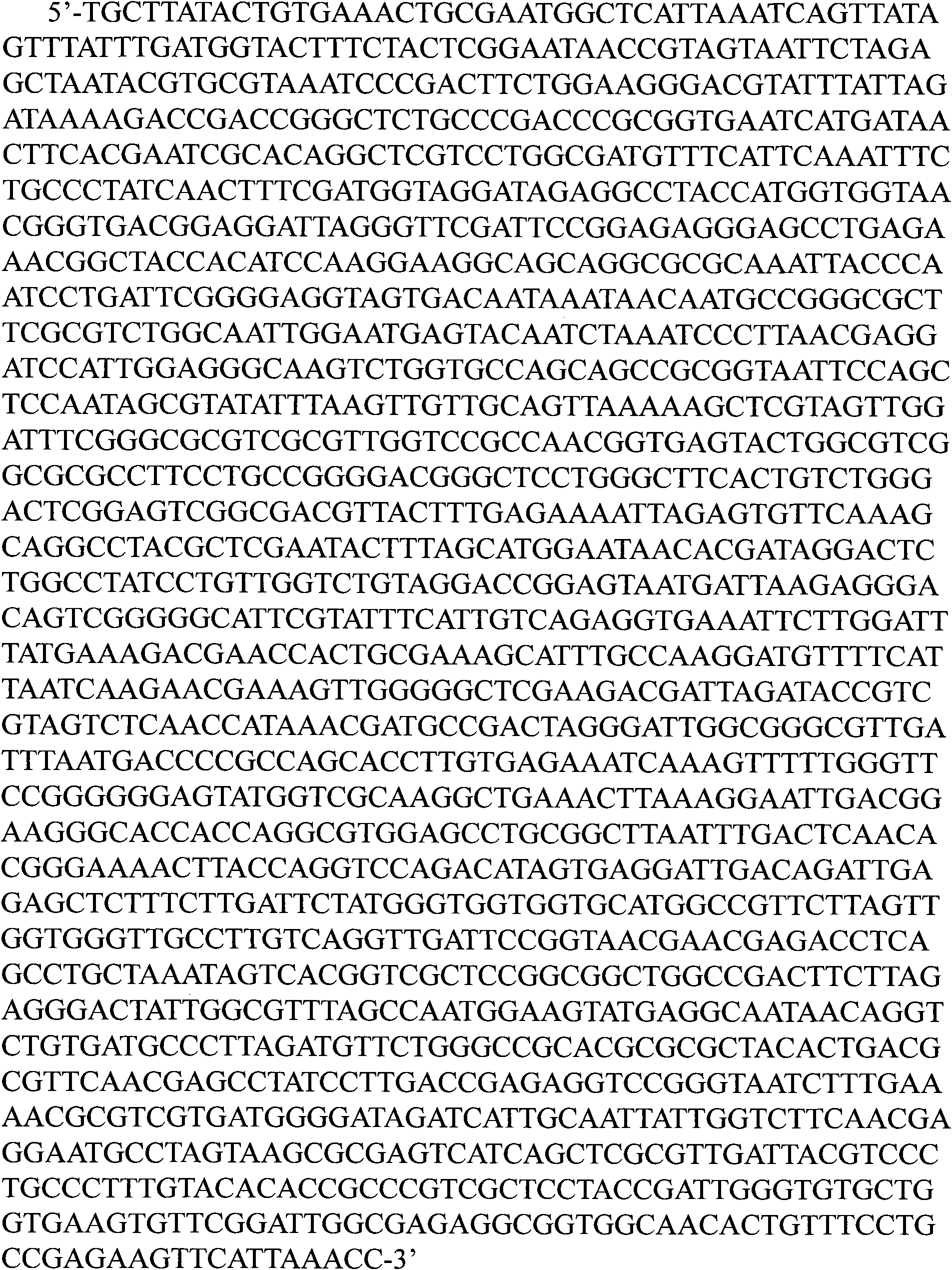

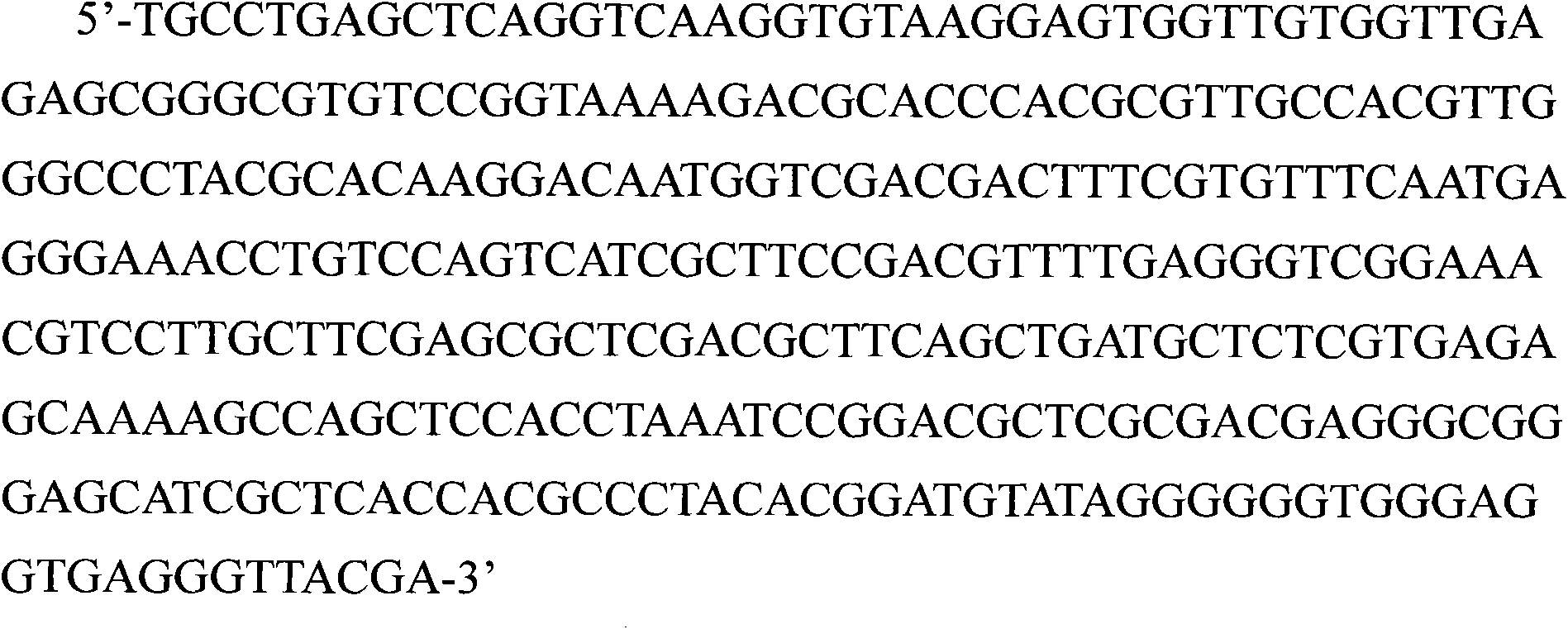

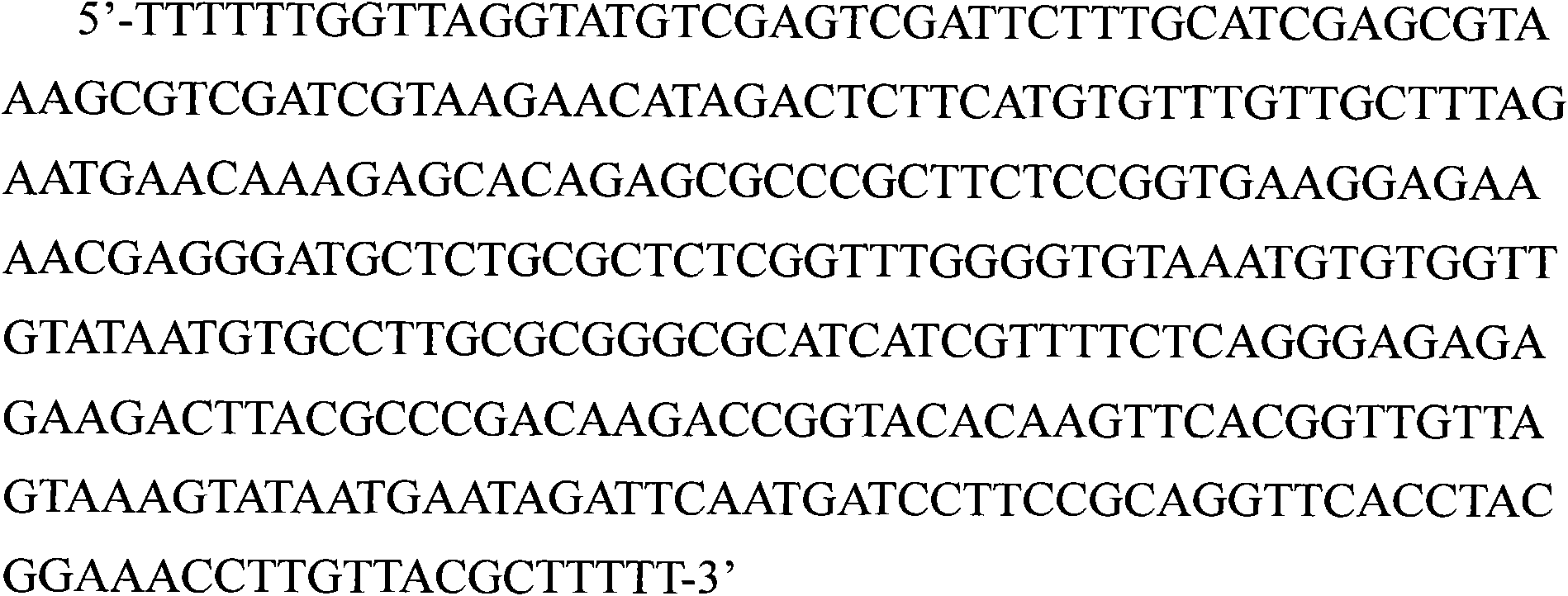

[0030] Example 1: Isolation of Mychonastes sp.HSO-3-1 strain

[0031] Mychonastes sp.HSO-3-1 was isolated in the lotus root pool in the suburbs of Jinan City. The specific process was as follows: take an appropriate amount of water samples from the lotus root pool with a sterile bottle, and spread the BG-11 medium plate under aseptic conditions in the laboratory. Light incubator, cultivate at 25°C until algae colonies appear, pick multiple algae colonies and perform multiple streaking and separation steps until completely purified algae colonies are obtained. One of them, named HSO-3-1, was identified as a species of the genus Mychonastes by 18S rDNA and ITS sequence analysis.

[0032] Pick Mychonastes sp.HSO-3-1 single algae colony on solid plate under aseptic condition, pick the algae colony that obtains purifying through repeatedly streaking (applicant preserved described algae strain on March 4, 2011 In the General Microbiology Center of China Microbial Culture Collection M...

