Control device and control method for femto-second laser filament-forming and super-continuous radiation

A technology of supercontinuum radiation and femtosecond laser, which is applied in the field of femtosecond laser filament formation and control device of supercontinuum radiation, and can solve problems such as randomness of multifilaments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

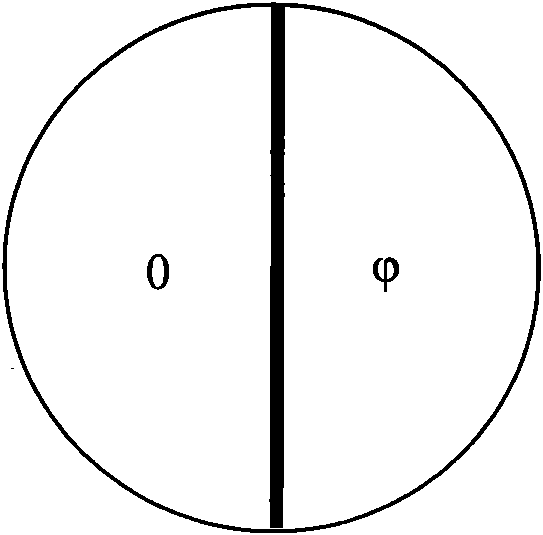

[0026] The following is an example of using a two-zone phase plate. The structure of the phase plate is as follows: figure 1 As shown, a layer of dielectric film in a semicircular area is coated on the surface of K9 glass, and the phase jump variable corresponding to the film thickness is That is, the phase plate is divided into two equal parts: the left semicircle area and the right semicircle area, which provide phase delays of 0 and π respectively. Suppose the incident light wavelength is 0.8μm, the spot is Gaussian distribution and the spot diameter is 10mm(1 / e 2 ).

[0027] After the light with a wavelength of 0.8 μm passes through the phase plate, there will be a phase difference of π between the left semicircle and the right semicircle of the light spot. After focusing with the lens, there will be two focus spots on the left and right in the focus area, and there is a phase difference of π between the two spots. Under the action of diffraction, self-focusing and pla...

Embodiment 2

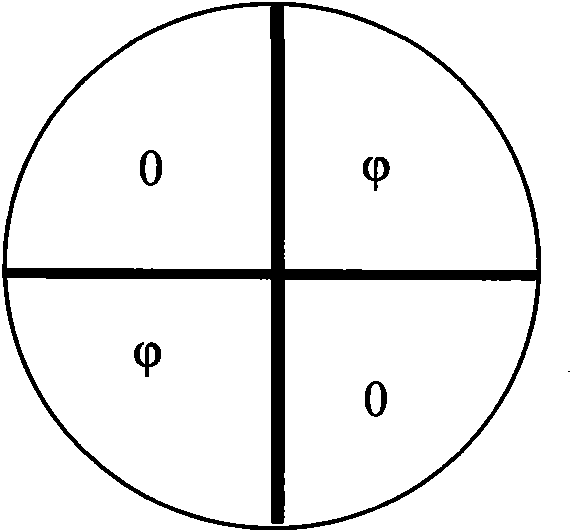

[0031] Let's continue to use a four-zone phase plate as an example. The structure of the phase plate is as follows figure 2 As shown, a circular dielectric film with four sectors is coated on the surface of K9 glass, and the phase jump variable corresponding to the film thickness is That is, the phase plate is divided into four equal parts: the upper left semicircle area, the lower left semicircle area, the upper right semicircle area and the lower right semicircle area, providing phase delays of 0, π, π, 0 respectively.

[0032] see again Figure 5 , Figure 5 It is the optical path diagram of Embodiment 2 of the femtosecond laser using four-zone phase plate to form four filaments and the supercontinuum radiation control device of the present invention;

[0033] After the light with a wavelength of 0.8 μm passes through the four-zone phase plate, the phase zone of the spot is divided into upper left semicircle, lower left semicircle, upper right semicircle, and lower ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com