Adsorbing agent for eliminating S4O2<-> in acid mine wastewater and preparation method thereof

A technology for acid mine wastewater and adsorbent, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve the problems of secondary pollution, high operating cost, low pH value, etc., and reduce the cost of reagents , the effect of high selectivity and low chemical cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

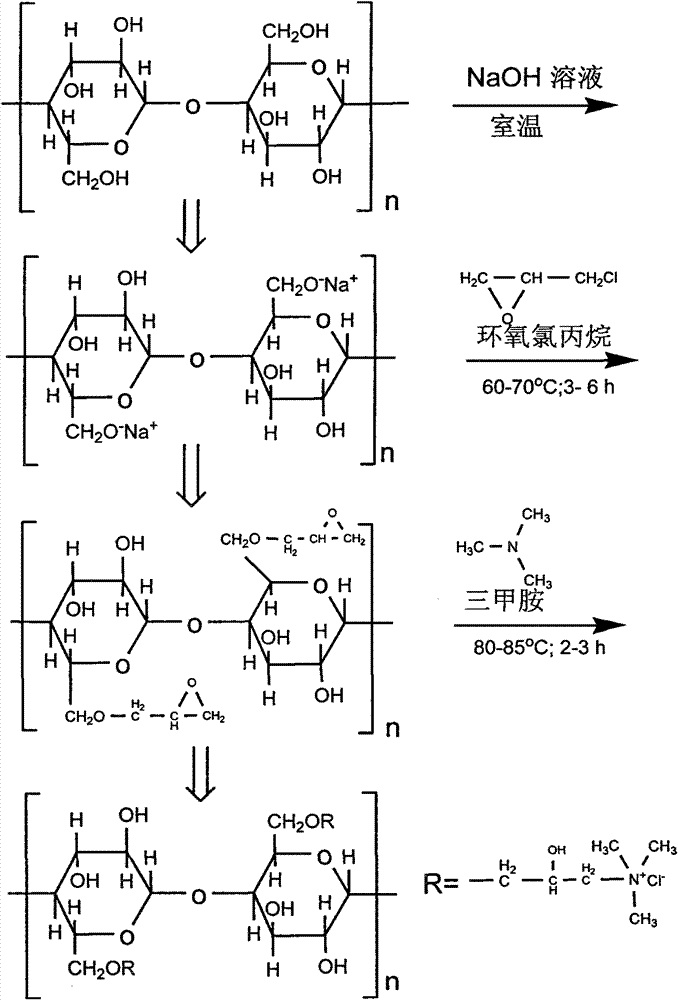

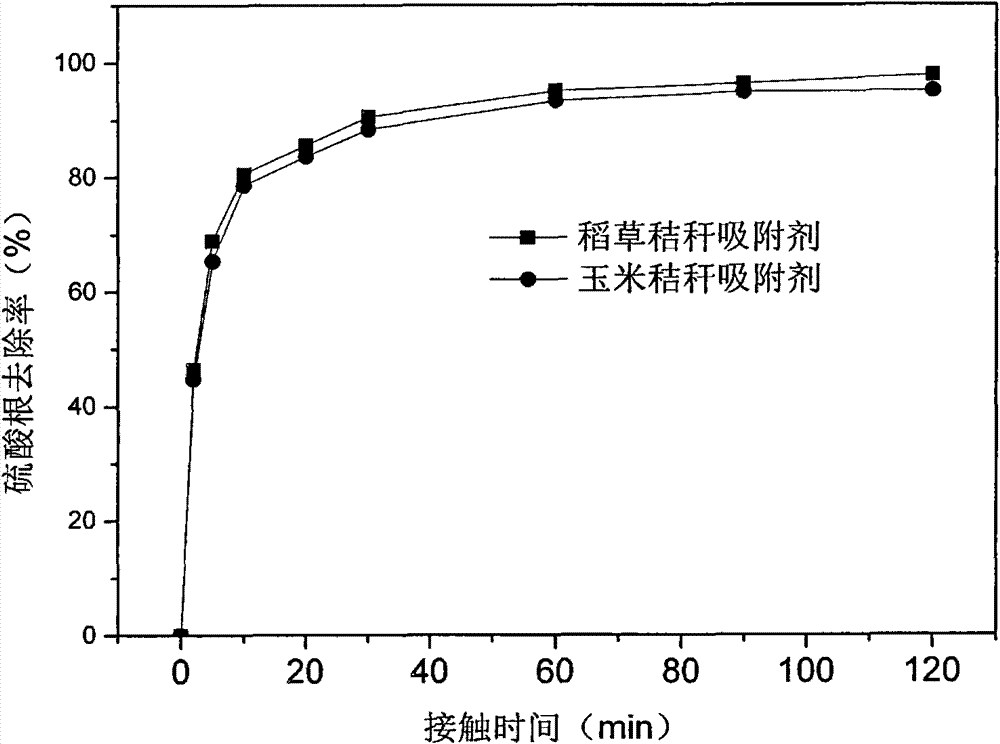

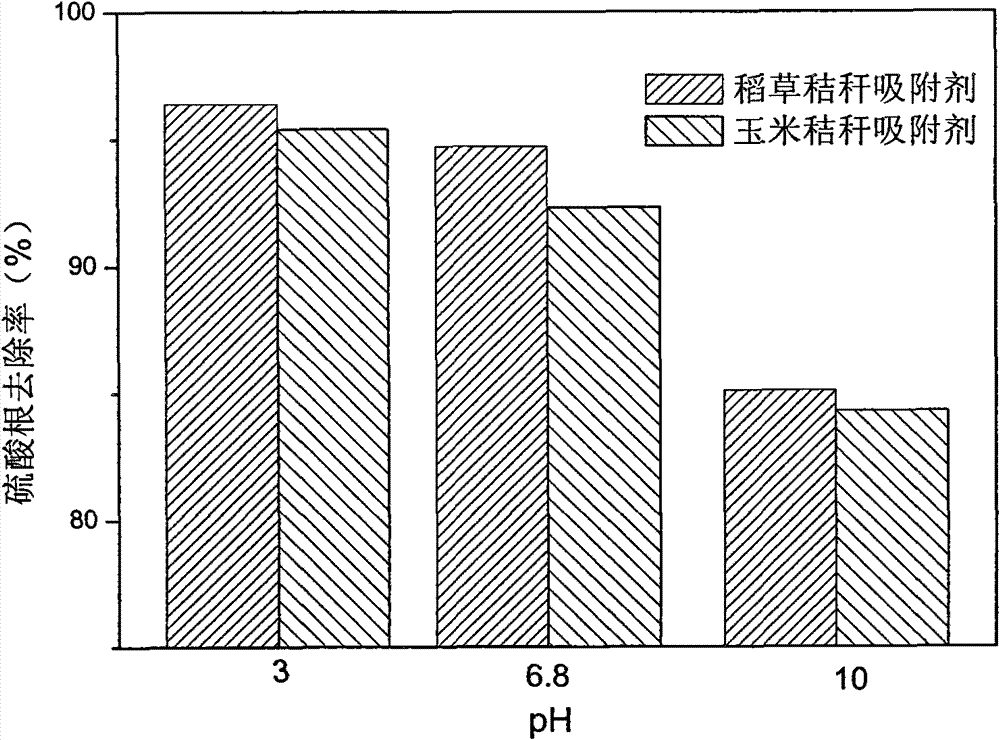

[0031] Preparation of rice straw adsorbent and its removal to simulate SO in AMD 4 2-

[0032]Wash, dry, and pulverize the rice straw in turn for later use, weigh 6g of spare rice straw raw material (20-40 mesh) into a conical flask, add 200ml of NaOH solution with a mass concentration of 18%, soak at room temperature for 3 hours, and carry out alkali processing. The alkalized rice straw was pressed and filtered to remove water, and then reacted with 60ml of pure epichlorohydrin at 65°C for 6h. After the above reaction was completed, the remaining epichlorohydrin was recovered by filtration. Add 60ml of 33% (w / w) trimethylamine aqueous solution to the reaction system, and react at 80°C for 3h. The solid phase product obtained in the reaction was washed with ethanol with a volume ratio of 1:1, 0.1M NaOH and 0.1M HCl in sequence, and finally washed with deionized water until the washing liquid was neutral, and dried at 60°C to obtain the straw adsorbent .

[0033] Depend on...

Embodiment 2

[0036] Preparation of corn straw adsorbent and its removal to simulate SO in AMD 4 2-

[0037] The corn stalks were cleaned, dried, and pulverized in turn, and then used for later use. Weighed 6 g of spare corn stalk raw materials into an Erlenmeyer flask, added 200 ml of 10% NaOH solution, stood at room temperature and soaked for 12 hours, and carried out alkalization treatment. The alkalized rice straw was suction-filtered to remove water, and then reacted with 60ml of pure epichlorohydrin at 70°C for 3 hours. After the above reaction was completed, the remaining epichlorohydrin was recovered by filtration. Add 60ml of 33% (w / w) trimethylamine aqueous solution to the reaction system, and react at 85°C for 2h. The solid phase product obtained by the reaction was washed with ethanol at a volume ratio of 1:1, 0.1M NaOH and 0.1M HCl in sequence, and finally washed with deionized water until the washing liquid was neutral, and dried at 60°C to obtain the straw adsorbent .

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com