Method for preparing organic polymer through particle phase polymerization reaction

A polymerization reaction and polymer technology, which is applied in the field of preparing organic polymers by atomizing the polymerization raw materials to realize the particle phase polymerization reaction, can solve the problems of the degree of polymerization reaction and the restriction of reaction efficiency, and achieve wide contact interface, sufficient material reaction, Good heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] First, 0.12 g of ferric chloride initiator and 100 g of pyrrole distilled under reduced pressure were dissolved in 200 ml of deionized water to prepare a homogeneous pyrrole raw material solution.

[0036] Then the prepared pyrrole raw material solution is carried out according to the following steps:

[0037] (1) Put the prepared pyrrole raw material solution into the particle generator, and control the temperature of the pyrrole raw material solution in the particle generator to -5°C through the cooling tank outside the particle generator to prevent the pyrrole monomer from being oxidized Or a self-polymerization reaction occurs; use the ultrasonic atomizer equipped at the bottom of the particle generator to atomize the pyrrole raw material solution into suspended particles with a size of 1 μm by using an ultrasonic oscillation frequency of 2.0 MHz;

[0038] (2) Open the control valve of the carrier gas bottle, under the drive of the nitrogen gas with a pressure of 0....

Embodiment 2

[0041] First, 0.253g of benzoyl peroxide initiator was dissolved in 235g of methyl methacrylate distilled under reduced pressure to prepare a homogeneous methyl methacrylate raw material solution.

[0042] Then the prepared methyl methacrylate raw material solution is carried out according to the following steps:

[0043] (1) Put the prepared methyl methacrylate raw material solution into the particle generator, and control the temperature of the methyl methacrylate raw material solution in the particle generator to 0°C through the cooling tank provided outside the particle generator, To prevent the methyl methacrylate monomer from being oxidized or self-polymerized; use the ultrasonic atomizer equipped at the bottom of the particle generator to atomize the methyl methacrylate raw material solution into a size of 0.5 μm with an ultrasonic oscillation frequency of 2.4 MHz of suspended particles;

[0044] (2) Open the control valve of carrier gas cylinder, under the drive of th...

