Application of efficient dephosphorization agent in wastewater treatment

A high-efficiency dephosphorization agent and wastewater treatment technology, applied in the field of water treatment, can solve the problems of ineffective water treatment chemicals, negative impact on water quality, and high treatment costs, reduce the amount of sludge generated and the difficulty of treatment, and reduce raw water. Influence of water quality, effect of chemical stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

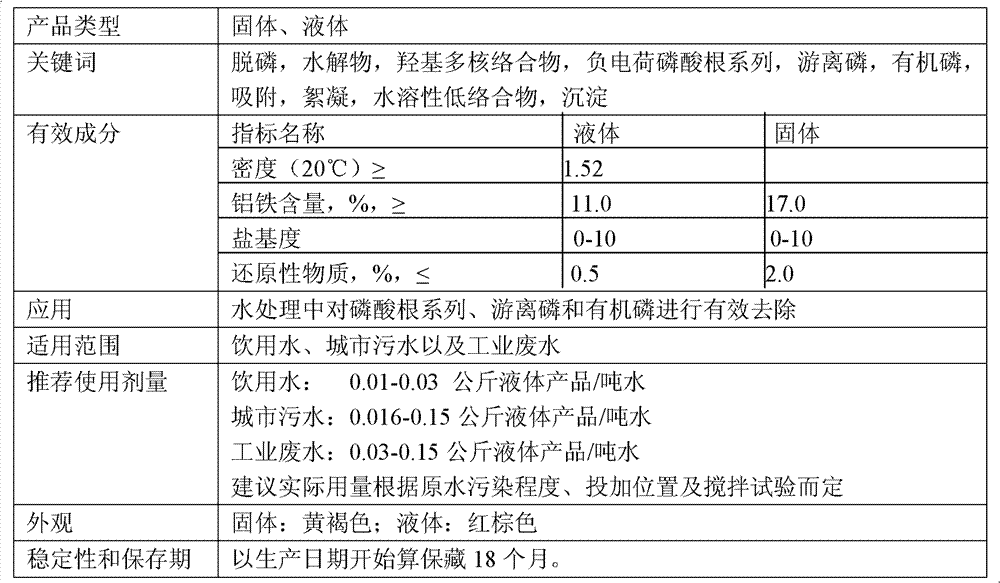

Image

Examples

Embodiment 1

[0031] Take 22.5% of aluminum sulfate, 27.5% of iron sulfate, 17.5% of sodium hypochlorite, and 32.5% of water.

[0032] Add tap water to the reaction kettle according to the formula, turn on electric stirring, heat to 40°C, add solid aluminum sulfate and ferric sulfate, stir and dissolve completely, add sodium hypochlorite in several times to carry out polymerization reaction, after 4 hours of reaction, then heat up to 80°C Stable aging for 12 hours, filtered with 400-mesh polyester cloth to obtain a transparent liquid product.

Embodiment 2

[0034] Take 30% of aluminum sulfate, 20% of iron sulfate, 15% of sodium hypochlorite, and 35% of water.

[0035] Add tap water to the reaction kettle according to the formula, turn on electric stirring, heat to 45°C, add solid aluminum sulfate and ferric sulfate, stir to dissolve completely, add sodium hypochlorite in several times to carry out polymerization reaction, react for 4 hours, and then heat up to 85°C Stable aging for 12 hours, filtered with 400-mesh polyester cloth to obtain a transparent liquid product. The liquid product is dried by a dryer and crushed to obtain a solid granular high-efficiency dephosphorization agent. Dosing point during wastewater treatment: the outlet of the aeration tank; dosing method: first dilute to 20% concentration of diluent, so that the agent is evenly dispersed, fully reacted with water, stirred evenly and then added to the wastewater.

[0036] Dosage (mg / L)

Embodiment 3

[0038] Take 25% of aluminum sulfate, 25% of iron sulfate, 17.5% of sodium hypochlorite, and 32.5% of water.

[0039] Add tap water to the reaction kettle according to the formula, turn on electric stirring, heat to 50°C, add solid aluminum sulfate and iron sulfate, stir and dissolve completely, add sodium hypochlorite in several times to carry out polymerization reaction, after reacting for 6 hours, then heat up to 85°C Steady aging for 8 hours, filtered with 400-mesh polyester cloth to obtain a transparent liquid product. Dosing point during wastewater treatment: the outlet of the aeration tank; dosing method: first dilute to 20% concentration of diluent, so that the agent is evenly dispersed, fully reacted with water, stirred evenly and then added to the wastewater.

[0040] Dosage (mg / L)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com