Embodiment 2

[0033] Embodiment 2: the initial cultivation of Mychonastes sp.HSO-3-1 algae liquid

[0034] Under laboratory conditions, the above-mentioned Mychonastes sp.HSO-3-1 was preserved as a test tube slant culture medium, or as a liquid culture medium in an Erlenmeyer flask, and the medium used was BG-11 medium. The activity of the preserved algae species is transferred in a cycle of 2 months. The algae liquid used for inoculation is generally at 200μmol photons m -2 the s -1 OD 750 Reach 2.0, inoculate to contain 50ml sterilized BG-11 culture fluid (NaNO 3 1500mg / L; K 2 HPO 4 40mg / L; MgSO 4 ·7H 2 O 75mg / L; CaCl 2 2H 2 O 36mg / L; Citric acid 6mg / L; Ferric ammonium citrate 6mg / L; Na 2 EDTA 1mg / L; NaCO 3 20mg / L;H 3 BO 3 2.86mg / L; MnCl 2 4H 2 O 1.81mg / L; ZnSO 4 ·7H 2 O 0.222mg / L; NaMoO 4 2H 2 O 0.39mg / L; CuSO 4 ·5H 2 O 0.079mg / L; Co(NO 3 ) 2 ·6H 2 O 0.049mg / L; deionized water 1L, adjust pH to 7.4) in a 100ml Erlenmeyer flask; then cultivate under continuous light...

