Preparation method for mature vinegar

A technology of vinegar mash and acetic acid bacteria, applied in directions such as preparation of vinegar, biochemical equipment and methods, methods based on microorganisms, etc., can solve the problem of long after-ripening time (generally 1-3 months, unfavorable for mass production, mechanization) problems such as low intensity, to achieve the effect of easy mechanized operation, high labor efficiency, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] 3. Preparation of fried rice liquid:

[0032] Stir-fry the rice until it is burnt until it becomes dark brown and thick, then add 3 times the amount of the original rice to boil, boil for 4 to 5 minutes, and finally filter to get the fried rice liquid.

Embodiment 1

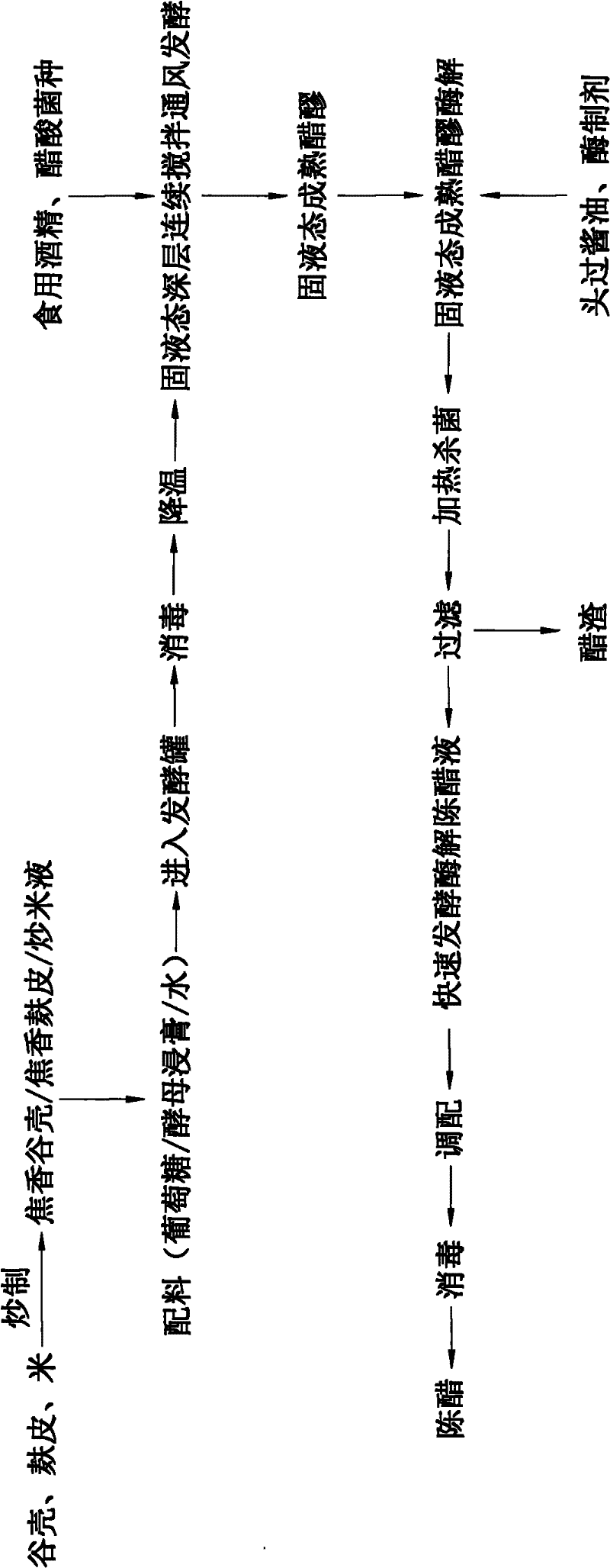

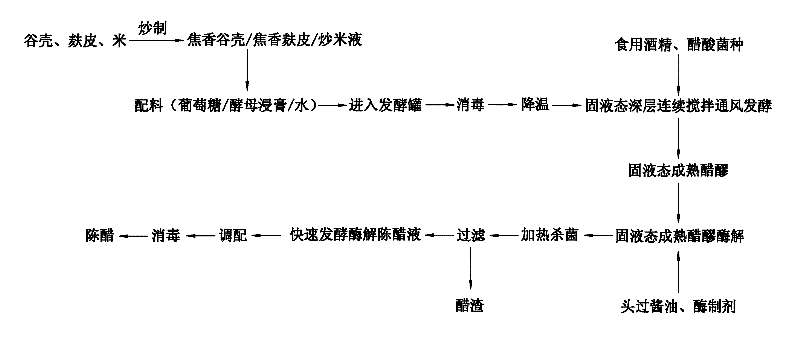

[0034] Such as figure 1 Shown is the process flow diagram of the mature vinegar preparation method of the present invention. The specific description is as follows:

[0035] 1. Prepare raw materials:

[0036] The ratio of raw materials is shown in the table below:

[0037]

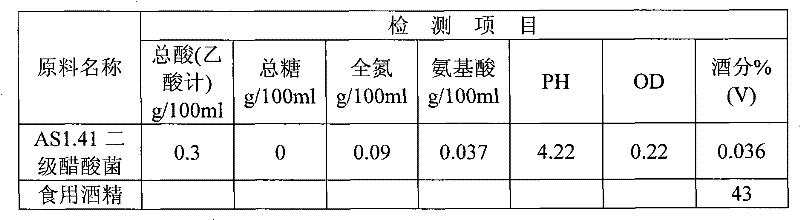

[0038] Pump the fried chaff, bran, fried rice liquid, glucose powder and yeast extract into the fermenter, carry out 100°C disinfection treatment, then cool down to 40-45°C, and then add edible alcohol and acetic acid bacteria.

[0039] 2. Carry out continuous stirring and ventilated fermentation in solid-liquid state:

[0040] 1) Under the condition of 31-33°C, continuous ventilation and stirring are carried out for heat preservation and fermentation. Fermentation time is 40~48 hours.

[0041] 2) Fermentation defoaming: use edible defoaming agent for defoaming. Add 50 grams of edible defoamer with the acetic acid bacteria (dissolved in hot water first) during the batching, and add 10 grams per ti...

Embodiment 2

[0072] The ratio of raw materials of this embodiment is shown in the table below:

[0073]

[0074] The fermentation data of this embodiment are shown in the table below.

[0075] fermentation time

[0076] Other processes in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com