Wave-absorbing material for silicon carbide fibre reinforced resin base sandwich structure and preparation method thereof

A silicon carbide fiber, reinforced resin-based technology, applied in the field of structural wave absorbing materials, can solve the problems of difficulty in ensuring the stability of wave absorbing properties, deterioration of mechanical properties of composite materials, and difficulty in achieving broadband absorption, etc., and achieves good absorption of electromagnetic waves and good matching. Features, the effect of excellent radar absorbing function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

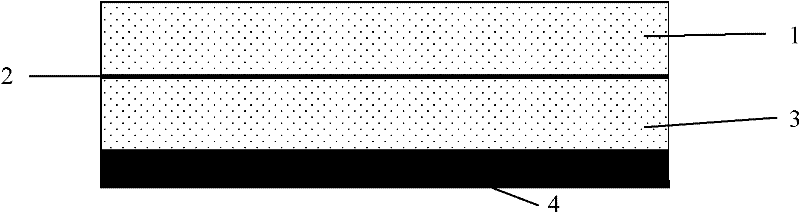

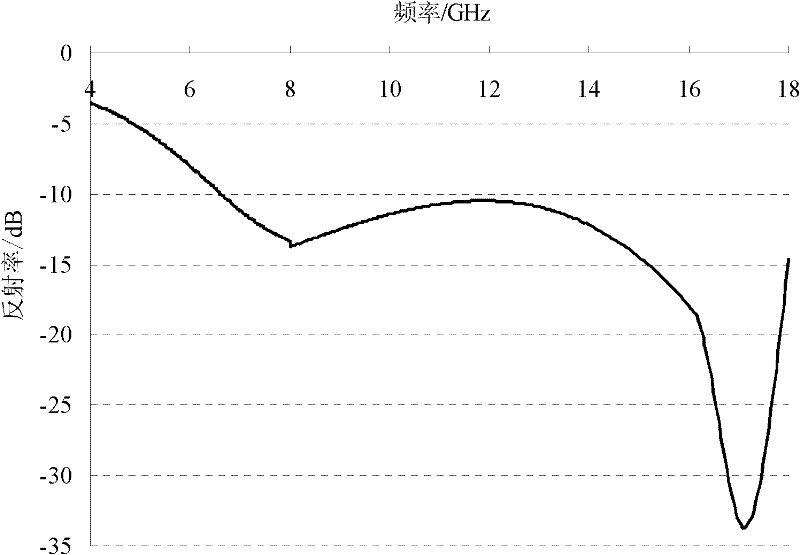

[0023] Such as figure 1 As shown, a silicon carbide fiber-reinforced resin-based sandwich structure absorbing material of the present invention is a multi-functional laminated structure including a first dielectric layer 1, an absorbing layer 2, a second dielectric layer 3 and a reflective layer 4 , each functional layer is composed of continuous silicon carbide fiber-reinforced resin-based composite materials, and the continuous silicon carbide fibers serving as reinforcing materials in each functional layer have different resistivities. In this embodiment, the superimposed structure of the absorbing material of the silicon carbide fiber reinforced resin-based sandwich structure is the first dielectric layer 1, the absorbing layer 2, the second dielectric layer 3 and the reflective layer 4 from the outside to the inside, and the first dielectric layer 1 and the resistivity of the continuous silicon carbide fibers in the second dielectric layer 2 are much greater than the resi...

Embodiment 2

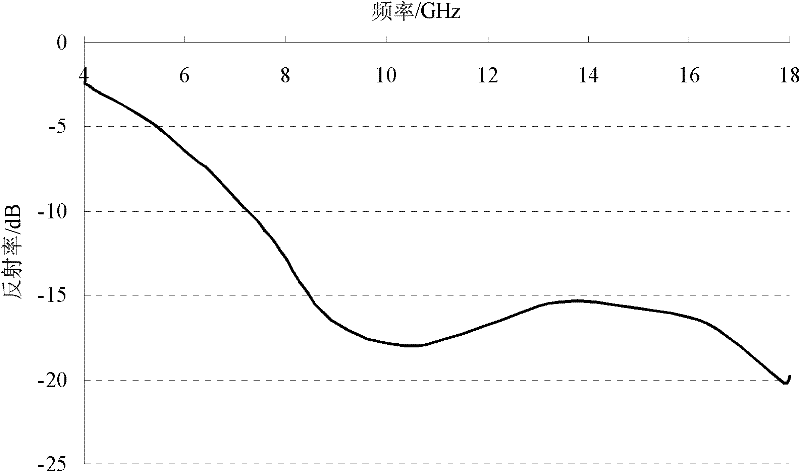

[0035] Such as figure 1 As shown, another silicon carbide fiber-reinforced resin-based sandwich structure absorbing material of the present invention is a multi-functional layer stacking type comprising a first dielectric layer 1, an absorbing layer 2, a second dielectric layer 3 and a reflective layer 4 Structure, each functional layer is composed of continuous silicon carbide fiber-reinforced resin-based composite material, and the continuous silicon carbide fibers serving as reinforcing materials in each functional layer have different resistivities. The superimposed structure of the absorbing material of the silicon carbide fiber-reinforced resin-based sandwich structure is the first dielectric layer 1, the absorbing layer 2, the second dielectric layer 3 and the reflective layer 4 in sequence from the outside to the inside, the first dielectric layer 1 and the second dielectric layer The resistivity of the continuous silicon carbide fibers in the second dielectric layer 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com