Novel storage bin

A silo, a new type of technology, applied in the fields of chemical machinery and equipment technology, can solve problems such as difficulty in ensuring product quality, affecting fertilizer efficiency, and unstable product quality, avoiding secondary stratification, stable product quality, and low equipment cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

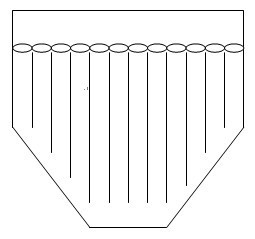

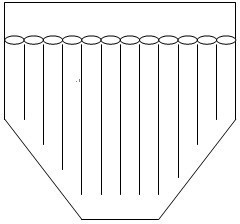

[0024] Such as figure 1 As shown, the unloading channel includes a plurality of unloading channels arranged in parallel, and the lower end of the unloading channel located directly above the closing slope of the lower bin body 2 in the unloading channel does not contact with the position of the corresponding closing slope. distance.

[0025] The above-mentioned distance should not be too large, otherwise the effect of avoiding delamination is not obvious, and it should not be too small, otherwise the material will not fall smoothly. The size of the distance can be selected to be the same as the pipe diameter of the feeding channel.

[0026] The above-mentioned distance between each feeding channel and its corresponding closing slope can be the same or different. When the same, the tapered surface formed at the lower end of the feeding channel directly above the closing slope is parallel to the closing slope.

[0027] The distance between the feeding channel directly above the...

specific Embodiment approach 2

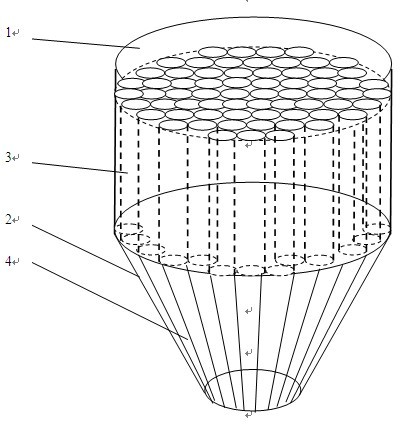

[0028] Such as figure 2 As shown, the feeding channel is provided with a feeding channel from the upper end surface of the silo to the bottom surface of the silo.

[0029] The upper unloading channel 3 located in the upper bin body 1 is a vertical channel arranged in parallel with each other, and the lower unloading channel 4 located in the lower bin body 2 starts from the junction of the lower bin body 2 and the upper bin body 1. The shrinkage shape, the shrinkage ratio is the same as the shrinkage ratio of the lower silo.

[0030] The present invention can be entirely made of metal or other anti-corrosion materials, and the silo can be widely used in dry powder, dry granule blending and stirring and cutting industries with different physical properties.

[0031] The cross-sectional shape of the feeding channel can be honeycomb, which has the advantages of compact structure and easy processing. At the same time, the angle formed between the cone busbar of the silo and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com