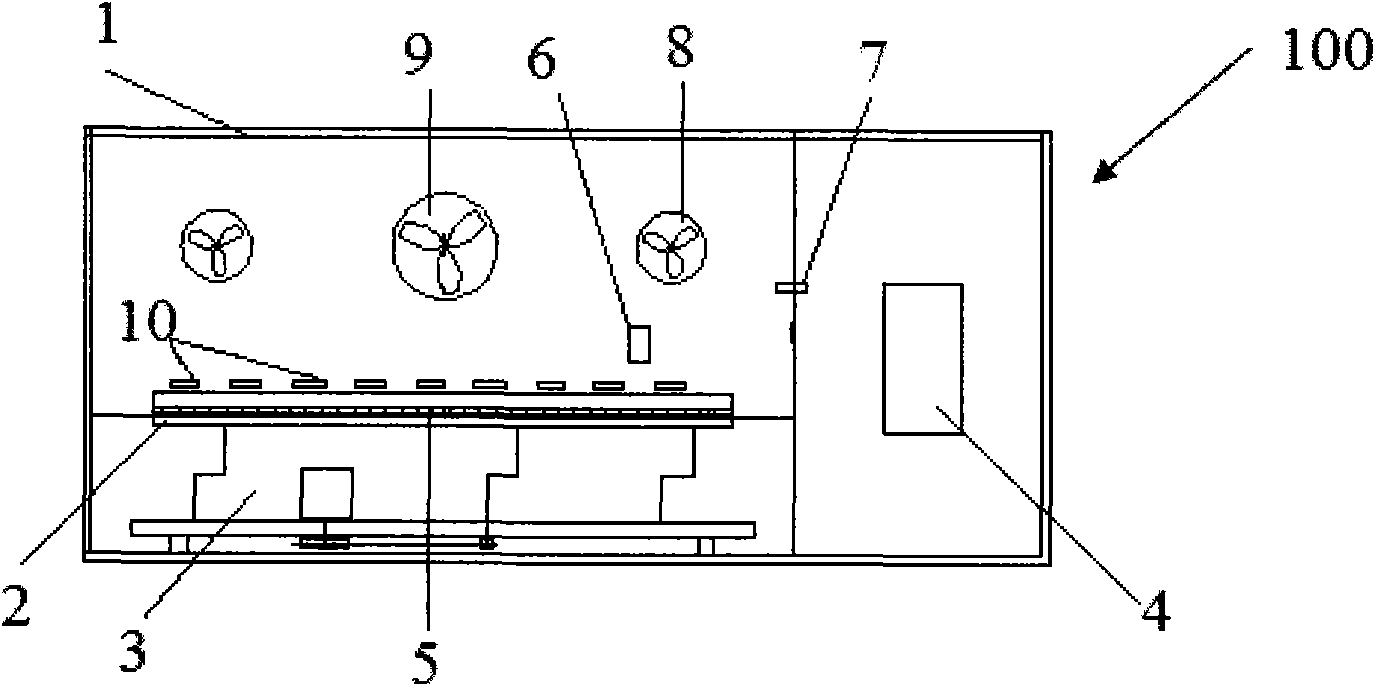

Microalgae high-throughout culture equipment

A microalgae culture, high-throughput technology, applied in biochemical equipment and methods, microorganisms, microorganism-based methods, etc., can solve problems such as difficulty in achieving light and ventilation effects, unsatisfactory light intensity, and large heat production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