Embodiment 3

[0035] The expanded culture of embodiment 3 Mychonastes sp.HSO-3-1 algae liquid and its use in the production of oil (the content of sodium nitrate is 0.15g / L)

[0036] The initial algae liquid that embodiment 2 obtains is inoculated in the sterilized BG-11 culture fluid of 250ml (K 2 HPO 4 40mg / L; MgSO 4 ·7H 2 O 75mg / L; CaCl 2 2H 2 O 36mg / L; Citric acid 6mg / L; Ferric ammonium citrate 6mg / L; Na 2 EDTA 1mg / L; NaCO 3 20mg / L;H 3 BO 3 2.86mg / L; MnCl 2 4H 2 O 1.81mg / L; ZnSO 4 ·7H 2 O 0.222mg / L; NaMoO 4 2H 2 O 0.39mg / L; CuSO 4 ·5H 2 O 0.079mg / L; Co(NO 3 ) 2 ·6H 2 (00.049mg / L; 1L of deionized water, adjust the pH to 7.4), wherein the content of sodium nitrate is 0.15g / L, insert the final concentration of cells OD 750 0.2, using a column culture device (diameter 42mm, length 600mm, wall thickness 2mm, material is ordinary glass, the same below), continuous light, light intensity 280 ~ 320μmol photons m -2 the s -1 , the temperature is 24 ℃ ~ 30 ℃, CO 2 The concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com