Process for producing hot rolling thin nonwoven fabric

A technology of non-woven fabrics and production technology, which is applied in the direction of non-woven fabrics, textiles, and papermaking. It can solve the problems of pilling and washability, and achieve the effects of smooth cloth surface, improved wash resistance, and improved fastness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

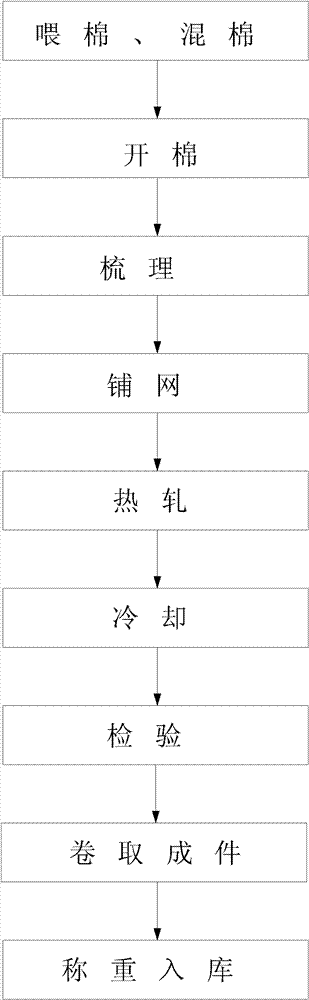

[0018] refer to figure 1 It is the embodiment one of a kind of hot-rolled thin nonwoven production process of the present invention, comprises the following steps successively:

[0019] A. Cotton feeding and cotton blending: put 75% polyester fiber, 5% nylon fiber, 7% viscose fiber and 13% ES fiber into the conveyor belt of the cotton feeding machine;

[0020] B. Cotton opening: the fiber raw material is transported from the cotton feeder to the cotton opener, and the fiber raw material is broken up;

[0021] C. Carding: Straighten out the fiber raw materials scattered in step B;

[0022] D. laying the net: superimposing the fiber raw materials straightened out in step C vertically and horizontally into multiple layers;

[0023] E. hot rolling: the fiber raw material stacked into multiple layers in step D is sent to a hot rolling mill, and the multi-layer fiber raw material is hot rolled into a nonwoven fabric by the hot rolling mill roll;

[0024] F. Cooling, inspection, c...

Embodiment 2

[0026] refer to figure 1 Be the embodiment two of a kind of hot-rolled thin nonwoven fabric production technology of the present invention, comprise the following steps successively:

[0027] A. Cotton feeding and cotton blending: put 70% polyester fiber, 7% nylon fiber, 8% viscose fiber and 15% ES fiber into the conveyor belt of the cotton feeding machine;

[0028] B. Cotton opening: the fiber raw material is transported from the cotton feeder to the cotton opener, and the fiber raw material is broken up;

[0029] C. Carding: Straighten out the fiber raw materials scattered in step B;

[0030] D. laying the net: superimposing the fiber raw materials straightened out in step C vertically and horizontally into multiple layers;

[0031] E. hot rolling: the fiber raw material stacked into multiple layers in step D is sent to a hot rolling mill, and the multi-layer fiber raw material is hot rolled into a nonwoven fabric by the hot rolling mill roll;

[0032] F. Cooling, inspect...

Embodiment 3

[0034] refer to figure 1 It is the embodiment three of a kind of hot-rolled thin nonwoven fabric production technology of the present invention, comprises the following steps successively:

[0035] A. Cotton feeding and cotton blending: put 80% polyester fiber by mass, 4% nylon fiber, 4% viscose fiber, and 12% ES fiber on the conveyor belt of the cotton feeding machine;

[0036] B. Cotton opening: the fiber raw material is transported from the cotton feeder to the cotton opener, and the fiber raw material is broken up;

[0037] C. Carding: Straighten out the fiber raw materials scattered in step B;

[0038] D. laying the net: superimposing the fiber raw materials straightened out in step C vertically and horizontally into multiple layers;

[0039] E. hot rolling: the fiber raw material stacked into multiple layers in step D is sent to a hot rolling mill, and the multi-layer fiber raw material is hot rolled into a nonwoven fabric by the hot rolling mill roll;

[0040] F. Coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com