Cement-based grouting material containing modified naphthalene-series water reducing agent and preparation method thereof

A naphthalene-based water-reducing agent and grouting material technology, which can be used in climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of small slump loss over time, etc. Value, strength and bleeding rate improvement, the effect of increasing the water reduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

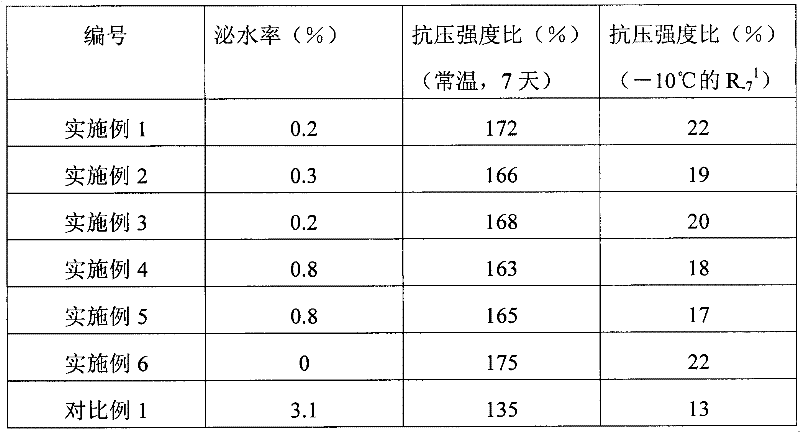

Examples

preparation Embodiment 1

[0027] Preparation of material A

[0028] Put 1400Kg of naphthalene and 200Kg of anthracene into the melting tank, melt and heat, when the temperature rises to about 90°C, press the molten naphthalene and anthracene into the sulfonation tank, keeping the pressure less than or equal to 0.1MPa. After heating the naphthalene and anthracene pressed into the sulfonation kettle to 130-135°C, add 1600Kg of concentrated sulfuric acid to carry out the sulfonation reaction for 3.5 hours. Then, add 1000Kg of water to carry out the hydrolysis reaction, when the acidity of the reaction system reaches about 28%, add 1000Kg of formaldehyde to carry out the condensation reaction, and the condensation reaction temperature is controlled at 100-110°C. After the condensation reaction was carried out for 3 hours, 1600 Kg of 50% sodium hydroxide aqueous solution was added for neutralization, so that the pH of the reaction system reached 8-10.

[0029] Preparation of material B

[0030]Add 3000kg ...

preparation Embodiment 2

[0033] Preparation of material A

[0034] The remaining steps are the same as in Preparation Example 1, except that 1400Kg of concentrated sulfuric acid is used for sulfonation.

[0035] Preparation of material B

[0036] Add 3000kg of water and about 300Kg of sodium hydroxide into the reaction kettle, stir evenly, add 600Kg of phenol, then continue stirring evenly, add 1000Kg of sulfamic acid, stir for 40 minutes, add 300Kg of formaldehyde dropwise into the reaction system and react for about 1 hour , add 450Kg p-aminobenzenesulfonic acid, then drop 700Kg formaldehyde into the reaction system, continue to react for half an hour, and obtain a liquid product. There is no need to provide external heat during the reaction process, only the heat generated by the reaction is collected and returned to the reactor through the circulation pipeline. After measurement, the molecular weight of the obtained condensation product is about 6200.

[0037] Mix material A and material B in a...

preparation Embodiment 3

[0039] Preparation of material A

[0040] Same as Preparation Example 1.

[0041] Preparation of material B

[0042] Add 3000kg of water and about 300Kg of sodium hydroxide into the reaction kettle, stir evenly, add 600Kg of phenol, then continue to stir evenly, add 1050Kg of sulfamic acid, stir for 40 minutes, add 350Kg of formaldehyde dropwise into the reaction system and react for about 1 hour , add 350Kg p-aminobenzenesulfonic acid, then drop 600Kg formaldehyde into the reaction system, continue to react for half an hour, and obtain a liquid product. There is no need to provide external heat during the reaction process, only the heat generated by the reaction is collected and returned to the reactor through the circulation pipeline. It is measured that the molecular weight of the obtained condensation product is about 6100.

[0043] Mix material A and material B in a ratio of 10:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com