Improved method for preparing layered enriched lithium-manganese-nickel oxide by low-heat solid-phase reaction

A technology of nickel oxide and low-heat solid phase, which is applied in the direction of manganese oxide/manganese hydroxide, electrical components, battery electrodes, etc., can solve the problems that the microscopic morphology and particle size distribution cannot be effectively controlled, and achieve accelerated reaction-nucleation ―Effects of growth process, simplification of operation process and simplification of process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

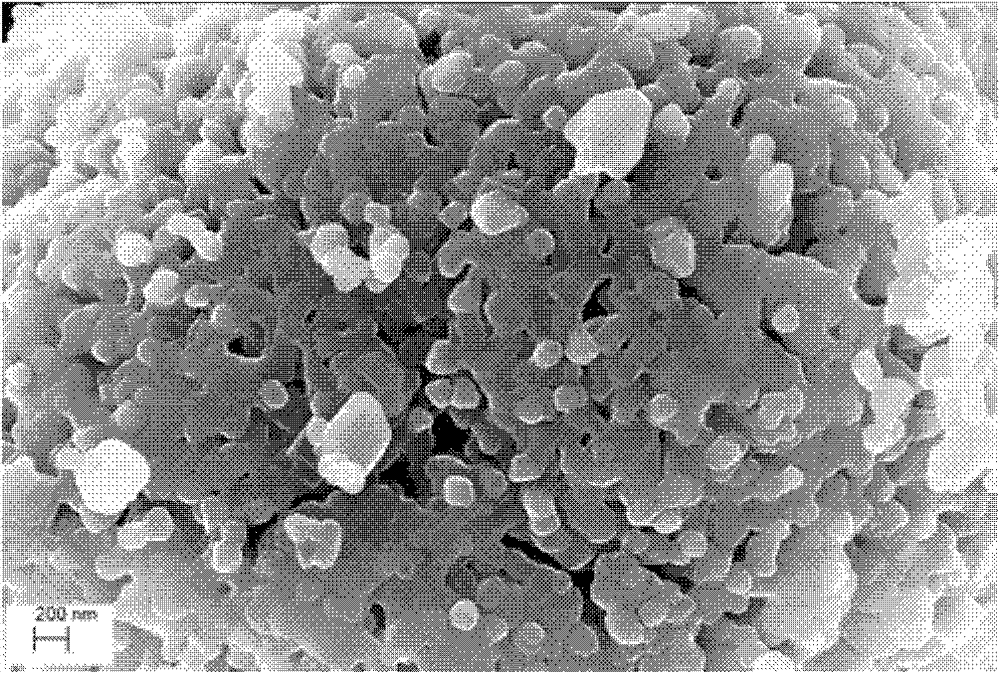

Image

Examples

Embodiment 1

[0026] 1) Lithium hydroxide monohydrate LiOH·H 2 O, dihydrate oxalic acid C 2 h 2 o 4 2H 2 O, nickel acetate and manganese acetate were added to the ball mill at the same time, in which LiOH·H 2 O:C 2 h 2 o 4 2H 2 The molar ratio of O is 1:1, the molar ratio of lithium hydroxide monohydrate to manganese acetate and nickel acetate is 1.2:0.6:0.2, and the ball mill is mixed for 1 hour;

[0027] 2) Add deionized water to the obtained slurry, adjust the concentration to 280g / l, carry out spray drying, and control the temperature of fluid heating at 120°C to obtain dry powder;

[0028] 3) Roast the powder at 450°C for 3 hours, put it into a corundum saggar after ball milling, and heat up to 600°C for 12 hours after pressing to obtain a layered rich powder with high fluidity and a particle size composition controlled at 3-8.5 μm. Lithium manganese nickel oxide Li 1.2 mn 0.6 Ni 0.2 o 2 (Li 1+x mn y Ni 1-x-y o 2, where x=0.2, y=0.6).

Embodiment 2

[0030] 1) Lithium hydroxide monohydrate LiOH·H 2 O, dihydrate oxalic acid C 2 h 2 o 4 2H 2 O, nickel acetate and manganese acetate were added to the ball mill at the same time, in which LiOH·H 2 O:C 2 h 2 o 4 2H 2 The molar ratio of O is 1:1.2, the molar ratio of lithium hydroxide monohydrate to manganese acetate and nickel acetate is 1.3:0.01:0.69, and the ball mill is mixed for 0.8h;

[0031] 2) Add deionized water to the obtained slurry, adjust the concentration to 250g / l, carry out spray drying, and control the temperature of fluid heating at 115°C to obtain dry powder;

[0032] 3) The powder is roasted at 500°C for 6 hours, ball milled, put into a corundum sagger, and then heated to 750°C for 15 hours to obtain a layered lithium-rich layer with high fluidity and particle size composition controlled at 4-12 μm Manganese Nickel Oxide Li 1.3 mn 0.01 Ni 0.69 o 2 (Li 1+x mn y Ni 1-x-y o 2, where x=0.3, y=0.01).

Embodiment 3

[0034] 1) Lithium hydroxide monohydrate LiOH·H 2 O, dihydrate oxalic acid C 2 h 2 o 4 2H 2 O, nickel acetate and manganese acetate were added to the ball mill at the same time, in which LiOH·H 2 O:C 2 h 2 o 4 2H 2 The molar ratio of O is 1:1.15, the molar ratio of lithium hydroxide monohydrate to manganese acetate and nickel acetate is 1.11:0.56:0.33, and the ball mill is mixed for 2 hours;

[0035] 2) Add deionized water to the obtained slurry, adjust the concentration to 220g / l, carry out spray drying, and control the temperature of fluid heating within the range of 110°C to obtain dry powder;

[0036] 3) Roast the powder at 480°C for 4 hours, put it into a corundum sagger after ball milling, and heat up to 850°C for 13 hours after pressing to obtain a layered lithium-rich layer with high fluidity and particle size composition controlled at 3-10 μm Manganese Nickel Oxide Li 1.11 mn 0.56 Ni 0.33 o 2 (Li 1+x mn y Ni 1-x-y o 2, where x=0.11, y=0.56).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com