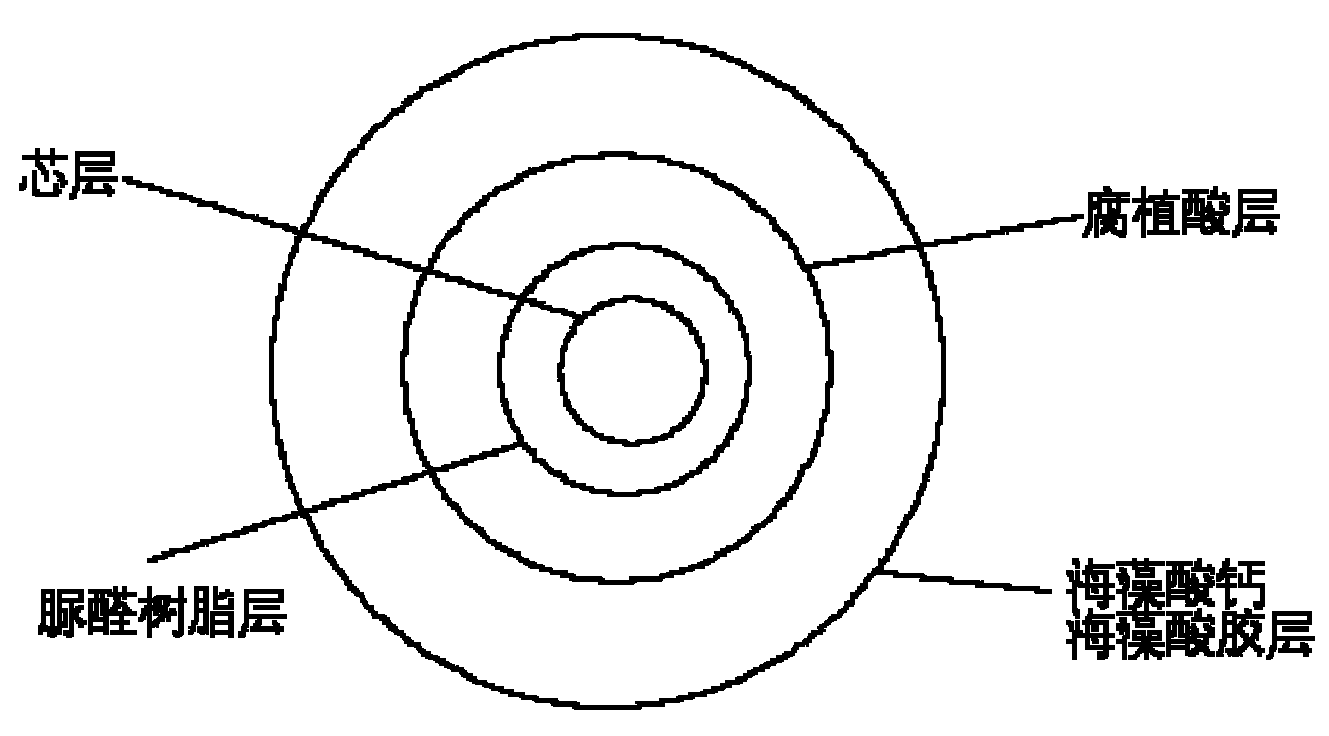

Algae sustained-release granular fertilizer, preparation method and application thereof

A slow-release granular fertilizer and seaweed technology, applied in application, fertilization equipment, fertilizer mixture, etc., can solve the problems of unstable slow-release performance, high production cost, complex process, etc., to reduce nutrient loss and improve nutrient utilization efficiency, and the effect of reducing agricultural costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Raw material name Weight percentage (%) Raw material name Weight percentage (%)

[0044] Calcium alginate Alginate gel 20 Urea-formaldehyde resin 20

[0045] Monoammonium Phosphate 10 Humic Acid 18

[0046] Urea 15 Potassium sulfate 15

[0047] Ferrous sulfate heptahydrate 2

[0048] The raw material calcium alginate alginate gel is prepared by the following steps:

[0049] 1) Grinding the seaweed raw material to 2×2cm;

[0050] 2) Add 10 kilograms of sodium carbonate to 990 kilograms of water, so that the concentration of sodium carbonate reaches 0.0943mol / L;

[0051] 3) Add step 2) to 1000 kilograms of sodium carbonate solution obtained in step 1) to form a mixture in 180 kilograms of seaweed obtained;

[0052]4) Degrade the mixture obtained in step 3) for 4 hours at 85°C under stirring, cool to normal temperature, and centrifuge to obtain 800 kg of supernatant;

[0053] 5) Add 4 kg of calcium chloride to the supernatant in step 4) to prepare calcium alginate al...

Embodiment 2

[0062] Raw material name Weight percentage (%) Raw material name Weight percentage (%)

[0063] Calcium Alginate Alginate Gum 15 Urea Formaldehyde Resin 15

[0064] Monoammonium Phosphate 15 Humic Acid 20

[0065] Urea 18 Potassium sulfate 16

[0066] Zinc sulfate heptahydrate 1

[0067] The raw material calcium alginate alginate gel is prepared by the following steps:

[0068] 1) Grinding the seaweed raw material to 3×3cm;

[0069] 2) Add 20 kilograms of sodium carbonate to 980 kilograms of water, so that the concentration of sodium carbonate reaches 0.1887mol / L;

[0070] 3) Add 200 kilograms of seaweeds obtained in step 1) to 1000 kilograms of sodium carbonate solution obtained in step 2) to form a mixture;

[0071] 4) Under stirring at 85°C, degrade the mixture obtained in step 3) for 4 hours, cool to normal temperature, and centrifuge to obtain 850 kg of supernatant;

[0072] 5) Add 6 kg of calcium chloride to the supernatant in step 4) to prepare calcium alginate al...

Embodiment 3

[0081] Raw material name Weight percentage (%) Raw material name Weight percentage (%)

[0082] Calcium alginate Alginate gel 10 Urea-formaldehyde resin 18

[0083] Monoammonium Phosphate 13 Humic Acid 20

[0084] Urea 18 Potassium sulfate 20

[0085] Manganese sulfate monohydrate 1

[0086] The raw material calcium alginate alginate gel is prepared by the following steps:

[0087] 1) Grinding the seaweed raw material to 4×4cm;

[0088] 2) Add 15 kilograms of sodium carbonate to 985 kilograms of water, so that the concentration of sodium carbonate reaches 0.1415mol / L;

[0089] 3) Add 150 kilograms of seaweeds obtained in step 1) to 1000 kilograms of sodium carbonate solution obtained in step 2) to form a mixture;

[0090] 4) Under stirring at 85°C, degrade the mixture obtained in step 3) for 4 hours, cool to normal temperature, and centrifuge to obtain 850 kg of supernatant;

[0091] 5) Add 5 kg of calcium chloride to the supernatant of step 4) to prepare calcium alginat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com