Methane tank capable of facilitating slag removal

A biogas digester, a convenient technology, applied in the field of biogas digesters, can solve problems such as human injury, death, and abnormal biogas generation, and achieve the effect of increasing gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

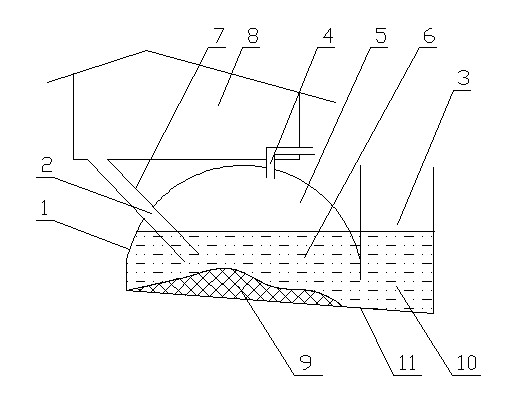

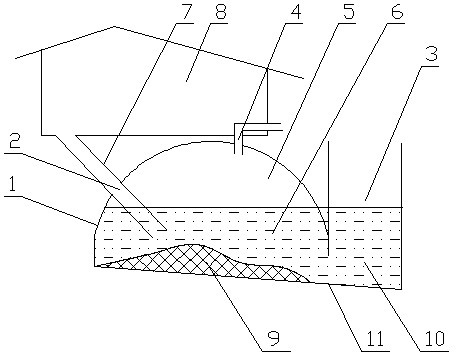

[0017] figure 1 It is a structural schematic diagram of the present invention, as shown in the figure, the biogas digester for removing slag of the present invention includes a biogas digester body 1, and the biogas digester body 1 is provided with a feed port 2, a discharge port 3 and a biogas outlet 4, and the biogas The upper part of the tank body 1 is a gas storage chamber 5, the lower part is a fermentation chamber 6, the bottom surface 11 of the biogas tank body 1 is an inclined plane, the feeding port 2 corresponds to the high position of the inclined plane, and the discharge port 3 corresponds to the low position of the inclined plane; In the present invention, the bottom surface 11 of the biogas tank body 1 is changed from a flat surface to an inclined surface, which improves the fluidity of the biogas residue 9. Mouth 3 transp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com