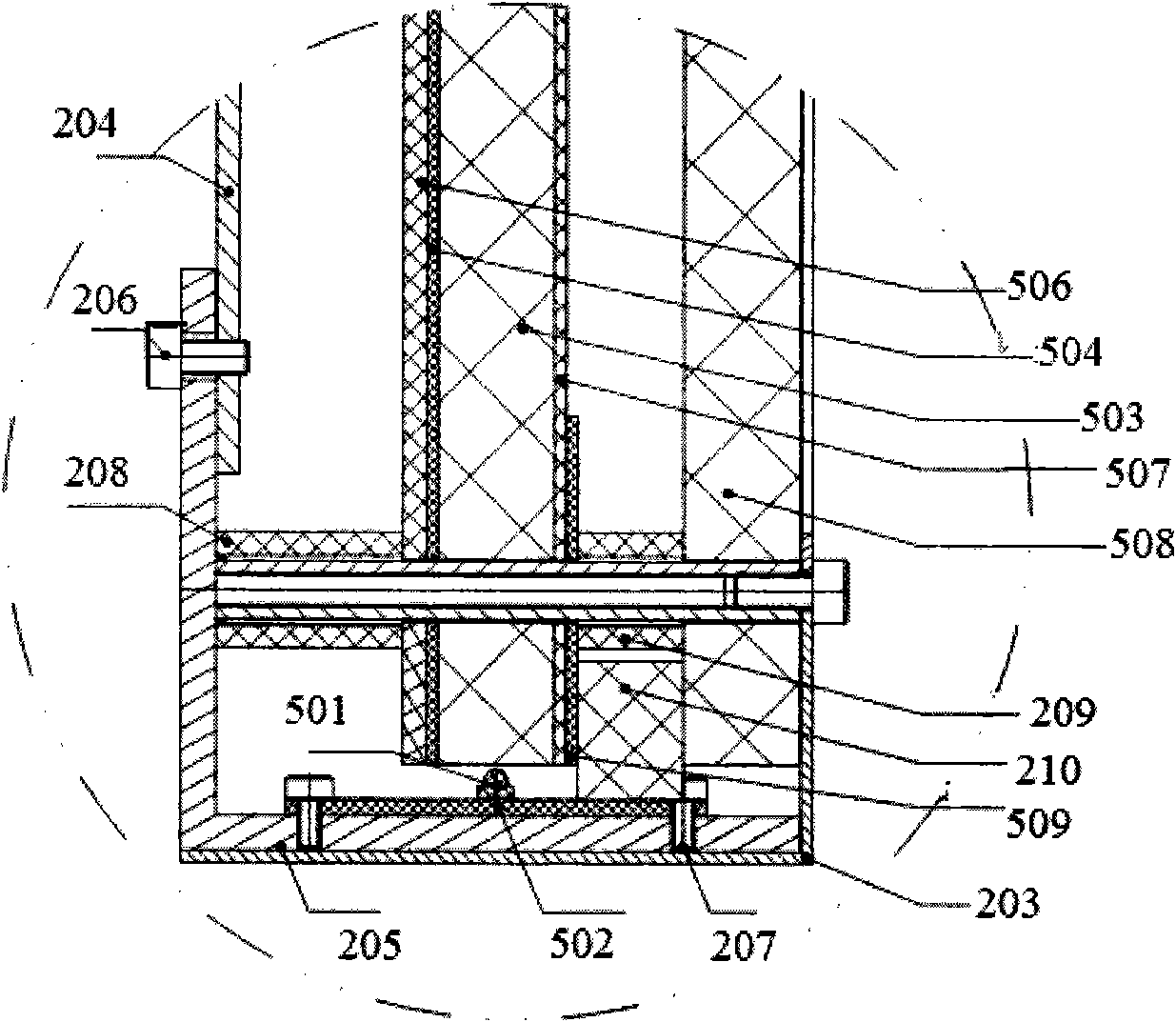

Method used

Image

Examples

Embodiment 1

[0052] In this embodiment, whether the light intensity distribution of the designed shaker meets the requirements of high-throughput screening of microalgae is evaluated by measuring the light intensity at different positions.

[0053] The experimental procedure is as follows: set the temperature of the shaker at 25°C and the light intensity at 4000 lux, and measure the light intensity at the upper left corner, upper right corner, lower left corner, lower right corner and center of the designed shaker with an illuminance meter. A 96-microwell plate was used as the benchmark for measurement.

[0054] Data processing uses SPSS Statistics 17.0 software. The uniformity of illumination among the wells of each microplate was evaluated by calculating the coefficient of variation (CV) of the illumination intensity at each well in each microplate and one-way analysis of variance (ANOVA). The uniformity of illumination at different positions was evaluated by calculating the coefficient...

Embodiment 2

[0058] In this embodiment, 96-well plates, 48-well plates, 24-well plates, and 12-well plates are respectively selected, and the lighting device in the present invention is used to provide light, and the algae strain Chlorella vulgaris (purchased from the Institute of Hydrobiology, Chinese Academy of Sciences, freshwater algae species Library, No. 1068) for cultivation, using BG11 medium (see Table 1-3 below).

[0059] Table 1 Composition and content of BG11 medium

[0060] serial number

Element

Volume ( / L)

1

NaNO 3

1.5g

2

MgSO 4 ·7H 2 o

0.075g

3

CaCl 2 2H 2 o

0.036g

4

0.006g

5

Fe-EDTA stock solution

1mL

6

Na 2 CO 3

0.02g

7

1.0ml

[0061] Table 2A 5 Trace element composition and content

[0062] serial number

Element

Quantity (g / L)

1

h 3 BO 3

2.86

...

Embodiment 3

[0071] In the embodiment, the correlation between the miniaturized culture of algae cells using the high-throughput culture equipment of the present invention and conventional culture methods will be analyzed. Under certain experimental conditions, the comparison of the growth ability of three different algae species in shake flasks and microwell plates is used to evaluate the use of high-throughput culture equipment of the present invention to cultivate microalgae through microwell plates and culture with shake flasks Whether there is a high correlation between microalgae.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com