Hydrocarbon conversion catalyst regeneration burning method and regenerator burning area structure

A catalyst and coking zone technology, applied in catalyst regeneration/reactivation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as overheating risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

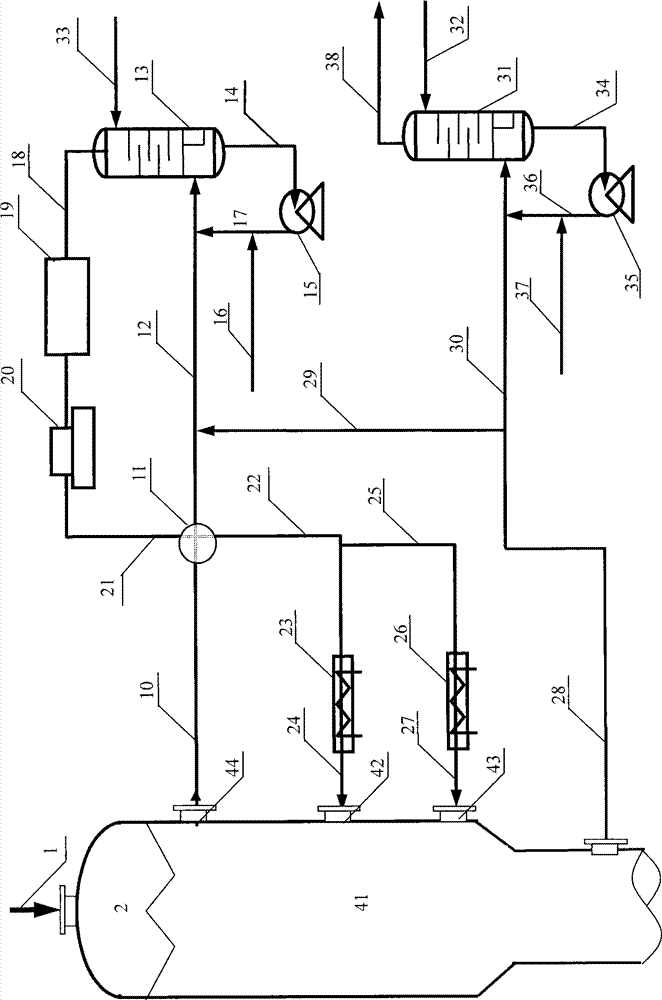

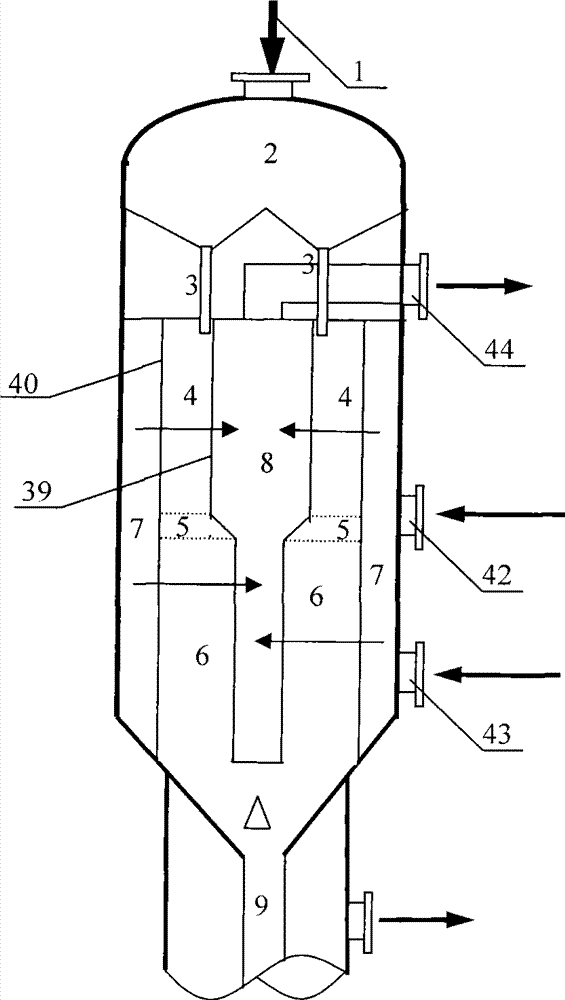

[0034] Such as figure 2 As shown, the catalyst bed layer in the coke area 41 of the regenerator is composed of a cylindrical inner screen 39 and a cylindrical outer screen 40, wherein the upper diameter of the inner screen 39 is larger than the lower diameter, and the upper and lower parts are separated by a Conical connection. The burnt zone 41 of the regenerator is located below the buffer zone 2 and communicated with the catalyst feeding leg 3 .

[0035] The cylindrical upper part of the inner screen 39 and the outer screen 40 constitute the upper fast-burning section 4 of the catalyst bed in the burnt zone, and the cylindrical lower part of the inner screen 39 and the outer screen 40 constitute the upper part of the catalyst bed in the burnt zone. The lower superheating section 6, the conical connection structure part of the inner screen 39 and the outer screen 40 constitute the intermediate transition section 5 of the catalyst bed in the burnt zone. The bed thickness r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com