Method for quick pyrolysis of coal direct liquefaction residues by utilizing microwaves

A technology for direct liquefaction of coal and residues, which is used in the preparation of liquid hydrocarbon mixtures, special forms of dry distillation, and petroleum industry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

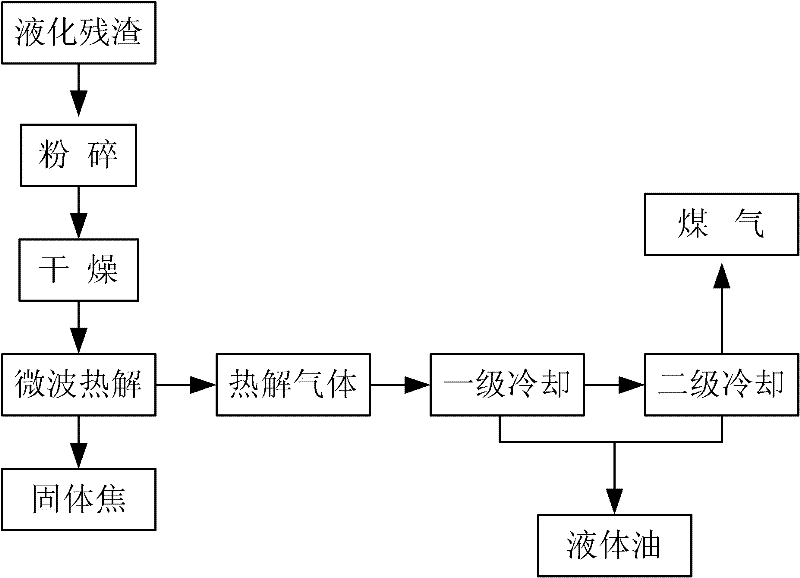

[0022] As shown in Figure 1, the method for utilizing microwave fast pyrolysis coal to directly liquefy residue is characterized in that it comprises the following steps:

[0023] The first step is to use the grinding equipment to crush the coal direct liquefaction residue to a particle size of 30mm;

[0024] In the second step, the pulverized coal direct liquefaction residue is dried in a drying device at 100°C for 20 minutes;

[0025] The third step is to place the dried coal direct liquefaction residue in a microwave pyrolysis reactor, turn on the power, set the microwave frequency for heating to 2450MHz, heat to 900°C, and stay for 15 minutes to obtain solid coke and pyrolysis gas;

[0026] In the fourth step, the solid coke is collected after being cooled to normal temperature by the water cooling system, and the pyrolysis gas is collected through the primary air cooling system and the secondary liquid phase condensation system to separate liquid oil and gas.

Embodiment 2

[0028] As shown in Figure 1, the method for utilizing microwave fast pyrolysis coal to directly liquefy residue is characterized in that it comprises the following steps:

[0029] The first step is to use the grinding equipment to crush the coal direct liquefaction residue to a particle size of 10mm;

[0030] In the second step, the pulverized coal direct liquefaction residue is dried in a drying device at 100°C for 30 minutes;

[0031] The third step is to place the dried coal direct liquefaction residue in a microwave pyrolysis reactor, turn on the power, set the microwave frequency for heating to 2450MHz, heat to 800°C, and stay for 10 minutes to obtain solid coke and pyrolysis gas;

[0032] In the fourth step, the solid coke is collected after being cooled to normal temperature by the water cooling system, and the pyrolysis gas passes through the primary air cooling system and the secondary liquid phase condensation system to separate liquid oil and gas and collect them se...

Embodiment 3

[0034] As shown in Figure 1, the method for utilizing microwave fast pyrolysis coal to directly liquefy residue is characterized in that it comprises the following steps:

[0035] The first step is to use the grinding equipment to crush the coal direct liquefaction residue to a particle size of 5mm;

[0036] In the second step, the pulverized coal direct liquefaction residue is dried in a drying device at 100°C for 40 minutes;

[0037] The third step is to place the dried coal direct liquefaction residue in a microwave pyrolysis reactor, turn on the power, set the microwave frequency for heating to 915MHz, heat to 500°C, and stay for 5 minutes to obtain solid coke and pyrolysis gas;

[0038] In the fourth step, the solid coke is collected after being cooled to normal temperature by the water cooling system, and the pyrolysis gas passes through the primary air cooling system and the secondary liquid phase condensation system to separate liquid oil and gas and collect them separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com