Preparation method of diglyceride-enriched functional oil

A diacylglycerol and functional technology, which is applied in the field of preparation of functional oils rich in diacylglycerol, can solve the problems of unfavorable food system application, organic solvent residue, and many by-products, and achieve good industrial application prospects, The effect of product cost reduction and good catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh 5 g of activated DA-201 macroporous adsorption resin, 10 g of Tris-HCl buffer solution, and 1 g of free phospholipase Lecitase ?Ultra mixed, stirred and adsorbed at 25°C for 2 hours, and then filtered to obtain a macroporous adsorption resin immobilized phospholipase with an enzyme activity of 1850 U / g. Vacuum dried and set aside.

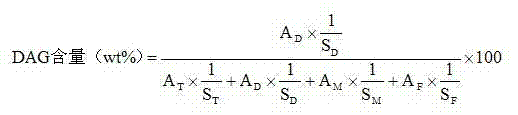

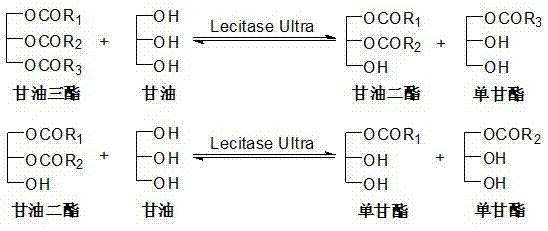

[0031] Weigh 10g of refined soybean oil in a flask, place it in a constant temperature magnetic stirrer, add 100g of glycerol, 10g of water and 5g of immobilized phospholipase Lecitase ? Ultra, set the reaction temperature at 40° C., and react for 24 hours at a stirring speed of 200 r / min. After the reaction, the reaction mixture was poured into a centrifuge tube and centrifuged at 8000×g for 20 min. The upper oil layer is the functional oil rich in diglyceride, and the middle layer is the immobilized phospholipase Lecitase ? Ultra particles, the lower layer is unreacted glycerin. The upper oil layer was taken, and the diglycerid...

Embodiment 2

[0033] Weigh 5 g of activated DA-201 macroporous adsorption resin, 20 g of Tris-HCl buffer solution, and 1 g of free phospholipase Lecitase ? Ultra mixed, stirred and adsorbed at 30°C for 4 hours, and then filtered to obtain a macroporous resin-immobilized phospholipase with an enzyme activity of 1462 U / g. Vacuum dried and set aside.

[0034] Weigh 10g of refined palm oil in a flask, place in a constant temperature magnetic stirrer, add 80g of glycerin, 5g of water and 6g of immobilized phospholipase Lecitase ? Ultra, set the reaction temperature at 45° C., and react for 36 hours at a stirring speed of 300 r / min. After the reaction, the reaction mixture was poured into a centrifuge tube and centrifuged at 10000×g for 15 min. The upper oil layer is the functional oil rich in diglyceride, and the content of diglyceride is 51.7 wt% as determined by high performance liquid chromatography. After the phospholipase immobilized on the macroporous adsorption resin was reused 10 ti...

Embodiment 3

[0036] Weigh 5 g of activated DA-201 macroporous adsorption resin, 20 g of Tris-HCl buffer solution, and 1 g of free phospholipase Lecitase ? Ultra mixed, stirred and adsorbed at 35°C for 3 hours, and then filtered to obtain a macroporous adsorption resin immobilized phospholipase with an enzyme activity of 1344 U / g. Vacuum dried and set aside.

[0037] Weigh 10g of refined peanut oil in a flask, place it in a constant temperature magnetic stirrer, add 50g of glycerin, 8g of water and 8g of immobilized phospholipase Lecitase ? Ultra, set the reaction temperature at 35° C., and react for 24 hours at a stirring speed of 250 r / min. After the reaction, the reaction mixture was poured into a centrifuge tube and centrifuged at 6000×g for 30 min. The upper oil layer is the functional oil rich in diglyceride, and the content of diglyceride is 52.5 wt% as determined by high performance liquid chromatography. After the phospholipase immobilized on the macroporous adsorption resin w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com