Embodiment 3-19

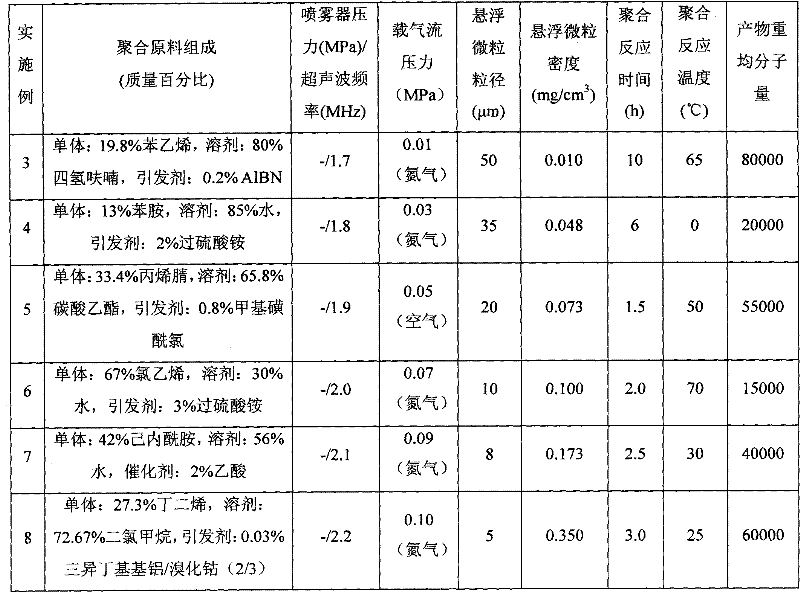

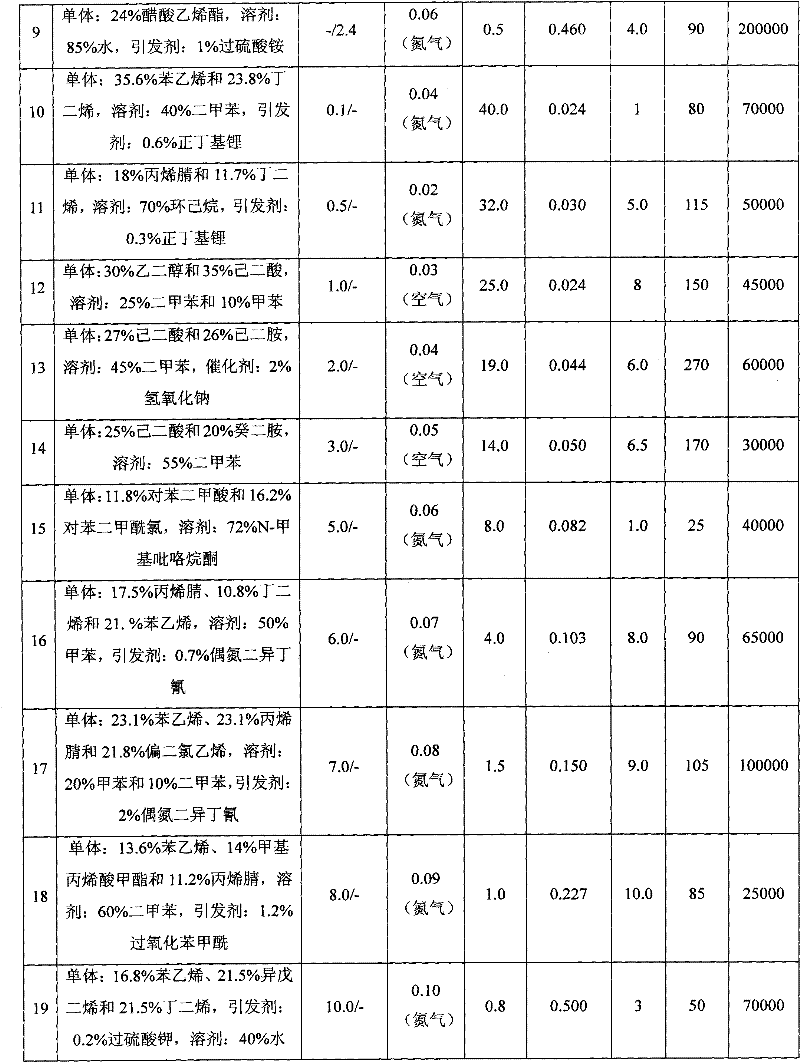

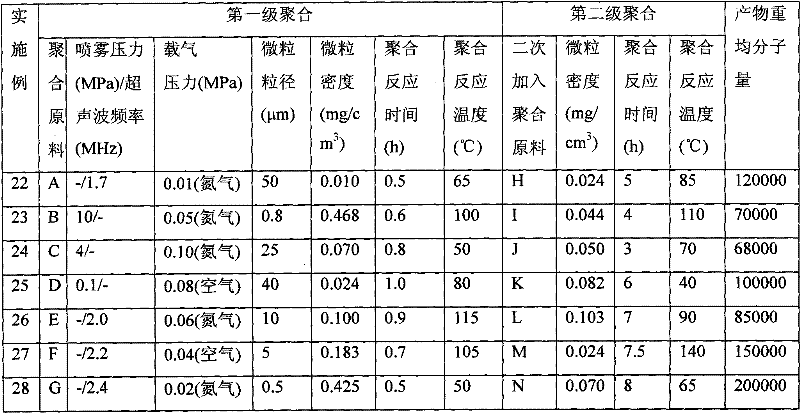

[0047] The polymerization reaction of embodiment 3-19 all adopts one-stage polymerization reaction, and its reaction step is with embodiment 1 or 2. Among them, one kind of polymerized monomer is used in embodiment 3-9, two kinds of polymerized monomers are used in embodiment 10-15, and three kinds of polymerized monomers are used in embodiment 16-19. Table 1 shows the composition and atomization conditions of different polymerized raw materials , carrier gas flow, polymerization reaction temperature and polymerization reaction time and other conditions, the organic polymer prepared.

[0048] Table I

[0049]

[0050]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com