Vertical axis wind driven generator with balanced torque

A technology of wind power generator and torque balance, which is applied to wind power generators, wind power motor combinations, wind power generators at right angles to the wind direction, etc. It can solve the problems of wind power generator power generation efficiency decline, blade 4 rotation failure, and blade 4 speed reduction, etc. , to achieve the effect of enhanced power generation, smooth rotation and high power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

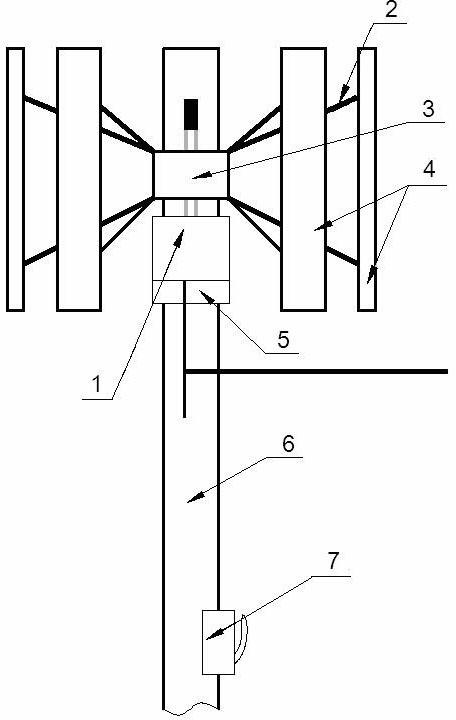

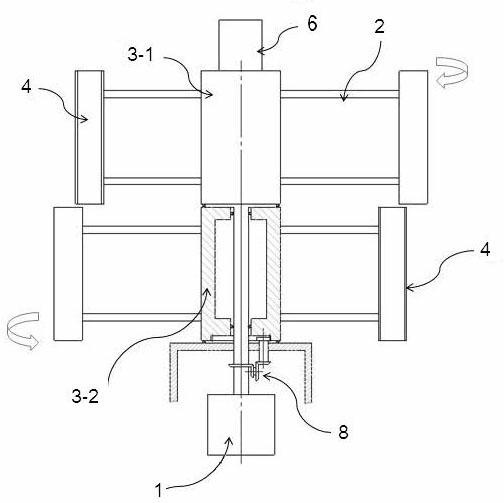

[0020] Such as Figure 2 ~ Figure 4 As shown, the present invention is a torque-balanced vertical-axis wind power generator, which includes a column 6 , multi-stage impellers and a generator 1 . The impeller consists of a hub 3, connecting rods 2 and blades 4. The hub 3 is axially and vertically arranged on the column 6, that is, the hub 3 is arranged horizontally perpendicular to the column 6. The outer peripheral surface of the hub 3 is connected by several connecting rods 2. Several groups of blades 4 . The hub 3 is connected to the main shaft of the generator 1, and the motion state of the impeller is transmitted to the power generator 1, so that the main shaft of the generator 1 rotates, thereby doing work to generate electric energy.

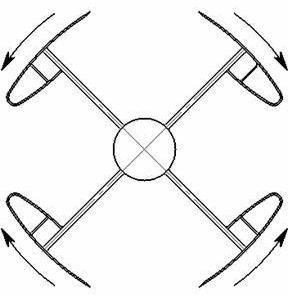

[0021] The multi-stage impellers of the wind power generator can be divided into two types: forward impellers and counter-rotating impellers according to the direction of rotation. The forward rotation and reverse rotation are relative t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com