System and method for producing hydrogen by controllably hydrolyzing sodium borohydride/aluminum powder mixed solid fuel

A technology of solid fuel and sodium borohydride, which is applied in the field of hydrogen storage and hydrogen production, can solve the problems of low hydrogen production efficiency and high cost of hydrogen production, and achieve the effects of high safety, easy operation and high hydrogen storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

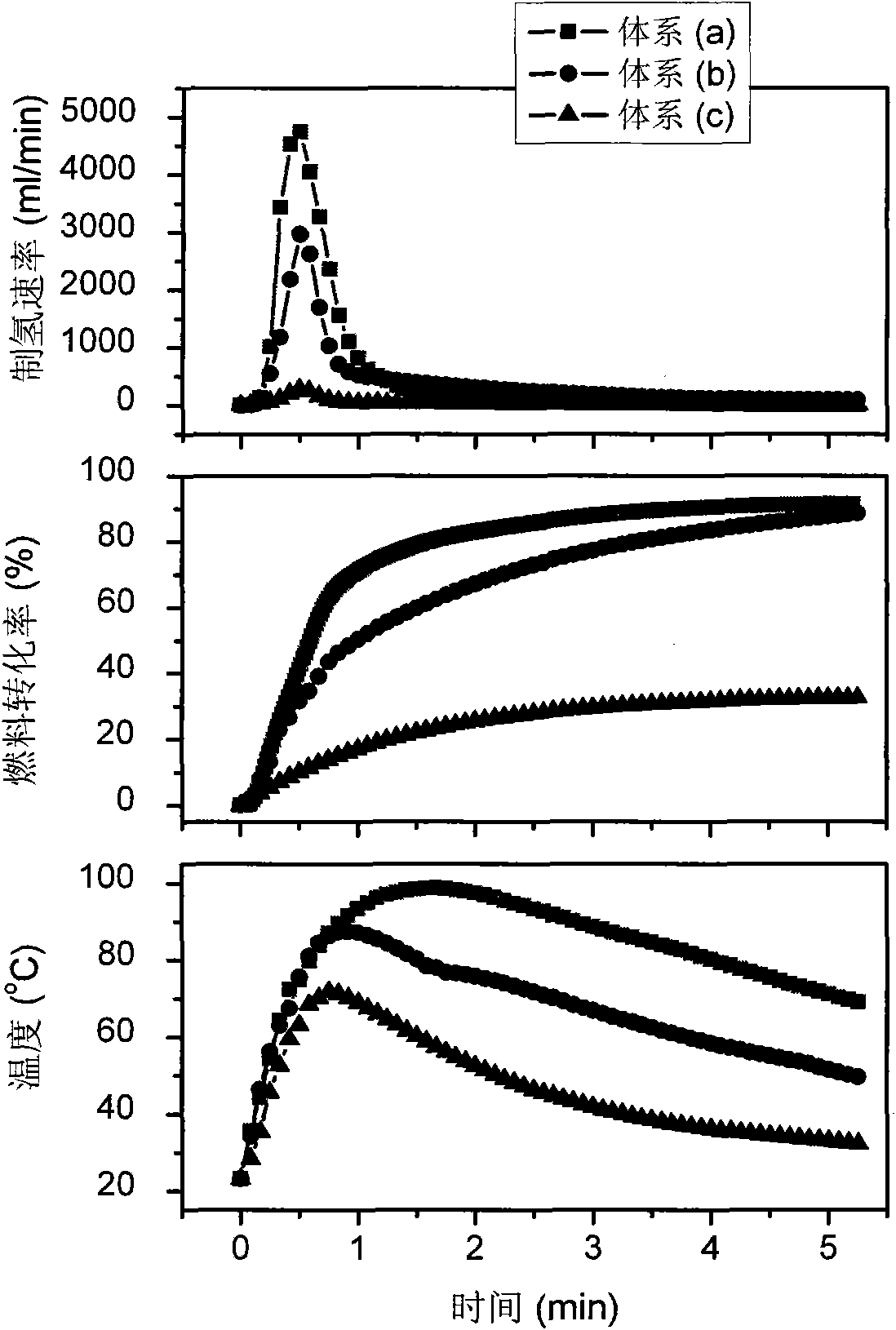

[0028] NaBH 4 Hydrogen production performance comparison between +Al mixed solid fuel hydrolysis hydrogen production system and single solid fuel hydrogen production system.

[0029] NaBH 4 + Al mixed solid fuel catalytic hydrolysis hydrogen production system construction:

[0030] (1) Preparation of solid fuel: quantitatively weigh 1g NaBH respectively 4, 0.5g of Al powder (average particle size 200μm) and 0.1g of NaOH, mixed uniformly in a mortar or in a ball mill jar.

[0031] (2) Preparation of liquid fuel: quantitatively weigh 0.15g of anhydrous CoCl 2 , which was dissolved in 2.85 g H 2 O, configure 3g 5wt.% CoCl 2 aqueous solution.

[0032] Single solid fuel catalytic hydrolysis hydrogen production system construction:

[0033] Use the same method to construct NaBH respectively 4 Single solid fuel catalytic hydrolysis system and Al / H 2 O catalytic reaction system.

[0034] Hydrogen production method:

[0035] The configured solid fuel mixture is placed in a c...

Embodiment 2

[0041] Liquid fuel flow rate versus NaBH 4 Effect of +Al mixed solid fuel on the hydrogen production performance of catalytic hydrolysis hydrogen production system.

[0042] NaBH 4 +Al mixed solid fuel catalytic hydrolysis hydrogen production system construction, hydrogen production method and hydrogen production performance test method are the same as in Example 1.

[0043] figure 2 The comparison of the maximum hydrogen production rate and fuel conversion rate of the mixed solid fuel catalytic hydrolysis hydrogen production system under different liquid fuel flow rates is given. When CoCl 2 When the titration rate of the aqueous solution is 0.8 and 2.5g / min, the maximum hydrogen production rate of the system is 2300 and 4450ml / min respectively, and the fuel conversion rate is 89 and 78%; the calculated hydrogen storage capacity of the system is 5.3 and 4.6 wt.%. The test results show that the hydrogen production performance of the mixed solid fuel catalytic hydrolysis ...

Embodiment 3

[0045] Using two non-noble metal salts as catalysts, a mixed solid fuel catalytic hydrolysis hydrogen production system was constructed.

[0046] NaBH 4 + Al mixed solid fuel catalytic hydrolysis hydrogen production system construction:

[0047] (1) Preparation of solid fuel: the solid fuel composition and preparation method are the same as in Example 1.

[0048] (2) Preparation of liquid fuel: quantitatively weigh 0.075g of anhydrous Co(Ac) respectively 2 and 0.075 g anhydrous FeCl 2 , which was dissolved in 2.85 g H 2 O, configure 3g 5wt.%[Co(Ac) 2 +FeCl 2 ] Aqueous solution.

[0049] The hydrogen production method and the hydrogen production performance test method are the same as in Example 1.

[0050] image 3 Given the use of Co(Ac) 2 +FeCl 2 The hydrogen production performance of the hybrid solid fuel catalytic hydrolysis hydrogen production system constructed by two catalysts. The test results show that: when the titration rate of the liquid fuel is 2.0g / min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com