Automatic continuous apple packaging machine

A packaging machine and apple technology, applied in packaging, transport packaging, food packaging, etc., can solve the problems of high cost, complex structure, low packaging efficiency, etc., and achieve the effect of increasing service life, low cost and high packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

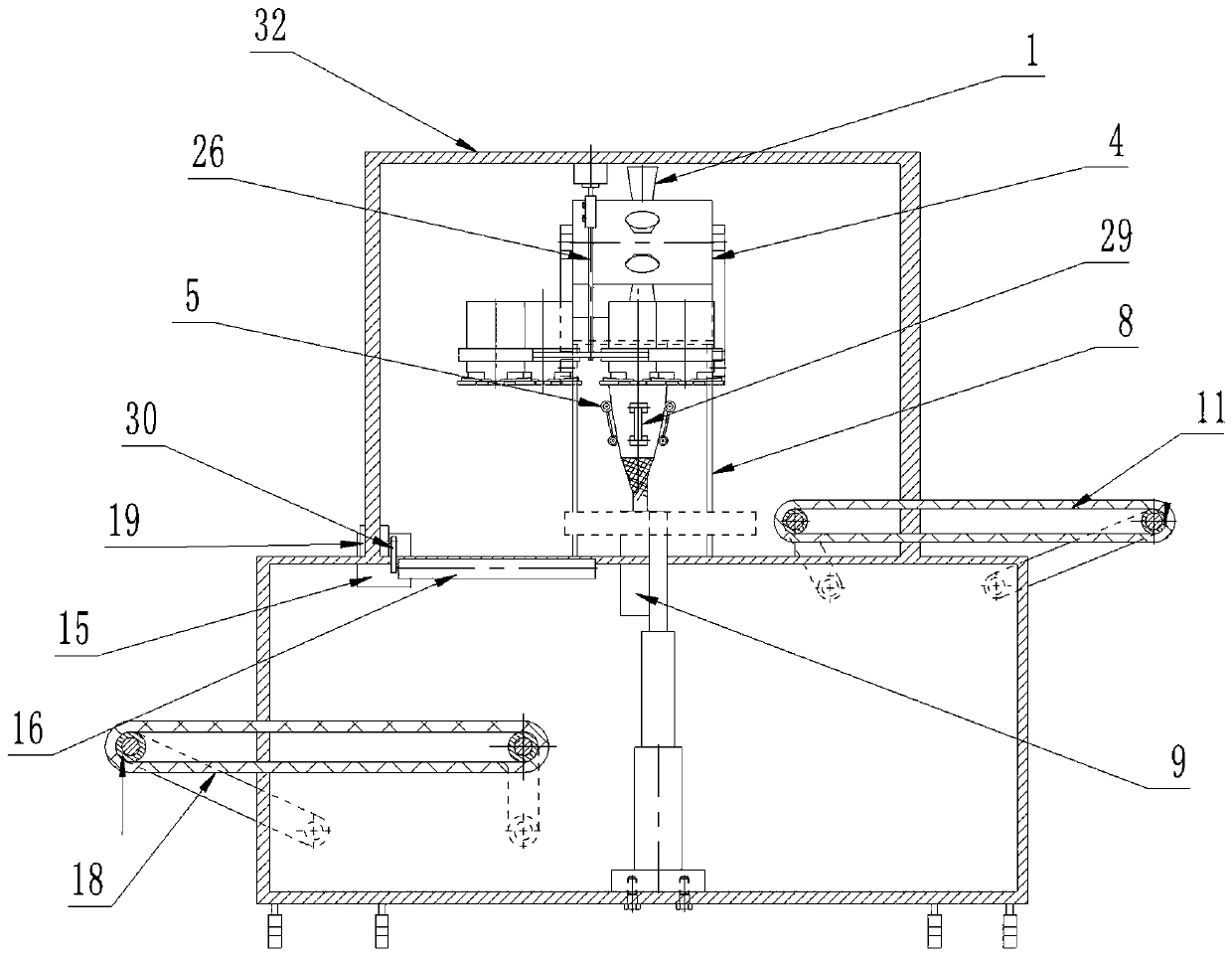

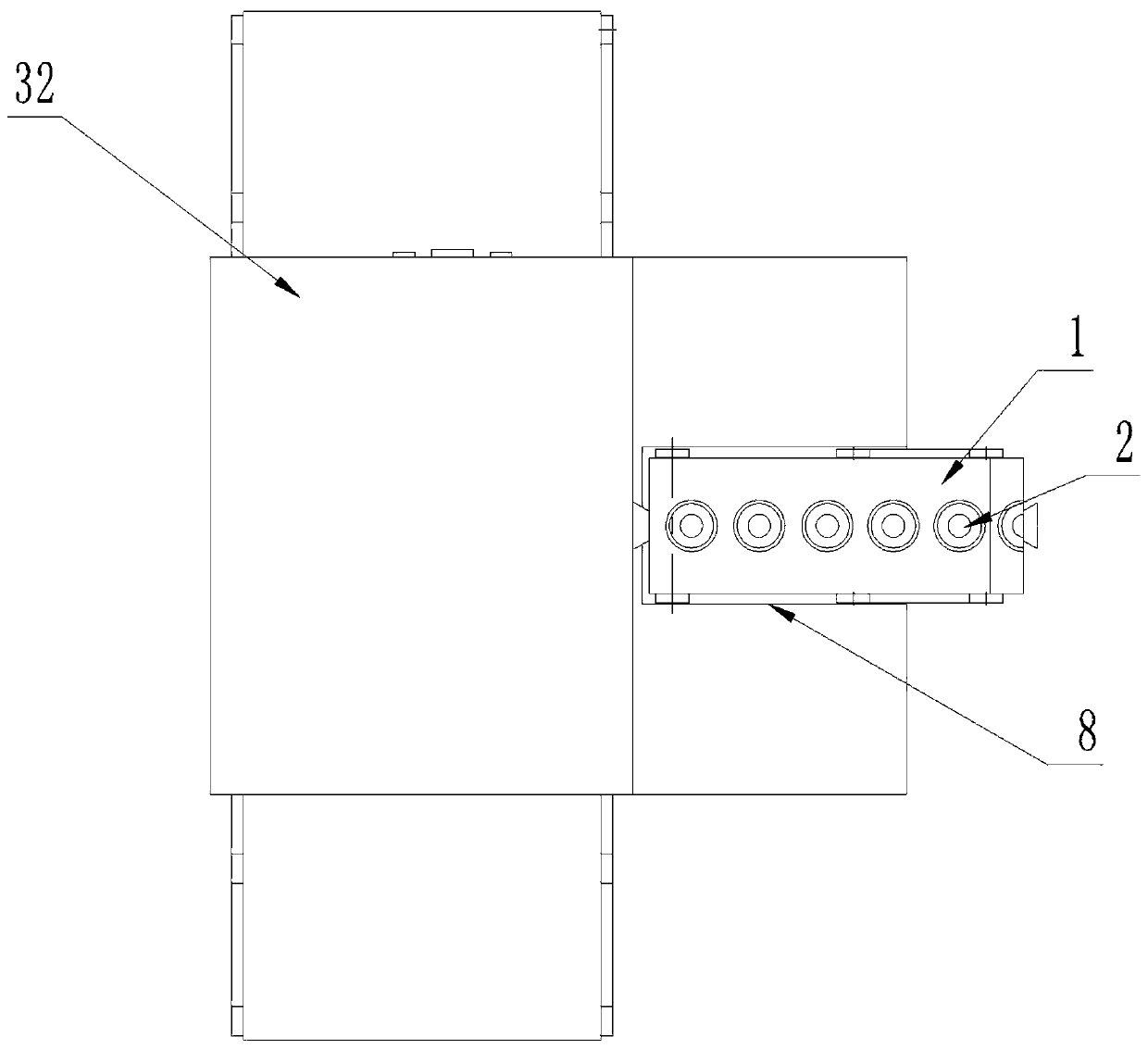

[0048] An automatic continuous apple packaging machine, comprising a frame 32, a conveying device for horizontally conveying apples is arranged on the upper side of the frame 32, and six rotating seats rotating around its longitudinal axis are arranged on the frame 32 on one side of the conveying device along the conveying direction. Frame 24, the six stations of the six turntables 24 are provided with packaging sleeves 23 that can be used to pick up apples, and the packaging sleeve 23 is provided with a sleeve-type six-bar foam supporter that can expand and contract independently 25. The lower side of the packaging sleeve 23 is provided with a foam net cutter 20 which can intermittently cut the mesh cover, and the bottom of the six turrets 24 is provided with a mesh support mechanism which can be connected with the six sleeves one by one. The bottom of the six turrets 24 There is a packing case tray 17 with a conveying mechanism, and a lifting mechanism is provided on the lowe...

Embodiment 2

[0052] This embodiment is further optimized on the basis of implementation 1, specifically:

[0053]The lower side of the frame 32 is provided with a plurality of universal casters 14 for walking and supporting, and the relative rotation in the frame 32 is provided with a net cover disc 9 that can wind the net cover, and the lifting mechanism is a hydraulic lift 13. Universal caster 14 installs the underside of frame 32, for the convenience of the present invention moves toward each direction, and the design of net cover dish 9 can be wound on the net cover dish 9 with uncut net cover, and frame 32 is provided with drive The power device for the rotation of the net cover disc 9, this power device can be a motor, and the net cover disc 9 rotates to convey the net cover to the net cover mechanism, which prevents the net cover from being pulled by the net cover mechanism when it is conveyed by itself, causing the net cover to be damaged, and the lifting Mechanism is set as hydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com